Kevlar fabric is composed of woven or knitted Kevlar fibers, combining the strength and durability of individual fibers into a flexible, protective material. Kevlar fiber itself is a strong synthetic fiber known for its high tensile strength and resistance to heat, making it ideal for reinforcement in various applications. The fabric form enhances versatility for products like Kevlar pet gear, offering rugged protection while maintaining comfort and flexibility.

Table of Comparison

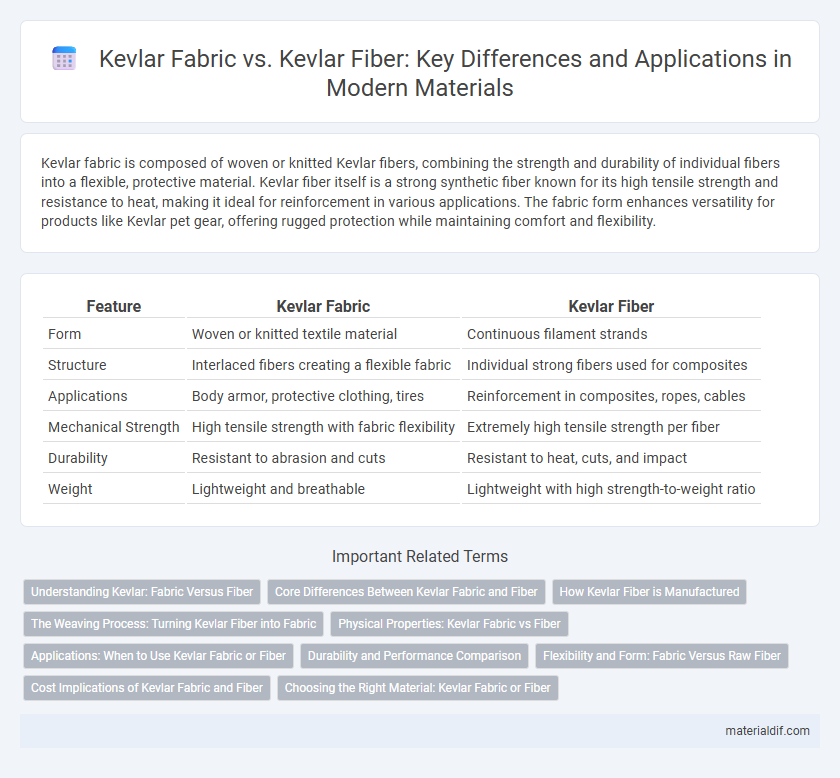

| Feature | Kevlar Fabric | Kevlar Fiber |

|---|---|---|

| Form | Woven or knitted textile material | Continuous filament strands |

| Structure | Interlaced fibers creating a flexible fabric | Individual strong fibers used for composites |

| Applications | Body armor, protective clothing, tires | Reinforcement in composites, ropes, cables |

| Mechanical Strength | High tensile strength with fabric flexibility | Extremely high tensile strength per fiber |

| Durability | Resistant to abrasion and cuts | Resistant to heat, cuts, and impact |

| Weight | Lightweight and breathable | Lightweight with high strength-to-weight ratio |

Understanding Kevlar: Fabric Versus Fiber

Kevlar fiber is a strong synthetic material composed of long chains of aromatic polyamide, known for its exceptional tensile strength and heat resistance. Kevlar fabric is created by weaving these fibers into a tightly knit textile, which enhances its durability, flexibility, and suitability for protective gear applications such as bulletproof vests and helmets. Understanding the difference between Kevlar fiber and fabric is crucial for selecting the right material based on strength, weight, and specific use cases in safety and industrial sectors.

Core Differences Between Kevlar Fabric and Fiber

Kevlar fiber consists of strong, synthetic aramid polymer threads that serve as the raw material for various applications, characterized by high tensile strength and thermal stability. Kevlar fabric is created by weaving or knitting these fibers into a structured textile, offering enhanced flexibility and durability for use in body armor, automotive components, and protective gear. The core difference lies in Kevlar fiber being the individual filament form, while Kevlar fabric represents a finished, engineered material optimized for practical performance and resilience.

How Kevlar Fiber is Manufactured

Kevlar fiber is manufactured through a process called polymerization, where monomers like para-aramid polyamide are combined to form long molecular chains, resulting in a strong and heat-resistant fiber. The polymer solution undergoes spinning, typically wet or dry-jet wet spinning, to extrude thin fibers that are then stretched to align the molecular chains and enhance tensile strength. These fibers form the foundation for Kevlar fabric, which is woven or knitted to create durable, lightweight materials used in ballistic protection, aerospace, and industrial applications.

The Weaving Process: Turning Kevlar Fiber into Fabric

Kevlar fiber undergoes a precise weaving process that transforms individual high-strength filaments into a durable Kevlar fabric known for its exceptional tensile strength and resistance to impact. The fibers are interlaced using tightly controlled loom settings to create a dense, flexible textile that retains Kevlar's inherent heat and cut-resistant properties. This weaving technique optimizes fiber alignment, enhancing the fabric's overall structural integrity and suitability for protective gear and industrial applications.

Physical Properties: Kevlar Fabric vs Fiber

Kevlar fiber exhibits exceptional tensile strength and high modulus, providing the foundational durability and lightweight characteristics vital for advanced composites. Kevlar fabric, composed of interwoven Kevlar fibers, enhances flexibility and impact resistance while maintaining the fiber's inherent high tensile strength and thermal stability. The fabric's layered structure offers superior resistance to abrasion and puncture, optimizing protection in ballistic and industrial applications.

Applications: When to Use Kevlar Fabric or Fiber

Kevlar fabric offers superior flexibility and abrasion resistance, making it ideal for protective clothing, body armor, and composite reinforcements where durability and comfort are crucial. Kevlar fiber is best suited for applications requiring high tensile strength and lightweight properties, such as ropes, cables, and ballistic fibers in aerospace and automotive parts. Selecting Kevlar fabric or fiber depends on the need for structural integrity versus adaptability in specific industrial and safety applications.

Durability and Performance Comparison

Kevlar fabric, composed of woven Kevlar fibers, offers enhanced durability and performance due to its structural integrity and resistance to abrasion, making it ideal for ballistic and protective applications. Kevlar fiber alone possesses exceptional tensile strength and flexibility but requires weaving into fabric form to maximize impact resistance and durability in practical use. The performance difference lies in the fabric's ability to distribute force across fibers, significantly improving protective qualities compared to individual Kevlar fibers.

Flexibility and Form: Fabric Versus Raw Fiber

Kevlar fabric offers enhanced flexibility and easier handling compared to raw Kevlar fiber, making it suitable for applications requiring molded shapes and wearable forms. While raw Kevlar fiber provides superior tensile strength and durability, it lacks the pliability needed for complex designs and comfort. The woven structure of Kevlar fabric distributes stress evenly, improving form retention and flexibility in protective gear and composite materials.

Cost Implications of Kevlar Fabric and Fiber

Kevlar fabric, made by weaving Kevlar fibers, generally incurs higher production costs due to its complex manufacturing process, which enhances durability and application versatility. Kevlar fiber alone is less expensive but requires further processing to achieve the tensile strength and flexibility needed for end-use products, impacting overall cost efficiency. Choosing between Kevlar fabric and fiber depends on balancing raw material expenses against performance requirements for specific industrial or protective gear applications.

Choosing the Right Material: Kevlar Fabric or Fiber

Selecting between Kevlar fabric and Kevlar fiber depends on the intended application, with Kevlar fiber providing high tensile strength and flexibility for composite materials and custom weaving. Kevlar fabric offers enhanced durability and impact resistance, commonly used in body armor, helmets, and protective gear due to its woven structure. Understanding the specific performance requirements ensures optimal protection and material efficiency.

Kevlar fabric vs Kevlar fiber Infographic

materialdif.com

materialdif.com