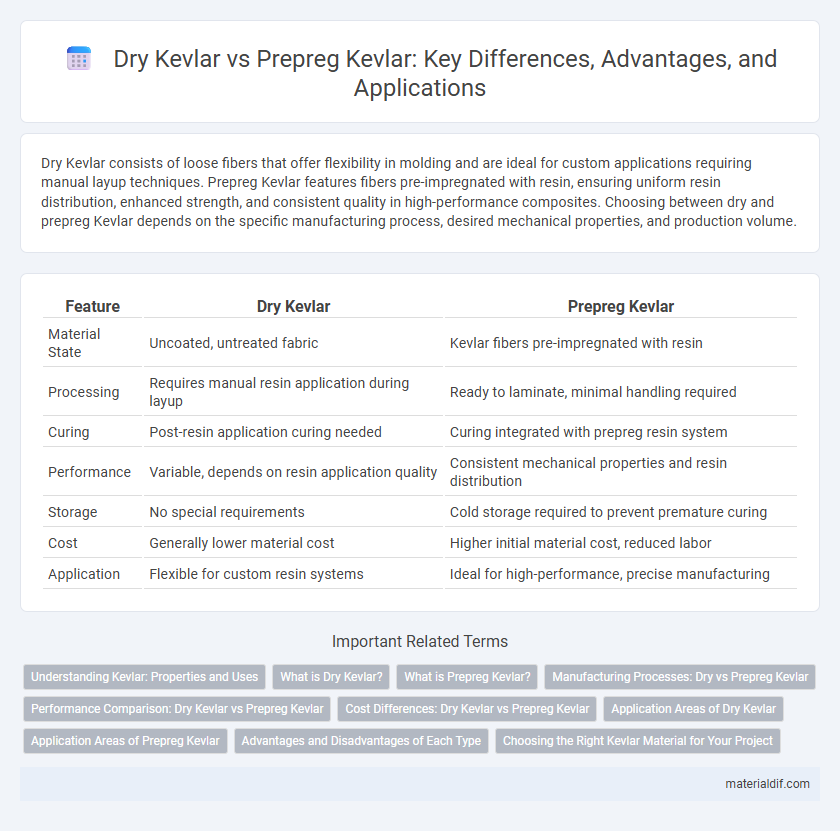

Dry Kevlar consists of loose fibers that offer flexibility in molding and are ideal for custom applications requiring manual layup techniques. Prepreg Kevlar features fibers pre-impregnated with resin, ensuring uniform resin distribution, enhanced strength, and consistent quality in high-performance composites. Choosing between dry and prepreg Kevlar depends on the specific manufacturing process, desired mechanical properties, and production volume.

Table of Comparison

| Feature | Dry Kevlar | Prepreg Kevlar |

|---|---|---|

| Material State | Uncoated, untreated fabric | Kevlar fibers pre-impregnated with resin |

| Processing | Requires manual resin application during layup | Ready to laminate, minimal handling required |

| Curing | Post-resin application curing needed | Curing integrated with prepreg resin system |

| Performance | Variable, depends on resin application quality | Consistent mechanical properties and resin distribution |

| Storage | No special requirements | Cold storage required to prevent premature curing |

| Cost | Generally lower material cost | Higher initial material cost, reduced labor |

| Application | Flexible for custom resin systems | Ideal for high-performance, precise manufacturing |

Understanding Kevlar: Properties and Uses

Dry Kevlar consists of unimpregnated fibers that provide flexibility and ease of handling, making it ideal for customized composite layups and protective gear manufacturing. Prepreg Kevlar features fibers pre-impregnated with proprietary resin systems, ensuring consistent resin distribution, enhanced structural integrity, and improved performance in aerospace and automotive applications. Both types leverage Kevlar's exceptional tensile strength, thermal stability, and impact resistance, optimizing lightweight yet durable solutions across industrial, military, and sporting goods sectors.

What is Dry Kevlar?

Dry Kevlar refers to unimpregnated Kevlar fibers that have not been combined with resins or adhesives, maintaining their original, flexible fabric form. These fibers are used in composite manufacturing where the resin matrix is applied later during processing, allowing for precise control over the resin content and material properties. Dry Kevlar offers advantages in customizing composite layups for applications requiring high strength-to-weight ratios and superior impact resistance.

What is Prepreg Kevlar?

Prepreg Kevlar consists of Kevlar fibers pre-impregnated with a resin matrix, providing enhanced structural integrity and simplified composite manufacturing. Unlike dry Kevlar, which requires resin infusion during the fabrication process, prepreg Kevlar ensures consistent resin distribution and improved mechanical properties. This material is widely used in aerospace, automotive, and protective gear industries for its superior strength-to-weight ratio and durability.

Manufacturing Processes: Dry vs Prepreg Kevlar

Dry Kevlar involves the infusion of resin into woven Kevlar fabric during the manufacturing process, allowing greater flexibility in resin choice and application methods. Prepreg Kevlar consists of Kevlar fibers pre-impregnated with resin and partially cured, ensuring uniform resin distribution and improved consistency during layup and curing. The manufacturing of dry Kevlar composites typically requires vacuum infusion or resin transfer molding, while prepreg Kevlar relies on autoclave curing for optimal fiber-resin bonding and mechanical performance.

Performance Comparison: Dry Kevlar vs Prepreg Kevlar

Dry Kevlar exhibits excellent impact resistance and flexibility due to its resin-free state, enabling superior conformability in complex composite shapes. Prepreg Kevlar, pre-impregnated with resin, offers enhanced uniformity, higher fiber volume fraction, and improved mechanical properties such as tensile strength and stiffness. The performance comparison reveals that while dry Kevlar caters to lightweight and adaptable applications, prepreg Kevlar ensures greater structural integrity and predictable performance in high-stress environments.

Cost Differences: Dry Kevlar vs Prepreg Kevlar

Dry Kevlar offers a more cost-effective solution due to lower material and processing expenses, making it ideal for large-scale applications requiring budget efficiency. Prepreg Kevlar involves higher costs stemming from its pre-impregnated resin state, specialized storage, and handling requirements that enhance performance but elevate price. Manufacturers must weigh the economic benefits of Dry Kevlar against the superior quality and processing advantages of Prepreg Kevlar when deciding based on project budgets.

Application Areas of Dry Kevlar

Dry Kevlar fibers are primarily utilized in applications requiring high tensile strength and flexibility, such as ballistic body armor, helmets, and protective clothing. These fibers enable customization in composite manufacturing, particularly in aerospace and automotive industries where precise fiber placement enhances impact resistance and weight reduction. The ability to mold dry Kevlar efficiently suits it for sports equipment and industrial gloves that demand durability and cut resistance.

Application Areas of Prepreg Kevlar

Prepreg Kevlar is extensively used in aerospace and automotive industries due to its superior consistency and enhanced mechanical properties, providing high strength-to-weight ratios essential for structural components. Its pre-impregnated resin matrix ensures optimal fiber alignment and uniform resin distribution, critical for advanced composite applications like helmets, body armor, and sports equipment. These features make prepreg Kevlar ideal for high-performance, safety-critical applications requiring precision and reliability.

Advantages and Disadvantages of Each Type

Dry Kevlar offers easier handling and lower cost, making it suitable for applications requiring flexibility and quick layup. Prepreg Kevlar provides superior fiber-resin bonding and consistent mechanical properties, ensuring enhanced strength and durability in high-performance composites. However, prepreg requires controlled storage and curing processes, increasing production complexity and cost compared to dry Kevlar materials.

Choosing the Right Kevlar Material for Your Project

Dry Kevlar offers flexibility and easier handling for custom laminating processes, making it ideal for projects requiring precise control over resin infusion and curing. Prepreg Kevlar, pre-impregnated with resin, ensures consistent resin distribution and superior mechanical properties, suitable for high-performance applications demanding repeatable strength and weight optimization. Selecting between dry and prepreg Kevlar depends on project-specific factors such as manufacturing capabilities, desired material performance, and budget constraints.

Dry Kevlar vs Prepreg Kevlar Infographic

materialdif.com

materialdif.com