Kevlar offers exceptional abrasion resistance and high tensile strength, making it ideal for durable pet gear such as harnesses and leashes. Spectra is lighter and provides superior tensile strength per weight, ensuring lightweight protection without sacrificing strength. Both materials enhance pet safety, but Kevlar stands out for rugged durability while Spectra excels in lightweight performance.

Table of Comparison

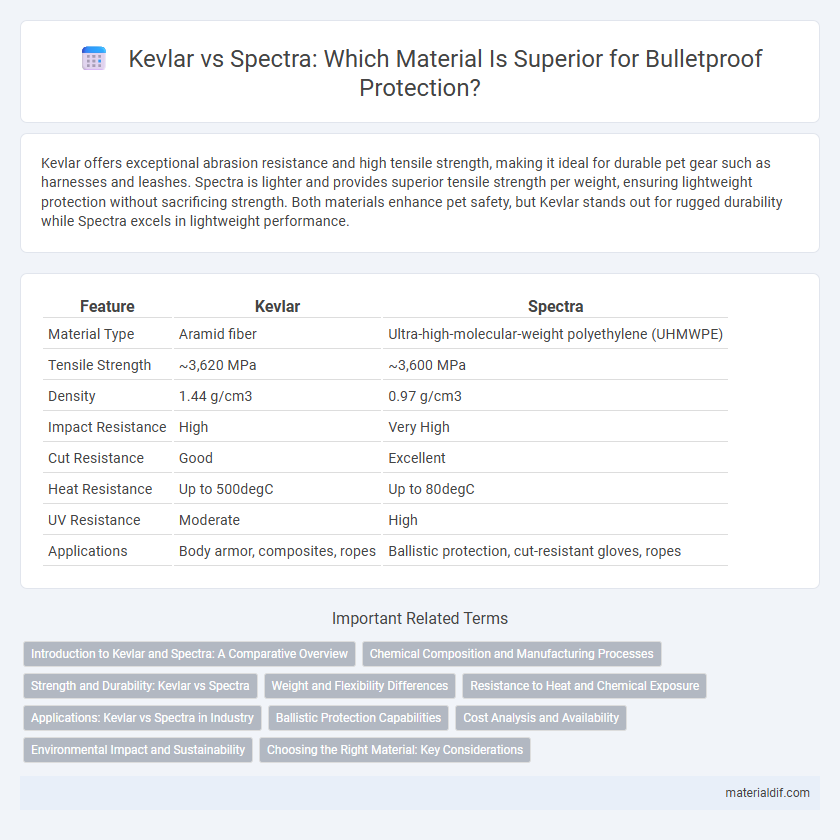

| Feature | Kevlar | Spectra |

|---|---|---|

| Material Type | Aramid fiber | Ultra-high-molecular-weight polyethylene (UHMWPE) |

| Tensile Strength | ~3,620 MPa | ~3,600 MPa |

| Density | 1.44 g/cm3 | 0.97 g/cm3 |

| Impact Resistance | High | Very High |

| Cut Resistance | Good | Excellent |

| Heat Resistance | Up to 500degC | Up to 80degC |

| UV Resistance | Moderate | High |

| Applications | Body armor, composites, ropes | Ballistic protection, cut-resistant gloves, ropes |

Introduction to Kevlar and Spectra: A Comparative Overview

Kevlar and Spectra are high-performance synthetic fibers prominently used in ballistic protection and industrial applications due to their exceptional strength-to-weight ratios. Kevlar, an aramid fiber developed by DuPont, is known for its thermal stability and tensile strength, while Spectra, a polyethylene-based fiber by Honeywell, offers superior impact resistance and low density. Both materials are integral to advanced body armor systems, with Kevlar excelling in heat resistance and Spectra providing enhanced cut and abrasion resistance.

Chemical Composition and Manufacturing Processes

Kevlar is a para-aramid synthetic fiber composed of poly-para-phenylene terephthalamide, characterized by its rigid molecular structure formed through a condensation polymerization process. Spectra, by contrast, is an ultra-high-molecular-weight polyethylene (UHMWPE) fiber produced via gel-spinning, resulting in long polymer chains oriented for superior tensile strength. The distinct chemical compositions and manufacturing techniques lead to Kevlar's exceptional thermal stability and Spectra's remarkable lightweight and resistance to moisture.

Strength and Durability: Kevlar vs Spectra

Kevlar exhibits superior tensile strength with a tensile strength of around 3,620 MPa, making it highly resistant to stretching and breaking under stress. Spectra, made from ultra-high-molecular-weight polyethylene, offers comparable strength but excels in impact resistance and abrasion durability. Kevlar maintains stability under high temperatures up to 450degC, whereas Spectra performs better in moisture resistance but has a lower melting point of about 147degC.

Weight and Flexibility Differences

Kevlar is heavier than Spectra, with Kevlar fibers typically weighing around 1.44 g/cm3 compared to Spectra's ultra-high molecular weight polyethylene at approximately 0.97 g/cm3, making Spectra significantly lighter. In terms of flexibility, Spectra exhibits greater pliability due to its polymer structure, allowing for easier movement and better conformity under stress, whereas Kevlar is stiffer and more rigid. These differences make Spectra preferable for lightweight, flexible applications like ballistic vests, while Kevlar is favored for high-strength, impact-resistant uses.

Resistance to Heat and Chemical Exposure

Kevlar exhibits superior resistance to heat, maintaining its structural integrity at temperatures up to 450degC, whereas Spectra begins to degrade around 150degC. In terms of chemical exposure, Kevlar is highly resistant to organic solvents and oils, while Spectra shows vulnerability to acids and prolonged UV exposure. This makes Kevlar the preferred choice for applications requiring high thermal stability and robust chemical resistance.

Applications: Kevlar vs Spectra in Industry

Kevlar is widely used in automotive and aerospace industries for its exceptional heat resistance and impact strength, making it ideal for protective gear and structural components. Spectra's ultra-high-molecular-weight polyethylene fibers excel in ballistic protection and lightweight composite materials, favored in military armor and high-performance sporting goods. Both materials offer superior durability, but Kevlar's thermal stability suits extreme environments while Spectra provides enhanced flexibility and moisture resistance in industrial applications.

Ballistic Protection Capabilities

Kevlar and Spectra are high-performance fibers known for ballistic protection, but they differ in material properties and performance. Kevlar, an aramid fiber, offers excellent tensile strength and heat resistance, making it highly effective against blunt force and shrapnel impacts. Spectra, a ultra-high-molecular-weight polyethylene (UHMWPE) fiber, provides superior energy absorption and a lower weight, resulting in enhanced ballistic resistance, especially against high-velocity projectiles.

Cost Analysis and Availability

Kevlar typically presents a higher cost due to its complex manufacturing process compared to Spectra, which is produced from ultra-high-molecular-weight polyethylene at a lower price point. In terms of availability, Kevlar benefits from widespread industrial application and extensive supply chains, making it more readily accessible in global markets. Spectra, while cost-effective, has more limited production facilities, impacting its availability in certain regions and specialized markets.

Environmental Impact and Sustainability

Kevlar and Spectra differ significantly in their environmental impact and sustainability profiles, with Kevlar being a synthetic aramid fiber derived from petroleum-based sources, resulting in higher carbon emissions during production. Spectra, made from ultra-high-molecular-weight polyethylene (UHMWPE), offers greater recyclability and a lower carbon footprint due to its energy-efficient manufacturing process. Evaluating lifecycle assessments reveals that Spectra's sustainable attributes make it a preferable choice for eco-conscious applications demanding strength and durability.

Choosing the Right Material: Key Considerations

Kevlar offers superior heat resistance and tensile strength, making it ideal for high-temperature and impact-resistant applications, while Spectra excels in lightweight durability and moisture resistance, suited for marine and ballistic uses. When choosing between Kevlar and Spectra, consider environmental factors such as exposure to UV radiation, with Kevlar being more UV-sensitive compared to Spectra's resilience. Cost efficiency, application-specific performance, and weight constraints are critical factors influencing the optimal selection between these high-performance fibers.

Kevlar vs Spectra Infographic

materialdif.com

materialdif.com