Kevlar resin infusion offers superior strength and durability compared to Kevlar wet layup by ensuring even resin distribution and reducing voids within the composite. Resin infusion enhances bonding and structural integrity, making it ideal for high-performance Kevlar pet applications. Wet layup, while simpler and faster, may result in inconsistent resin coverage, leading to weaker and less reliable Kevlar composites.

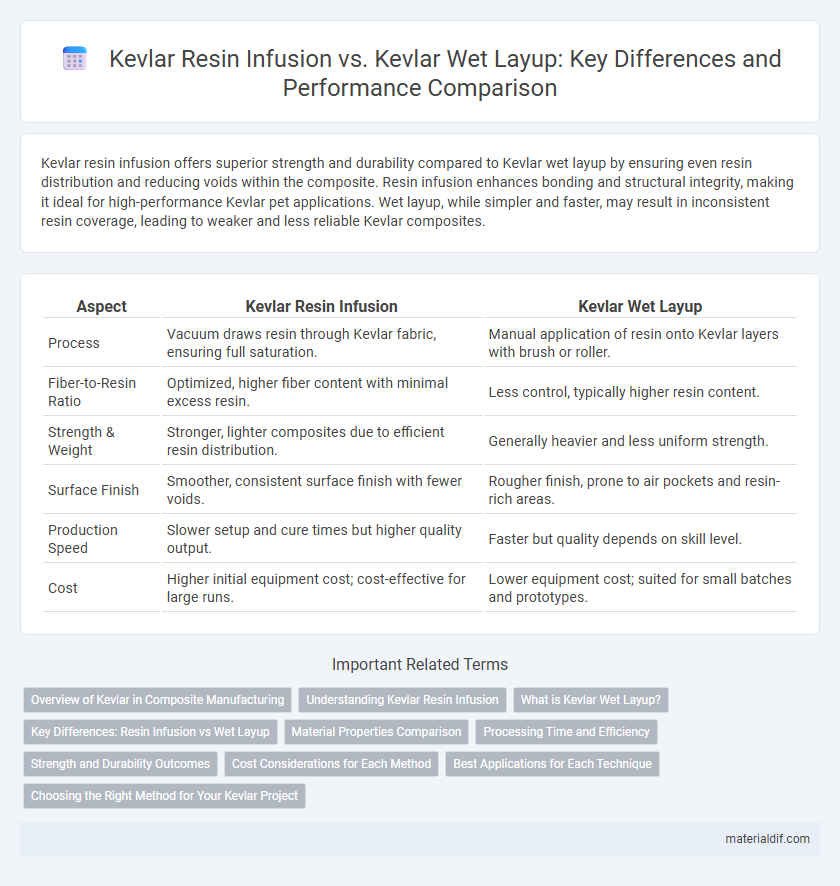

Table of Comparison

| Aspect | Kevlar Resin Infusion | Kevlar Wet Layup |

|---|---|---|

| Process | Vacuum draws resin through Kevlar fabric, ensuring full saturation. | Manual application of resin onto Kevlar layers with brush or roller. |

| Fiber-to-Resin Ratio | Optimized, higher fiber content with minimal excess resin. | Less control, typically higher resin content. |

| Strength & Weight | Stronger, lighter composites due to efficient resin distribution. | Generally heavier and less uniform strength. |

| Surface Finish | Smoother, consistent surface finish with fewer voids. | Rougher finish, prone to air pockets and resin-rich areas. |

| Production Speed | Slower setup and cure times but higher quality output. | Faster but quality depends on skill level. |

| Cost | Higher initial equipment cost; cost-effective for large runs. | Lower equipment cost; suited for small batches and prototypes. |

Overview of Kevlar in Composite Manufacturing

Kevlar resin infusion offers enhanced fiber consolidation and superior resin-to-fiber ratio compared to Kevlar wet layup, resulting in composites with higher strength-to-weight performance and improved dimensional stability. Kevlar wet layup remains a popular method for simpler or low-volume production but often leads to increased resin content and higher void levels, affecting mechanical properties. In composite manufacturing, choosing Kevlar resin infusion optimizes the material's ballistic resistance and impact toughness while ensuring consistent quality in advanced aerospace and protective applications.

Understanding Kevlar Resin Infusion

Kevlar resin infusion involves impregnating Kevlar fibers with resin under vacuum pressure, resulting in a strong, lightweight composite with enhanced mechanical properties and uniform resin distribution. This method reduces void content and excess resin compared to Kevlar wet layup, leading to improved strength-to-weight ratio and durability. Kevlar resin infusion is ideal for high-performance applications such as aerospace and automotive components where structural integrity and weight savings are critical.

What is Kevlar Wet Layup?

Kevlar wet layup is a manual composite fabrication process where Kevlar fibers are impregnated with resin by hand before layering and curing. This technique allows for flexibility in complex shapes but often results in higher resin content and lower fiber-to-resin ratios compared to resin infusion methods. Wet layup is typically preferred for small-scale or custom applications due to its simplicity and lower equipment requirements.

Key Differences: Resin Infusion vs Wet Layup

Kevlar resin infusion uses vacuum pressure to draw resin through Kevlar fabric, resulting in higher fiber-to-resin ratio, superior strength, and better void reduction compared to wet layup. Wet layup involves manually saturating Kevlar with resin, leading to potential resin-rich areas and less consistent mechanical properties. Resin infusion offers improved structural performance and durability, while wet layup is more labor-intensive and prone to human error.

Material Properties Comparison

Kevlar resin infusion results in a composite with higher fiber-to-resin ratio, enhancing tensile strength and impact resistance compared to Kevlar wet layup, which often contains excess resin leading to reduced fiber efficiency. Resin infusion also improves void content and interlaminar bonding, increasing overall durability and fatigue resistance. Wet layup tends to produce composites with more variability in thickness and lower mechanical performance due to manual resin application inconsistencies.

Processing Time and Efficiency

Kevlar resin infusion significantly reduces processing time compared to Kevlar wet layup by enabling faster resin distribution through vacuum-assisted flow, enhancing overall production efficiency. The infusion method minimizes manual labor and material waste, ensuring consistent resin saturation and curing throughout the Kevlar composite structure. In contrast, Kevlar wet layup involves slower, labor-intensive hand application of epoxy resin, which increases processing time and introduces variability in composite quality.

Strength and Durability Outcomes

Kevlar resin infusion enhances fiber-to-resin bonding, resulting in superior strength and increased durability compared to traditional Kevlar wet layup methods. The infusion process ensures uniform resin distribution, minimizing voids and improving structural integrity under stress. Kevlar composites produced via resin infusion demonstrate higher resistance to impact and fatigue, extending the lifespan of protective gear and high-performance applications.

Cost Considerations for Each Method

Kevlar resin infusion typically demands higher upfront investment due to specialized equipment and controlled environments, but it offers greater material efficiency and reduced waste, leading to lower long-term costs. Kevlar wet layup requires less capital expenditure, making it more cost-effective for small-scale or prototype projects, although it often results in higher labor costs and material wastage. Choosing between these methods depends on project scale, budget constraints, and desired product quality.

Best Applications for Each Technique

Kevlar resin infusion excels in producing high-performance composite parts with superior strength-to-weight ratios, making it ideal for aerospace components, automotive body panels, and sporting goods that require precise resin control and minimal void content. Kevlar wet layup suits applications like marine repairs, prototyping, and small-scale fabrications where flexibility, ease of application, and low tooling costs outweigh the need for optimal fiber-to-resin ratios. Selecting resin infusion offers enhanced durability and structural integrity for critical load-bearing applications, while wet layup is preferred for rapid, cost-effective projects with moderate performance demands.

Choosing the Right Method for Your Kevlar Project

Kevlar resin infusion offers superior strength-to-weight ratios and enhanced fiber-to-resin bonding compared to Kevlar wet layup, making it ideal for high-performance applications demanding maximum durability. Wet layup, while more accessible and cost-effective for small-scale or prototype projects, may result in lower fiber impregnation and increased void content, potentially compromising structural integrity. Selecting the appropriate method depends on project scale, performance requirements, and budget constraints, with resin infusion favored for critical load-bearing parts and wet layup suitable for less demanding or experimental builds.

Kevlar resin infusion vs Kevlar wet layup Infographic

materialdif.com

materialdif.com