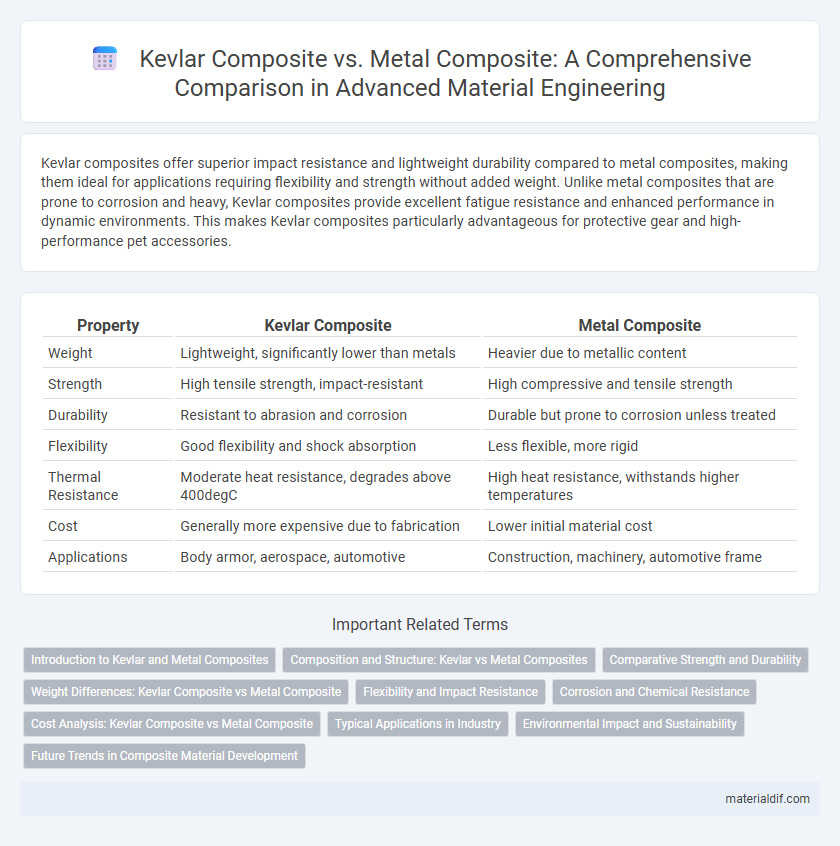

Kevlar composites offer superior impact resistance and lightweight durability compared to metal composites, making them ideal for applications requiring flexibility and strength without added weight. Unlike metal composites that are prone to corrosion and heavy, Kevlar composites provide excellent fatigue resistance and enhanced performance in dynamic environments. This makes Kevlar composites particularly advantageous for protective gear and high-performance pet accessories.

Table of Comparison

| Property | Kevlar Composite | Metal Composite |

|---|---|---|

| Weight | Lightweight, significantly lower than metals | Heavier due to metallic content |

| Strength | High tensile strength, impact-resistant | High compressive and tensile strength |

| Durability | Resistant to abrasion and corrosion | Durable but prone to corrosion unless treated |

| Flexibility | Good flexibility and shock absorption | Less flexible, more rigid |

| Thermal Resistance | Moderate heat resistance, degrades above 400degC | High heat resistance, withstands higher temperatures |

| Cost | Generally more expensive due to fabrication | Lower initial material cost |

| Applications | Body armor, aerospace, automotive | Construction, machinery, automotive frame |

Introduction to Kevlar and Metal Composites

Kevlar composites are composed of aramid fibers known for their exceptional tensile strength-to-weight ratio, making them ideal for lightweight, high-performance applications such as aerospace, military armor, and automotive components. Metal composites typically combine metal matrices like aluminum or titanium with reinforcing fibers or particles to enhance strength, stiffness, and thermal resistance while maintaining durability under extreme conditions. Kevlar composites outperform metal composites in impact resistance and flexibility, but metal composites offer superior thermal stability and electrical conductivity for specialized engineering uses.

Composition and Structure: Kevlar vs Metal Composites

Kevlar composites consist of aramid fibers embedded in a polymer matrix, offering high tensile strength and exceptional impact resistance with low weight, while metal composites combine metal matrices like aluminum or titanium with reinforcing fibers or particles to enhance hardness and thermal conductivity. The molecular structure of Kevlar features long polymer chains aligned in a crystalline arrangement, providing excellent flexibility and energy absorption, contrasting with metal composites that rely on metallic bonding and microstructural grain boundaries for strength and ductility. Kevlar composites excel in applications requiring lightweight durability and ballistic protection, whereas metal composites are preferred for high-temperature environments and structural load-bearing demanding toughness.

Comparative Strength and Durability

Kevlar composites exhibit superior tensile strength and impact resistance compared to metal composites, making them ideal for applications requiring lightweight durability. Their high strength-to-weight ratio allows for enhanced structural integrity without the added mass, unlike traditional metal composites that often suffer from brittleness and corrosion over time. Kevlar's resistance to fatigue and extreme environmental conditions further extends its lifespan beyond most metal composites, offering prolonged performance in demanding settings.

Weight Differences: Kevlar Composite vs Metal Composite

Kevlar composites offer significant weight advantages over metal composites, typically reducing overall material weight by up to 40-60%. This reduction stems from Kevlar's high strength-to-weight ratio, making it ideal for applications where minimizing mass is critical, such as aerospace and automotive industries. Metal composites, while durable, often add substantial weight, impacting fuel efficiency and performance compared to Kevlar-based alternatives.

Flexibility and Impact Resistance

Kevlar composite offers superior flexibility compared to metal composites due to its lightweight and fiber-reinforced structure, enabling better energy absorption and deformation under stress without cracking. Its high tensile strength and exceptional impact resistance allow Kevlar composites to dissipate impact forces effectively, reducing the risk of structural failure in applications like body armor and aerospace components. Metal composites, while strong, tend to be more rigid and prone to brittle fractures under high impact, making Kevlar composites the preferred choice in scenarios demanding a balance of flexibility and impact resilience.

Corrosion and Chemical Resistance

Kevlar composites exhibit superior corrosion resistance compared to metal composites due to their inert polymer matrix, which resists oxidation and chemical degradation in harsh environments. Unlike metals, Kevlar does not rust or require protective coatings, significantly reducing maintenance costs and extending service life in applications exposed to water, acids, or alkalis. This chemical stability makes Kevlar composites ideal for marine, chemical processing, and aerospace industries where durability against corrosive agents is critical.

Cost Analysis: Kevlar Composite vs Metal Composite

Kevlar composites generally offer a lower overall lifecycle cost compared to metal composites due to reduced maintenance and longer durability despite higher initial material costs. Metal composites often incur increased expenses from corrosion resistance treatments and heavier weight leading to higher transportation and handling costs. The cost-efficiency of Kevlar composites grows in applications prioritizing weight savings and impact resistance, making them a preferred choice over metals in aerospace and automotive industries.

Typical Applications in Industry

Kevlar composites are widely used in aerospace, automotive, and ballistic protection industries due to their high strength-to-weight ratio, impact resistance, and corrosion resistance. Metal composites, often utilized in construction and heavy machinery, offer superior hardness and thermal conductivity but are generally heavier and less flexible than Kevlar composites. The aerospace sector favors Kevlar composites for lightweight structural components, while metal composites are preferred in applications requiring extreme durability and load-bearing capacity.

Environmental Impact and Sustainability

Kevlar composite materials exhibit significantly lower environmental impact compared to metal composites due to their lightweight nature, which reduces energy consumption during transportation and use. Kevlar's high strength-to-weight ratio enables longer product lifespans and decreases the need for frequent replacements, contributing to sustainability. Furthermore, Kevlar composites often require less energy-intensive manufacturing processes and generate fewer greenhouse gas emissions than traditional metal composites.

Future Trends in Composite Material Development

Kevlar composites exhibit superior strength-to-weight ratios and enhanced impact resistance compared to traditional metal composites, driving increased adoption in aerospace and automotive industries. Future trends emphasize the integration of Kevlar with advanced nanomaterials such as graphene to further improve durability and thermal stability. Research is also focusing on sustainable manufacturing processes and recycling methods to address environmental concerns while maintaining performance standards.

Kevlar composite vs Metal composite Infographic

materialdif.com

materialdif.com