Kevlar sheets offer exceptional impact resistance and lightweight durability, making them ideal for protective pet gear that requires flexibility and toughness. Polycarbonate sheets provide strong, transparent protection with high shatter resistance, suitable for pet barriers and enclosures needing clear visibility. Choosing between Kevlar and polycarbonate depends on the priority of flexibility and stealth versus transparency and rigidity in pet safety applications.

Table of Comparison

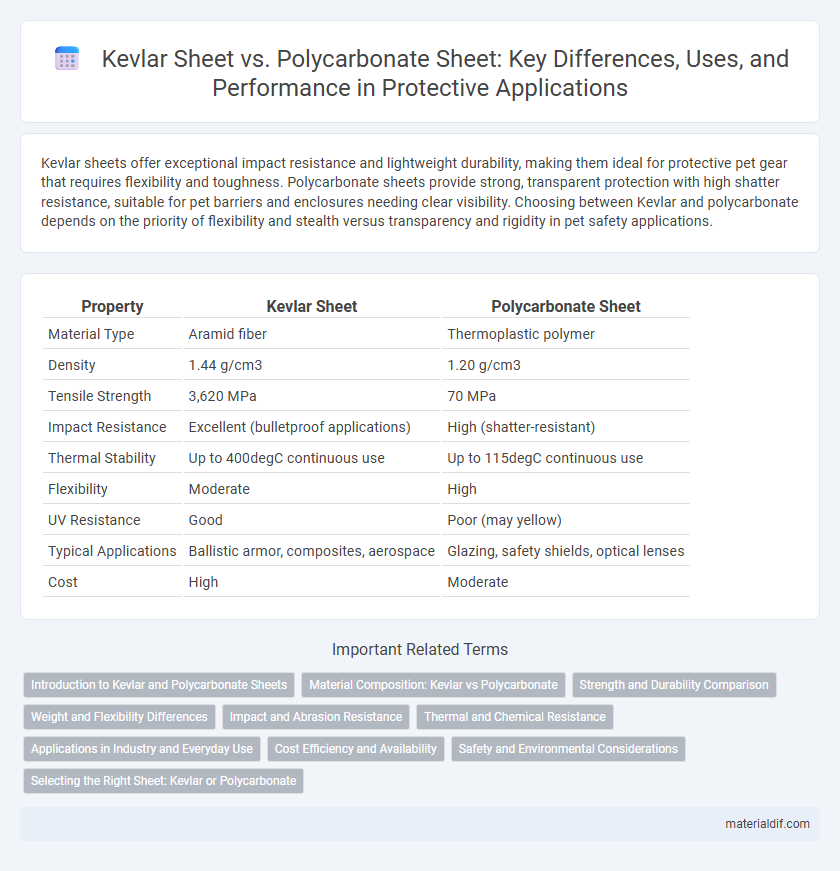

| Property | Kevlar Sheet | Polycarbonate Sheet |

|---|---|---|

| Material Type | Aramid fiber | Thermoplastic polymer |

| Density | 1.44 g/cm3 | 1.20 g/cm3 |

| Tensile Strength | 3,620 MPa | 70 MPa |

| Impact Resistance | Excellent (bulletproof applications) | High (shatter-resistant) |

| Thermal Stability | Up to 400degC continuous use | Up to 115degC continuous use |

| Flexibility | Moderate | High |

| UV Resistance | Good | Poor (may yellow) |

| Typical Applications | Ballistic armor, composites, aerospace | Glazing, safety shields, optical lenses |

| Cost | High | Moderate |

Introduction to Kevlar and Polycarbonate Sheets

Kevlar sheets are composed of aramid fibers known for their high tensile strength and exceptional resistance to impact, heat, and abrasion, making them ideal for protective applications. Polycarbonate sheets are lightweight, transparent thermoplastics offering excellent impact resistance and optical clarity, widely used in safety glazing and industrial components. Comparing both materials highlights Kevlar's superior durability and ballistic protection against polycarbonate's flexibility and visual transparency.

Material Composition: Kevlar vs Polycarbonate

Kevlar sheets are composed of aramid fibers known for exceptional tensile strength and heat resistance, making them ideal for ballistic and protective applications. Polycarbonate sheets consist of a thermoplastic polymer valued for impact resistance, clarity, and lightweight properties, often used in glazing and safety shields. The molecular structure of Kevlar provides superior durability under extreme conditions, while polycarbonate offers flexibility and transparency for general safety uses.

Strength and Durability Comparison

Kevlar sheets exhibit exceptional tensile strength and impact resistance, making them highly durable under extreme stress and resistant to wear, while polycarbonate sheets offer superior flexibility and high impact resistance but lower tensile strength compared to Kevlar. Kevlar's molecular structure provides enhanced resistance to abrasion and puncture, ensuring long-lasting performance in demanding environments. Polycarbonate sheets can absorb significant energy without cracking, but Kevlar's durability in high-stress applications, such as ballistic and protective gear, outperforms polycarbonate in strength and longevity.

Weight and Flexibility Differences

Kevlar sheets are significantly lighter than polycarbonate sheets, offering high strength-to-weight ratio crucial for applications requiring minimal weight without compromising durability. Kevlar also exhibits greater flexibility and impact resistance, making it ideal for protective gear and flexible armor solutions. Conversely, polycarbonate sheets are stiffer and heavier but provide excellent transparency and rigidity, often used in applications where visibility and hardness are prioritized over flexibility.

Impact and Abrasion Resistance

Kevlar sheets exhibit superior impact resistance due to their high tensile strength and energy absorption capabilities, making them ideal for ballistic and protective applications. Their abrasion resistance surpasses polycarbonate sheets, as the tightly woven Kevlar fibers maintain integrity under repeated friction and wear. Polycarbonate sheets, while tough and flexible, tend to scratch and degrade faster under harsh abrasive conditions compared to Kevlar's robust performance.

Thermal and Chemical Resistance

Kevlar sheets exhibit superior thermal resistance, maintaining structural integrity at temperatures up to 450degC, compared to polycarbonate sheets that typically soften around 147degC. Chemically, Kevlar offers excellent resistance to solvents, acids, and bases, making it ideal for harsh industrial environments, whereas polycarbonate sheets are more prone to degradation when exposed to certain chemicals like acetones and alkaline solutions. This makes Kevlar sheets the preferred choice for applications demanding high thermal stability and robust chemical resistance.

Applications in Industry and Everyday Use

Kevlar sheets offer exceptional tensile strength and heat resistance, making them ideal for bulletproof vests, aerospace components, and automotive body panels where durability and safety are critical. Polycarbonate sheets provide superior impact resistance and optical clarity, widely used in eyewear lenses, greenhouse panels, and protective barriers in public spaces. Industries prioritize Kevlar for high-stress, protective applications, while polycarbonate is favored for lightweight, transparent, and flexible solutions in everyday use.

Cost Efficiency and Availability

Kevlar sheets offer superior cost efficiency in high-impact protection applications due to their exceptional strength-to-weight ratio, reducing material volume requirements. Polycarbonate sheets provide greater availability and lower upfront costs, making them suitable for general use and short-term projects. The choice depends on balancing long-term durability and upfront budget constraints.

Safety and Environmental Considerations

Kevlar sheets offer superior ballistic resistance and impact protection, making them ideal for safety-critical applications such as body armor and protective gear, while their lightweight and high tensile strength contribute to enhanced user comfort and mobility. Polycarbonate sheets provide excellent impact resistance and clarity but are more prone to scratching and UV degradation, which may compromise safety over time in extreme conditions. From an environmental perspective, Kevlar production involves more energy-intensive processes and challenges in recycling, whereas polycarbonate sheets are more recyclable, though both materials pose environmental concerns related to chemical usage and waste management.

Selecting the Right Sheet: Kevlar or Polycarbonate

Kevlar sheets offer exceptional tensile strength and impact resistance, making them ideal for applications requiring superior durability and lightweight protection. Polycarbonate sheets provide excellent optical clarity and high impact resistance, suitable for environments needing transparency and shatterproof qualities. Selecting between Kevlar and polycarbonate sheets depends on whether strength-to-weight ratio or visual clarity is the priority.

Kevlar Sheet vs Polycarbonate Sheet Infographic

materialdif.com

materialdif.com