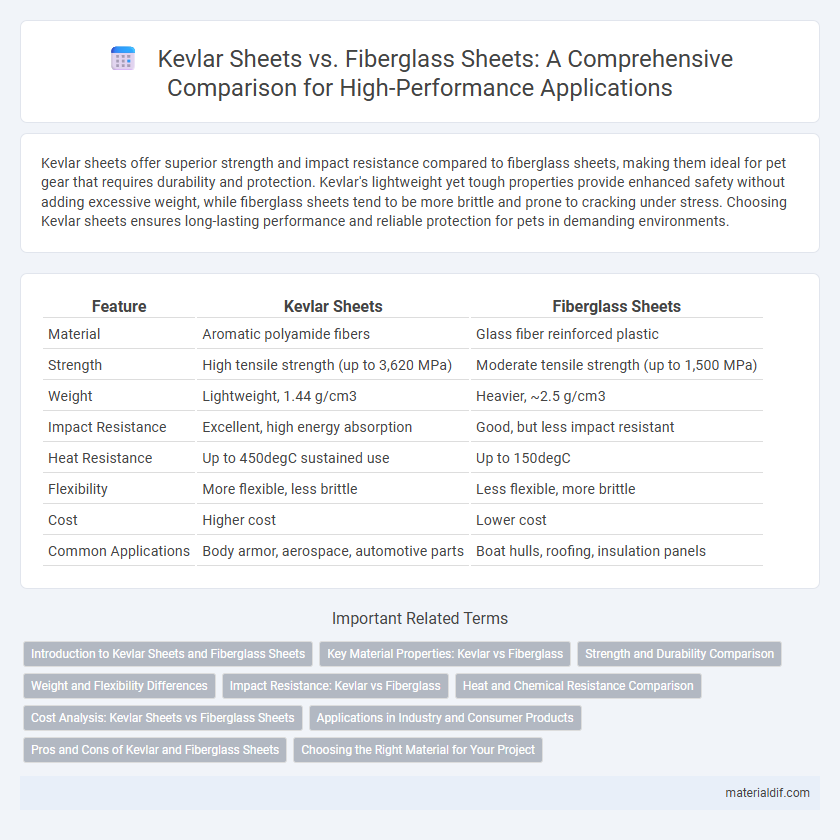

Kevlar sheets offer superior strength and impact resistance compared to fiberglass sheets, making them ideal for pet gear that requires durability and protection. Kevlar's lightweight yet tough properties provide enhanced safety without adding excessive weight, while fiberglass sheets tend to be more brittle and prone to cracking under stress. Choosing Kevlar sheets ensures long-lasting performance and reliable protection for pets in demanding environments.

Table of Comparison

| Feature | Kevlar Sheets | Fiberglass Sheets |

|---|---|---|

| Material | Aromatic polyamide fibers | Glass fiber reinforced plastic |

| Strength | High tensile strength (up to 3,620 MPa) | Moderate tensile strength (up to 1,500 MPa) |

| Weight | Lightweight, 1.44 g/cm3 | Heavier, ~2.5 g/cm3 |

| Impact Resistance | Excellent, high energy absorption | Good, but less impact resistant |

| Heat Resistance | Up to 450degC sustained use | Up to 150degC |

| Flexibility | More flexible, less brittle | Less flexible, more brittle |

| Cost | Higher cost | Lower cost |

| Common Applications | Body armor, aerospace, automotive parts | Boat hulls, roofing, insulation panels |

Introduction to Kevlar Sheets and Fiberglass Sheets

Kevlar sheets are composed of para-aramid synthetic fibers known for exceptional tensile strength, lightweight properties, and high resistance to impact and heat. Fiberglass sheets consist of fine glass fibers woven into a rigid matrix, offering strong durability, corrosion resistance, and cost-effective reinforcement. Both materials serve critical roles in industrial applications, with Kevlar sheets favored for high-performance impact resistance and fiberglass sheets commonly used for structural support and insulation.

Key Material Properties: Kevlar vs Fiberglass

Kevlar sheets exhibit exceptional tensile strength and superior impact resistance compared to fiberglass sheets, making them ideal for high-stress applications. The molecular structure of Kevlar fibers results in higher toughness and better energy absorption, whereas fiberglass offers excellent compression strength and chemical resistance at a lower cost. Kevlar's lightweight nature combined with its thermal stability provides performance advantages in demanding environments over the more brittle and heavier fiberglass sheets.

Strength and Durability Comparison

Kevlar sheets exhibit superior tensile strength and impact resistance compared to fiberglass sheets, making them ideal for high-stress applications requiring exceptional durability. Kevlar's molecular structure provides excellent resistance to fatigue, abrasion, and heat, outperforming fiberglass in maintaining integrity under prolonged stress. While fiberglass sheets offer good rigidity and cost-effectiveness, Kevlar sheets deliver enhanced longevity and reliability in demanding environments.

Weight and Flexibility Differences

Kevlar sheets are significantly lighter than fiberglass sheets, offering a weight advantage essential for applications requiring high strength-to-weight ratios. Kevlar also provides superior flexibility, allowing it to bend without compromising structural integrity, whereas fiberglass tends to be more rigid and brittle. This combination of low weight and enhanced flexibility makes Kevlar sheets ideal for protective gear and aerospace components where durability and maneuverability are critical.

Impact Resistance: Kevlar vs Fiberglass

Kevlar sheets exhibit superior impact resistance compared to fiberglass sheets, thanks to Kevlar's exceptional tensile strength and energy absorption capabilities. Kevlar's molecular structure allows it to dissipate force more effectively, making it highly resistant to cracks and fractures under high-velocity impacts. Fiberglass sheets, while strong, tend to be more brittle and prone to shattering upon significant impact, limiting their use in protective applications.

Heat and Chemical Resistance Comparison

Kevlar sheets exhibit superior heat resistance, maintaining structural integrity at temperatures up to 450degC, compared to fiberglass sheets which typically withstand heat up to 250degC. Chemically, Kevlar demonstrates exceptional resistance to organic solvents and acids, whereas fiberglass is more susceptible to chemical degradation when exposed to strong alkalis and acidic environments. This makes Kevlar sheets a preferred choice in high-temperature and chemically aggressive applications requiring reliable durability.

Cost Analysis: Kevlar Sheets vs Fiberglass Sheets

Kevlar sheets typically cost significantly more than fiberglass sheets due to their superior tensile strength and impact resistance, which are essential for high-performance applications. Fiberglass sheets offer a more budget-friendly option with adequate durability for general use, making them preferable for cost-sensitive projects. The price difference often reflects the material properties and manufacturing complexities associated with Kevlar's advanced aramid fibers compared to the more common glass fibers in fiberglass.

Applications in Industry and Consumer Products

Kevlar sheets offer superior tensile strength and impact resistance, making them ideal for ballistic protection, aerospace components, and protective sporting gear. Fiberglass sheets are preferred in automotive body panels, boat hulls, and construction materials due to their cost-effectiveness and excellent corrosion resistance. Industries select Kevlar for high-stress applications requiring lightweight durability, while fiberglass suits applications needing versatile, lower-cost reinforcement.

Pros and Cons of Kevlar and Fiberglass Sheets

Kevlar sheets offer superior tensile strength and impact resistance compared to fiberglass sheets, making them ideal for applications requiring high durability and lightweight protection. Fiberglass sheets provide excellent corrosion resistance and cost-effectiveness but lack the flexibility and strength-to-weight ratio of Kevlar. While Kevlar excels in toughness and energy absorption, fiberglass sheets are more suitable for general-purpose reinforcement due to their affordability and ease of fabrication.

Choosing the Right Material for Your Project

Kevlar sheets offer superior tensile strength and impact resistance compared to fiberglass sheets, making them ideal for applications requiring high durability and lightweight protection. Fiberglass sheets are more cost-effective and provide excellent thermal insulation and corrosion resistance, suitable for budget-conscious projects with moderate strength needs. Selecting between Kevlar and fiberglass sheets depends on the project's performance requirements, budget constraints, and environmental exposure.

Kevlar Sheets vs Fiberglass Sheets Infographic

materialdif.com

materialdif.com