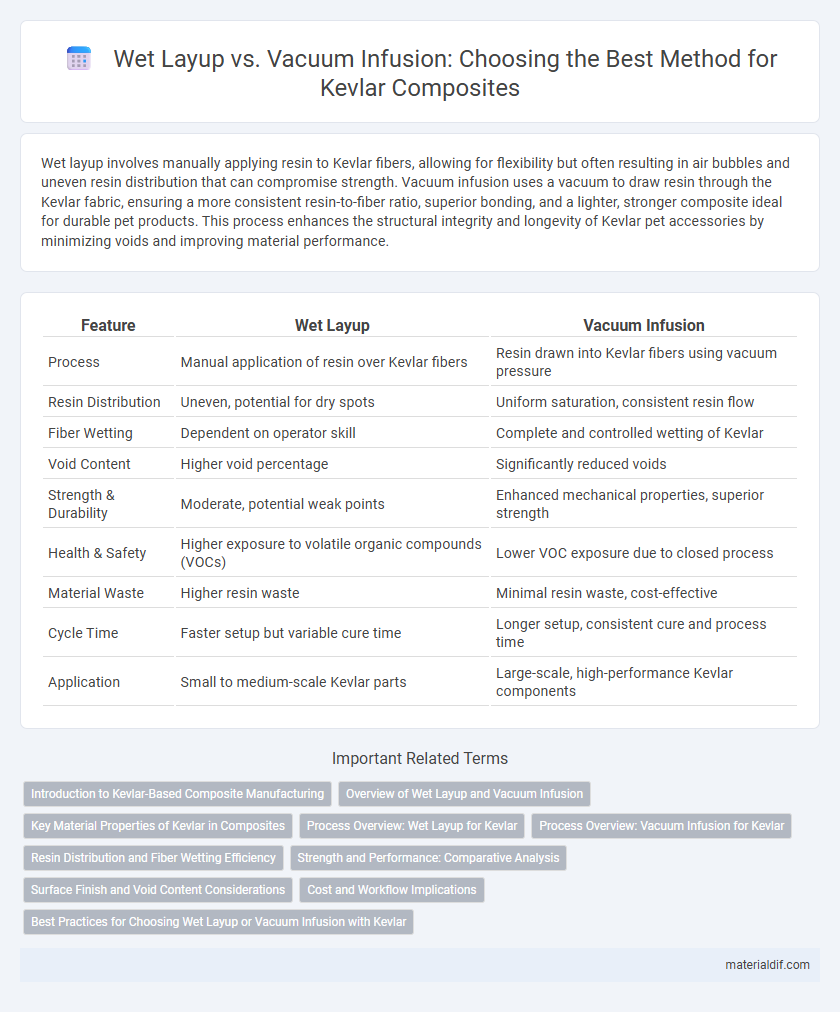

Wet layup involves manually applying resin to Kevlar fibers, allowing for flexibility but often resulting in air bubbles and uneven resin distribution that can compromise strength. Vacuum infusion uses a vacuum to draw resin through the Kevlar fabric, ensuring a more consistent resin-to-fiber ratio, superior bonding, and a lighter, stronger composite ideal for durable pet products. This process enhances the structural integrity and longevity of Kevlar pet accessories by minimizing voids and improving material performance.

Table of Comparison

| Feature | Wet Layup | Vacuum Infusion |

|---|---|---|

| Process | Manual application of resin over Kevlar fibers | Resin drawn into Kevlar fibers using vacuum pressure |

| Resin Distribution | Uneven, potential for dry spots | Uniform saturation, consistent resin flow |

| Fiber Wetting | Dependent on operator skill | Complete and controlled wetting of Kevlar |

| Void Content | Higher void percentage | Significantly reduced voids |

| Strength & Durability | Moderate, potential weak points | Enhanced mechanical properties, superior strength |

| Health & Safety | Higher exposure to volatile organic compounds (VOCs) | Lower VOC exposure due to closed process |

| Material Waste | Higher resin waste | Minimal resin waste, cost-effective |

| Cycle Time | Faster setup but variable cure time | Longer setup, consistent cure and process time |

| Application | Small to medium-scale Kevlar parts | Large-scale, high-performance Kevlar components |

Introduction to Kevlar-Based Composite Manufacturing

Kevlar-based composite manufacturing primarily utilizes wet layup and vacuum infusion techniques to optimize strength-to-weight ratios in aerospace and automotive applications. Wet layup involves manually saturating Kevlar fibers with resin, providing flexibility for complex shapes but often resulting in higher void content. Vacuum infusion uses vacuum pressure to draw resin through the Kevlar fabric, enhancing fiber-to-resin bonding and producing composites with superior mechanical properties and reduced resin waste.

Overview of Wet Layup and Vacuum Infusion

Wet layup involves manually applying resin directly onto Kevlar fabric layers, allowing for flexible mold shapes but often resulting in higher resin use and potential air entrapment. Vacuum infusion uses a sealed mold and vacuum pressure to draw resin through the Kevlar layers, ensuring even saturation, reduced resin weight, and improved fiber-to-resin ratios. This method typically produces stronger, lighter Kevlar composites with enhanced structural integrity compared to wet layup.

Key Material Properties of Kevlar in Composites

Kevlar exhibits exceptional tensile strength and impact resistance, making it ideal for composite materials in both wet layup and vacuum infusion processes. Wet layup involves manually saturating Kevlar fibers with resin, which may result in lower fiber-to-resin ratios and potential voids, whereas vacuum infusion ensures even resin distribution, maximizing Kevlar's strength and stiffness. The high toughness and low density of Kevlar enhance composite durability and weight reduction, critical factors influenced by the chosen manufacturing method.

Process Overview: Wet Layup for Kevlar

Wet layup for Kevlar involves manually placing Kevlar fabric layers into a mold and saturating them with resin using brushes or rollers, allowing precise control over fiber placement and resin distribution. This hands-on process requires careful attention to avoid air entrapment and ensure thorough impregnation of the Kevlar fibers, which is crucial for maximizing the composite's strength and impact resistance. The wet layup method is favored in applications where custom shapes and moderate production volumes necessitate flexibility and detailed workmanship.

Process Overview: Vacuum Infusion for Kevlar

Vacuum infusion for Kevlar involves placing dry Kevlar fabric in a mold followed by sealing it with a vacuum bag and drawing resin into the fibers using vacuum pressure. This process ensures complete resin saturation, minimizes air entrapment, and results in a lightweight, high-strength composite. Vacuum infusion offers superior control over resin distribution compared to wet layup, enhancing mechanical properties and overall durability of Kevlar composites.

Resin Distribution and Fiber Wetting Efficiency

Vacuum infusion offers superior resin distribution and fiber wetting efficiency compared to wet layup, as the controlled vacuum pressure ensures complete saturation of Kevlar fibers without air entrapment. In wet layup, inconsistent resin application often leads to dry spots and resin-rich areas, compromising the structural integrity and performance of Kevlar composites. Optimized resin flow in vacuum infusion enhances bonding and mechanical properties, making it the preferred method for high-performance Kevlar composite manufacturing.

Strength and Performance: Comparative Analysis

Wet layup offers strong mechanical bonding in Kevlar composites but may introduce air voids that reduce overall strength and performance. Vacuum infusion ensures superior fiber-to-resin ratio and eliminates air pockets, resulting in higher tensile strength and enhanced impact resistance for Kevlar laminates. Performance testing shows vacuum-infused Kevlar parts consistently outperform wet layup counterparts in structural integrity and fatigue life.

Surface Finish and Void Content Considerations

Wet layup often results in higher void content and a less uniform surface finish compared to vacuum infusion, due to manual resin application and air entrapment. Vacuum infusion enhances surface finish by providing a more consistent resin flow and significantly reduces voids through controlled pressure, improving the overall integrity of Kevlar composites. These factors make vacuum infusion the preferred method for achieving superior mechanical properties and surface aesthetics in Kevlar components.

Cost and Workflow Implications

Wet layup offers lower upfront costs and simpler workflow suitable for small-scale Kevlar composite manufacturing, relying on manual resin application and open molds. Vacuum infusion demands higher initial investment in vacuum equipment and consumables but provides improved resin control, reduced material waste, and consistent quality, enhancing scalability for complex Kevlar parts. Workflow efficiency in vacuum infusion results from automation and reduced labor intensity compared to the labor-intensive wet layup process.

Best Practices for Choosing Wet Layup or Vacuum Infusion with Kevlar

Wet layup with Kevlar offers greater control for complex shapes and smaller projects but requires meticulous hand application to avoid air entrapment and achieve uniform resin distribution. Vacuum infusion enhances fiber-to-resin ratio and structural integrity by applying consistent pressure, making it ideal for large-scale or high-performance Kevlar composites demanding superior strength and weight optimization. Selecting between wet layup and vacuum infusion depends on project size, complexity, desired mechanical properties, and production volume to ensure optimal Kevlar reinforcement and resin bonding.

Wet layup vs Vacuum infusion Infographic

materialdif.com

materialdif.com