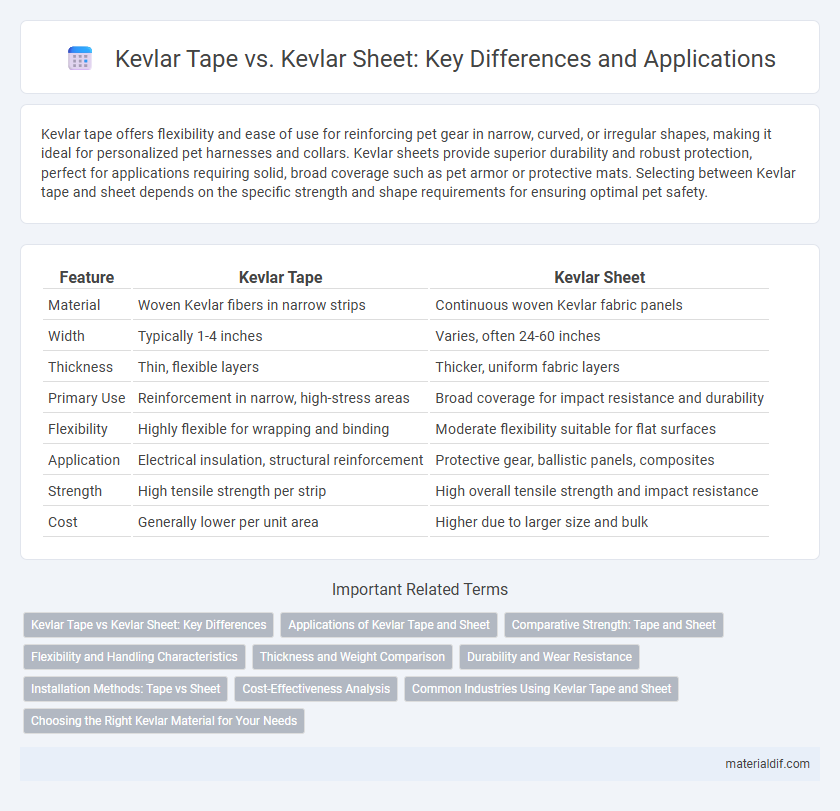

Kevlar tape offers flexibility and ease of use for reinforcing pet gear in narrow, curved, or irregular shapes, making it ideal for personalized pet harnesses and collars. Kevlar sheets provide superior durability and robust protection, perfect for applications requiring solid, broad coverage such as pet armor or protective mats. Selecting between Kevlar tape and sheet depends on the specific strength and shape requirements for ensuring optimal pet safety.

Table of Comparison

| Feature | Kevlar Tape | Kevlar Sheet |

|---|---|---|

| Material | Woven Kevlar fibers in narrow strips | Continuous woven Kevlar fabric panels |

| Width | Typically 1-4 inches | Varies, often 24-60 inches |

| Thickness | Thin, flexible layers | Thicker, uniform fabric layers |

| Primary Use | Reinforcement in narrow, high-stress areas | Broad coverage for impact resistance and durability |

| Flexibility | Highly flexible for wrapping and binding | Moderate flexibility suitable for flat surfaces |

| Application | Electrical insulation, structural reinforcement | Protective gear, ballistic panels, composites |

| Strength | High tensile strength per strip | High overall tensile strength and impact resistance |

| Cost | Generally lower per unit area | Higher due to larger size and bulk |

Kevlar Tape vs Kevlar Sheet: Key Differences

Kevlar tape offers greater flexibility and is ideal for wrapping or reinforcing irregular surfaces, while Kevlar sheets provide uniform strength and are better suited for large, flat applications requiring consistent impact resistance. The tape's narrow width allows precise application and easier layering, whereas sheets cover broader areas efficiently but can be less adaptable to complex shapes. Choosing between Kevlar tape and sheet depends on the specific structural requirements, with tape favored for detailed reinforcement and sheets preferred for extensive protective coverage.

Applications of Kevlar Tape and Sheet

Kevlar tape is commonly used in reinforcing cables, sports equipment, and composite materials due to its flexibility and ease of handling, allowing precise layering and wrapping around complex shapes. Kevlar sheets offer superior protection in bulletproof vests, body armor, and aerospace components, providing high tensile strength and impact resistance over larger surface areas. Both forms leverage Kevlar's exceptional durability and lightweight properties, tailoring their application to either detailed reinforcement or broad protective coverage.

Comparative Strength: Tape and Sheet

Kevlar tape offers superior tensile strength and flexibility, making it ideal for applications requiring precise wrapping or reinforcement in tight spaces. Kevlar sheets provide a broader surface area and uniform strength distribution, suitable for large-scale protective layering and impact resistance. Both materials leverage Kevlar's high modulus properties, but sheets typically excel in structural durability while tapes are preferred for localized strength and adaptability.

Flexibility and Handling Characteristics

Kevlar tape offers superior flexibility and ease of handling compared to Kevlar sheets, making it ideal for applications requiring precise wrapping and contouring. Its narrow width allows better maneuverability around complex shapes, enhancing adaptability in dynamic environments. Kevlar sheets, while providing greater coverage and structural strength, are stiffer and less conformable, limiting their use in tasks demanding intricate flexibility.

Thickness and Weight Comparison

Kevlar tape typically features a thinner profile, ranging from 0.1 to 0.3 millimeters, making it lightweight and flexible for applications requiring precise layering and contouring. Kevlar sheets generally have a thickness between 0.5 and 4 millimeters, offering increased structural strength and impact resistance but with a higher weight per unit area compared to tapes. Weight differences are significant as Kevlar tape weighs approximately 40 to 100 grams per square meter, whereas Kevlar sheets can exceed 200 grams per square meter depending on thickness and weave density.

Durability and Wear Resistance

Kevlar tape offers enhanced flexibility and ease of application in tight spaces, while Kevlar sheets provide superior durability and wear resistance due to their thicker, more uniform construction. The tightly woven fibers in Kevlar sheets result in higher tensile strength and better abrasion resistance, making them ideal for heavy-duty protective applications. In contrast, Kevlar tape, though durable, is more susceptible to fraying and wear under continuous mechanical stress.

Installation Methods: Tape vs Sheet

Kevlar tape offers flexible, easy-to-apply installation, ideal for wrapping irregular shapes and reinforcing seams with precision. Kevlar sheets require more careful handling and typically involve adhesive bonding or mechanical fastening, providing a rigid and uniform protective layer. Choosing between tape and sheet depends on surface contours and desired strength distribution in applications like protective gear or structural reinforcement.

Cost-Effectiveness Analysis

Kevlar tape offers enhanced versatility and precision for reinforcing joints and seams, often resulting in reduced material waste and labor costs compared to Kevlar sheets. Kevlar sheets provide comprehensive coverage suitable for large surface protection but typically demand higher initial investment and increased installation time, impacting overall cost-effectiveness. Choosing between Kevlar tape and sheets depends on project scale, with tape being more economical for targeted reinforcement and sheets better for extensive, uniform applications.

Common Industries Using Kevlar Tape and Sheet

Kevlar tape and Kevlar sheet are widely used in aerospace, automotive, and construction industries for their high tensile strength and impact resistance. Kevlar tape is favored in electrical insulation and tendon reinforcing applications, while Kevlar sheet excels in ballistic protection and composite manufacturing. Both forms enhance safety and durability in sports equipment manufacturing and marine applications.

Choosing the Right Kevlar Material for Your Needs

Kevlar tape offers flexibility and ease of application for wrapping and reinforcing curved surfaces, making it ideal for custom, intricate projects requiring high tensile strength and abrasion resistance. Kevlar sheets provide uniform thickness and rigidity, suitable for protective panels, ballistic armor, and structural reinforcement where consistent material properties are critical. Selecting the right Kevlar material depends on the specific application demands for flexibility, durability, and load-bearing capacity.

Kevlar tape vs Kevlar sheet Infographic

materialdif.com

materialdif.com