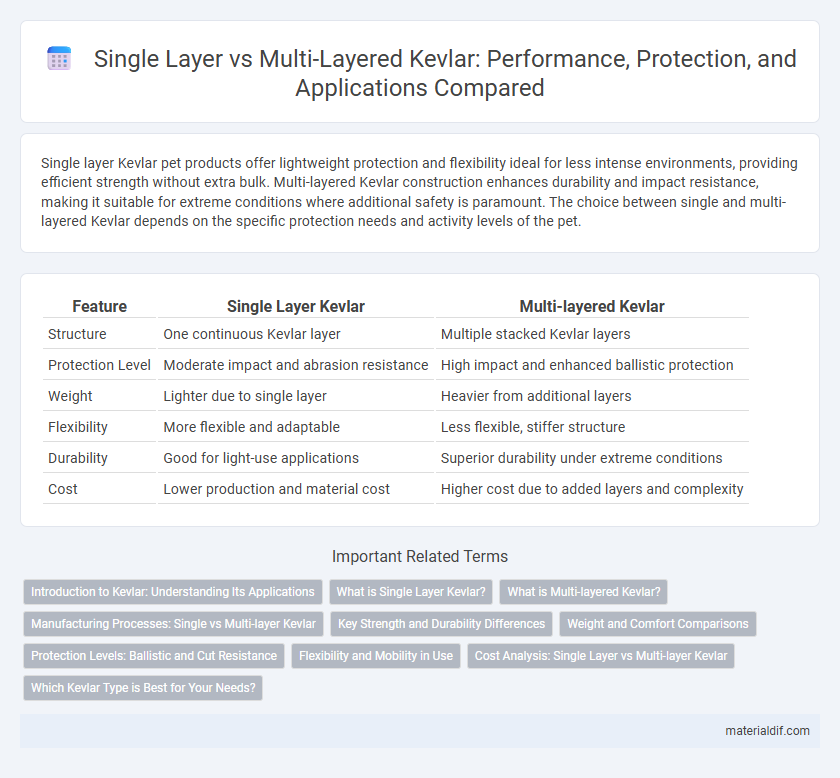

Single layer Kevlar pet products offer lightweight protection and flexibility ideal for less intense environments, providing efficient strength without extra bulk. Multi-layered Kevlar construction enhances durability and impact resistance, making it suitable for extreme conditions where additional safety is paramount. The choice between single and multi-layered Kevlar depends on the specific protection needs and activity levels of the pet.

Table of Comparison

| Feature | Single Layer Kevlar | Multi-layered Kevlar |

|---|---|---|

| Structure | One continuous Kevlar layer | Multiple stacked Kevlar layers |

| Protection Level | Moderate impact and abrasion resistance | High impact and enhanced ballistic protection |

| Weight | Lighter due to single layer | Heavier from additional layers |

| Flexibility | More flexible and adaptable | Less flexible, stiffer structure |

| Durability | Good for light-use applications | Superior durability under extreme conditions |

| Cost | Lower production and material cost | Higher cost due to added layers and complexity |

Introduction to Kevlar: Understanding Its Applications

Single-layer Kevlar provides high tensile strength and is primarily used in lightweight applications such as body armor and protective gloves, offering effective resistance to punctures and cuts. Multi-layered Kevlar enhances ballistic protection by increasing impact absorption and distributing force over multiple strata, commonly employed in bulletproof vests and vehicle armor. Each configuration is selected based on specific application requirements, balancing flexibility, weight, and protection level.

What is Single Layer Kevlar?

Single Layer Kevlar consists of a single sheet of woven Kevlar fibers designed to provide lightweight protection and flexibility. It is often used in applications requiring basic ballistic resistance, such as soft body armor and light protective gear. Compared to multi-layered Kevlar, it offers less impact absorption but maintains greater mobility and comfort.

What is Multi-layered Kevlar?

Multi-layered Kevlar consists of several stacked layers of Kevlar fabric woven to enhance strength, durability, and impact resistance compared to single-layer Kevlar. Each layer adds additional tensile strength and helps distribute force over a broader area, improving protection against ballistic threats and punctures. This composite structure is widely used in body armor, helmets, and protective gear to provide superior defense while maintaining flexibility and relatively low weight.

Manufacturing Processes: Single vs Multi-layer Kevlar

Single layer Kevlar is manufactured through a streamlined process involving the spinning of aramid fibers into a single, continuous sheet, resulting in lightweight and flexible material ideal for selective applications. Multi-layered Kevlar production requires stacking and bonding multiple sheets to enhance tensile strength and impact resistance, often involving advanced lamination or resin infusion techniques to ensure durability and structural integrity. The manufacturing complexity of multi-layered Kevlar allows for customization in thickness and protective properties, meeting diverse industry standards in ballistic and industrial safety gear.

Key Strength and Durability Differences

Single Layer Kevlar offers high tensile strength suitable for lightweight applications but has limited abrasion resistance compared to Multi-layered Kevlar, which significantly enhances durability through multiple overlapping fibers. Multi-layered Kevlar provides superior impact resistance and improved longevity, making it ideal for heavy-duty protective gear and ballistic armor. The increased layer count directly correlates with better energy absorption and fatigue resistance, ensuring prolonged performance under extreme conditions.

Weight and Comfort Comparisons

Single Layer Kevlar offers a lighter weight option, enhancing comfort and flexibility for extended wear, while providing substantial ballistic protection. Multi-layered Kevlar increases durability and impact resistance but adds significant weight, which may reduce overall comfort during prolonged use. The trade-off between weight and protection is crucial in applications prioritizing mobility and comfort versus maximum safety.

Protection Levels: Ballistic and Cut Resistance

Single-layer Kevlar offers substantial cut resistance and basic ballistic protection, typically stopping low-velocity projectiles and slashing threats. Multi-layered Kevlar enhances ballistic resistance significantly, enabling it to absorb and disperse the energy of high-velocity bullets and multiple impacts. The increased layering also improves cut resistance by providing a thicker composite barrier, making it more effective for high-risk situations in law enforcement and military applications.

Flexibility and Mobility in Use

Single layer Kevlar offers superior flexibility, allowing for greater mobility and comfort during use, making it ideal for lightweight protective gear. Multi-layered Kevlar, while providing enhanced ballistic resistance and durability, tends to reduce flexibility due to increased thickness and stiffness. Choosing between single and multi-layered Kevlar depends on the specific balance desired between mobility and protection in applications such as body armor or tactical clothing.

Cost Analysis: Single Layer vs Multi-layer Kevlar

Single layer Kevlar offers a lower initial cost due to reduced material usage and simpler manufacturing processes, making it suitable for budget-sensitive applications. Multi-layered Kevlar, while more expensive, provides enhanced ballistic protection and durability, justifying the higher cost in high-risk environments. The cost-benefit analysis favors single layer Kevlar for lightweight, cost-effective solutions, whereas multi-layered Kevlar delivers superior performance and safety despite increased expenses.

Which Kevlar Type is Best for Your Needs?

Single Layer Kevlar offers lightweight protection suitable for less intense impact scenarios, providing flexibility and comfort for everyday use. Multi-layered Kevlar enhances ballistic resistance and durability, making it ideal for high-risk environments requiring maximum defense against penetration. Choosing between them depends on balancing protection level, mobility, and specific activity demands to ensure optimal safety and performance.

Single Layer Kevlar vs Multi-layered Kevlar Infographic

materialdif.com

materialdif.com