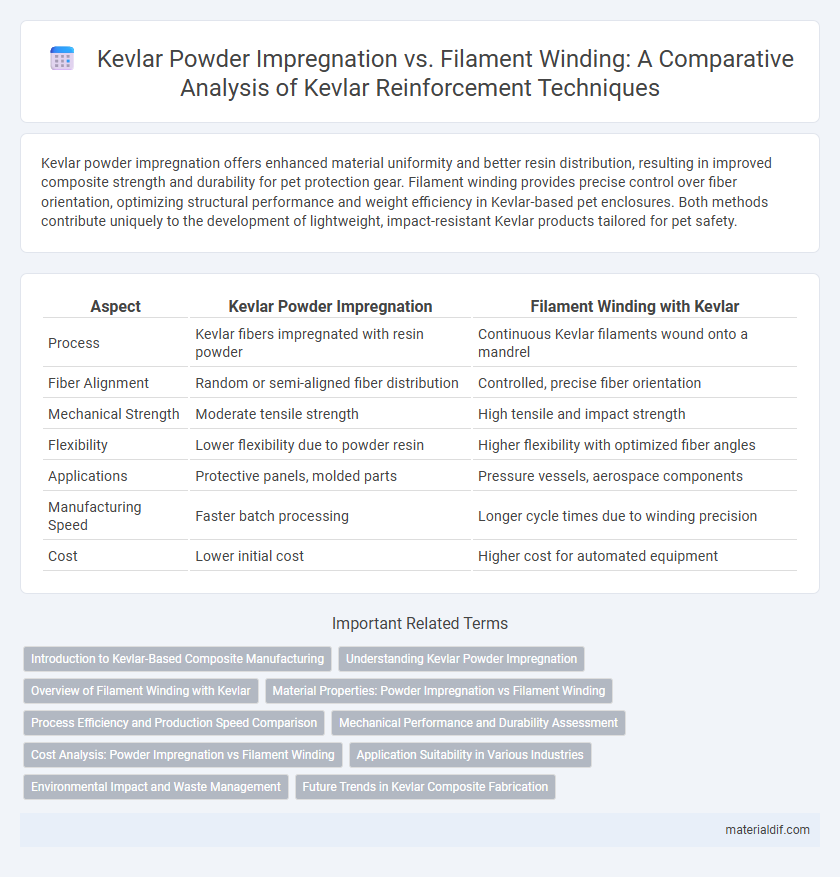

Kevlar powder impregnation offers enhanced material uniformity and better resin distribution, resulting in improved composite strength and durability for pet protection gear. Filament winding provides precise control over fiber orientation, optimizing structural performance and weight efficiency in Kevlar-based pet enclosures. Both methods contribute uniquely to the development of lightweight, impact-resistant Kevlar products tailored for pet safety.

Table of Comparison

| Aspect | Kevlar Powder Impregnation | Filament Winding with Kevlar |

|---|---|---|

| Process | Kevlar fibers impregnated with resin powder | Continuous Kevlar filaments wound onto a mandrel |

| Fiber Alignment | Random or semi-aligned fiber distribution | Controlled, precise fiber orientation |

| Mechanical Strength | Moderate tensile strength | High tensile and impact strength |

| Flexibility | Lower flexibility due to powder resin | Higher flexibility with optimized fiber angles |

| Applications | Protective panels, molded parts | Pressure vessels, aerospace components |

| Manufacturing Speed | Faster batch processing | Longer cycle times due to winding precision |

| Cost | Lower initial cost | Higher cost for automated equipment |

Introduction to Kevlar-Based Composite Manufacturing

Kevlar powder impregnation involves embedding fine Kevlar particles into a resin matrix to enhance composite strength and impact resistance, offering uniform material distribution and tailored mechanical properties. Filament winding uses continuous Kevlar fibers wound under tension around a mandrel, creating high-strength, lightweight composite structures with superior load-bearing capabilities. Both methods are essential in Kevlar-based composite manufacturing, with powder impregnation suited for complex shapes and filament winding ideal for cylindrical or tubular components.

Understanding Kevlar Powder Impregnation

Kevlar powder impregnation involves embedding Kevlar fibers with a powdered resin, enhancing fiber-matrix adhesion and improving mechanical properties such as tensile strength and impact resistance. This method ensures uniform resin distribution, leading to consistent performance in composite materials. In contrast, filament winding uses continuous Kevlar strands wound under tension with resin application, offering different structural benefits but less control over uniform resin impregnation compared to powder impregnation.

Overview of Filament Winding with Kevlar

Filament winding with Kevlar involves precisely winding continuous Kevlar fibers onto a rotating mandrel to create high-strength composite structures with excellent tensile properties and lightweight characteristics. This process ensures uniform resin impregnation and fiber alignment, resulting in superior impact resistance and dimensional stability compared to Kevlar powder impregnation techniques. Widely used in aerospace, automotive, and sports equipment, Kevlar filament winding optimizes mechanical performance and durability in critical applications.

Material Properties: Powder Impregnation vs Filament Winding

Kevlar powder impregnation enhances material uniformity and resin distribution, resulting in improved impact resistance and consistent tensile strength across composites. Filament winding aligns Kevlar fibers precisely along load paths, maximizing fiber volume fraction and delivering superior anisotropic mechanical properties such as high stiffness and directional strength. The choice between powder impregnation and filament winding significantly influences composite density, fiber-matrix adhesion, and overall performance tailored to specific structural applications.

Process Efficiency and Production Speed Comparison

Kevlar powder impregnation offers uniform resin distribution, enhancing composite material consistency but involves longer curing times that can reduce overall production speed. Filament winding enables rapid layer deposition and continuous fiber alignment, significantly increasing process efficiency and throughput in manufacturing cylindrical Kevlar components. Comparing both, filament winding generally achieves faster production cycles, while powder impregnation provides superior material uniformity at a slower pace.

Mechanical Performance and Durability Assessment

Kevlar powder impregnation enhances matrix adhesion, resulting in improved tensile strength and impact resistance compared to filament winding. Filament winding offers superior fiber alignment, optimizing load distribution and fatigue life under cyclical stress. Durability assessments show powder-impregnated Kevlar composites exhibit better resistance to environmental degradation, while filament-wound structures excel in maintaining mechanical integrity under repeated mechanical loading.

Cost Analysis: Powder Impregnation vs Filament Winding

Kevlar powder impregnation offers a cost-effective solution by reducing raw material waste and enabling simplified equipment compared to filament winding, which often involves higher labor and machine expenses due to its complexity. Filament winding, while delivering superior fiber alignment and structural performance, incurs increased operational costs from specialized tooling and slower production cycles. Evaluating the cost analysis reveals that powder impregnation is advantageous for large-scale, less intricate components, whereas filament winding justifies its higher costs in applications demanding optimal mechanical properties.

Application Suitability in Various Industries

Kevlar powder impregnation enhances composite material hardness and uniformity, making it ideal for ballistic armor and protective coatings in aerospace and defense industries. Filament winding offers superior strength-to-weight ratios and precise fiber alignment, preferred for pressure vessels and aerospace structural components. Both techniques provide industry-specific advantages: impregnation suits applications requiring consistent surface properties, while filament winding excels in manufacturing high-performance mechanical parts.

Environmental Impact and Waste Management

Kevlar powder impregnation generates significantly less processing waste compared to filament winding, reducing environmental pollutants and lowering the need for extensive waste management systems. Filament winding often results in scrap fibers and excess resin, which require careful disposal or recycling to minimize environmental harm. Powder impregnation techniques enhance material utilization efficiency, contributing to a smaller carbon footprint in composite manufacturing.

Future Trends in Kevlar Composite Fabrication

Kevlar powder impregnation offers precise resin distribution and enhanced interfacial bonding, improving composite strength and durability for advanced aerospace and automotive applications. Filament winding remains advantageous for producing large, structurally demanding components with optimized fiber orientation and minimal waste. Future trends indicate hybrid fabrication techniques combining powder impregnation's material uniformity with filament winding's structural efficiency, driving innovation in lightweight, high-performance Kevlar composites.

Kevlar powder impregnation vs Filament winding Infographic

materialdif.com

materialdif.com