Kevlar laminate offers superior flexibility and lightweight protection compared to steel plates, making it ideal for pet armor where comfort and mobility are crucial. Unlike steel plates, Kevlar effectively absorbs and disperses impact without adding significant weight, reducing strain on pets during movement. Its resistance to punctures and abrasions ensures enhanced durability while maintaining ease of wear for active animals.

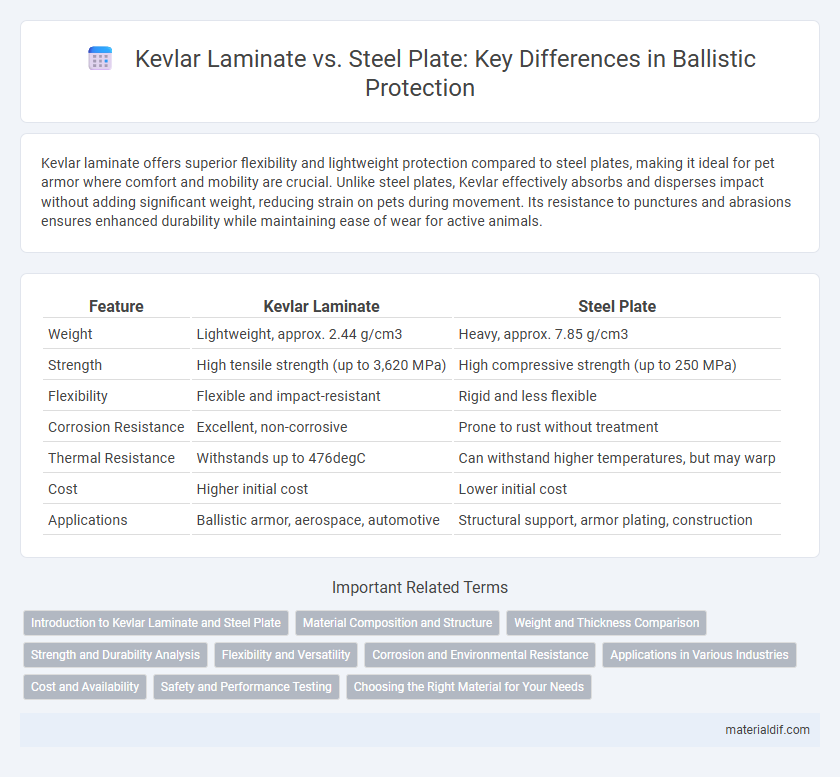

Table of Comparison

| Feature | Kevlar Laminate | Steel Plate |

|---|---|---|

| Weight | Lightweight, approx. 2.44 g/cm3 | Heavy, approx. 7.85 g/cm3 |

| Strength | High tensile strength (up to 3,620 MPa) | High compressive strength (up to 250 MPa) |

| Flexibility | Flexible and impact-resistant | Rigid and less flexible |

| Corrosion Resistance | Excellent, non-corrosive | Prone to rust without treatment |

| Thermal Resistance | Withstands up to 476degC | Can withstand higher temperatures, but may warp |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Ballistic armor, aerospace, automotive | Structural support, armor plating, construction |

Introduction to Kevlar Laminate and Steel Plate

Kevlar laminate consists of multiple layers of woven Kevlar fibers bonded with resin to create a lightweight, high-strength composite material known for exceptional impact resistance and flexibility. Steel plate, typically made of hardened or tempered steel, offers superior rigidity, hardness, and ballistic protection but with significantly increased weight compared to Kevlar laminate. Kevlar laminate is favored in applications requiring mobility and reduced weight, while steel plates are chosen for maximum durability and penetration resistance.

Material Composition and Structure

Kevlar laminate consists of woven para-aramid fibers combined with a resin matrix, creating a lightweight, flexible composite known for high tensile strength and impact resistance. Steel plates are composed of dense, metallic iron-carbon alloys that provide rigidity and superior compressive strength but at significantly higher weight. The layered fiber structure in Kevlar laminate dissipates energy effectively, whereas steel's crystalline lattice offers resistance through hardness and ductility.

Weight and Thickness Comparison

Kevlar laminate offers significant advantages over steel plate in weight and thickness, with Kevlar being up to five times lighter and considerably thinner for equivalent ballistic protection. Typically, a Kevlar laminate can achieve the same level of impact resistance as a steel plate at about 1/5th the weight and nearly 40-60% reduction in thickness. This weight and thickness efficiency makes Kevlar laminates ideal for applications requiring high-performance armor with enhanced mobility and reduced fatigue.

Strength and Durability Analysis

Kevlar laminate exhibits superior tensile strength and impact resistance compared to steel plates, making it ideal for applications requiring lightweight yet durable materials. Its high strength-to-weight ratio allows Kevlar to absorb and disperse energy effectively, outperforming steel in scenarios involving ballistic and blunt force impacts. While steel plates offer exceptional hardness and compressive strength, Kevlar laminates maintain structural integrity without the weight penalty, ensuring enhanced durability in dynamic environments.

Flexibility and Versatility

Kevlar laminate offers superior flexibility compared to steel plates, allowing for easier shaping and conforming to complex surfaces without compromising strength. Its lightweight nature enhances versatility in various applications, from body armor to aerospace components, where steel's rigidity and weight can limit usability. Kevlar's ability to absorb energy and resist impact while maintaining pliability makes it a preferred choice over steel for dynamic protective solutions.

Corrosion and Environmental Resistance

Kevlar laminate offers superior corrosion resistance compared to steel plates, as it is inherently non-metallic and immune to rust and chemical degradation. Its environmental resistance includes excellent performance in harsh weather conditions, UV exposure, and moisture without losing mechanical integrity. Steel plates, while strong, require protective coatings or treatments to prevent corrosion, which can deteriorate over time and reduce durability in challenging environments.

Applications in Various Industries

Kevlar laminate offers superior impact resistance and lightweight properties compared to steel plates, making it ideal for aerospace, automotive, and personal protective equipment applications. Industries such as military and law enforcement rely on Kevlar composites for ballistic vests and helmets due to enhanced flexibility and corrosion resistance. In contrast, steel plates remain preferred for heavy-duty industrial machinery and infrastructure where maximum hardness and durability are critical.

Cost and Availability

Kevlar laminate offers a cost-effective alternative to steel plates, with lower manufacturing and material expenses, making it accessible for various protective applications. Its availability is generally higher due to simpler production processes and widespread raw material sourcing compared to steel plates. The lightweight nature of Kevlar laminates also reduces transportation and handling costs, enhancing overall affordability.

Safety and Performance Testing

Kevlar laminate offers superior impact resistance and energy absorption compared to steel plates, making it highly effective in ballistic safety applications. Performance testing shows Kevlar laminates significantly reduce penetration and blunt force trauma, while maintaining lightweight and flexibility advantages over steel. Safety evaluations confirm Kevlar's ability to withstand multiple hits without structural failure, enhancing protective gear durability in high-threat environments.

Choosing the Right Material for Your Needs

Kevlar laminate offers superior tensile strength-to-weight ratio compared to steel plates, making it ideal for applications requiring lightweight yet durable protection, such as body armor and aerospace components. Steel plates provide exceptional hardness and impact resistance, suitable for heavy-duty environments like construction and vehicle armor, but with increased weight and reduced flexibility. Selecting the right material depends on balancing factors like weight constraints, impact resistance requirements, and environmental conditions specific to your project.

Kevlar Laminate vs Steel Plate Infographic

materialdif.com

materialdif.com