Kevlar armor outperforms steel armor by offering superior flexibility and lighter weight, making it ideal for pet protection without restricting movement. Its high tensile strength efficiently absorbs and disperses impact energy, reducing injury risk more effectively than rigid steel plates. Kevlar also resists corrosion and extreme temperatures, ensuring durable and reliable defense in various environments.

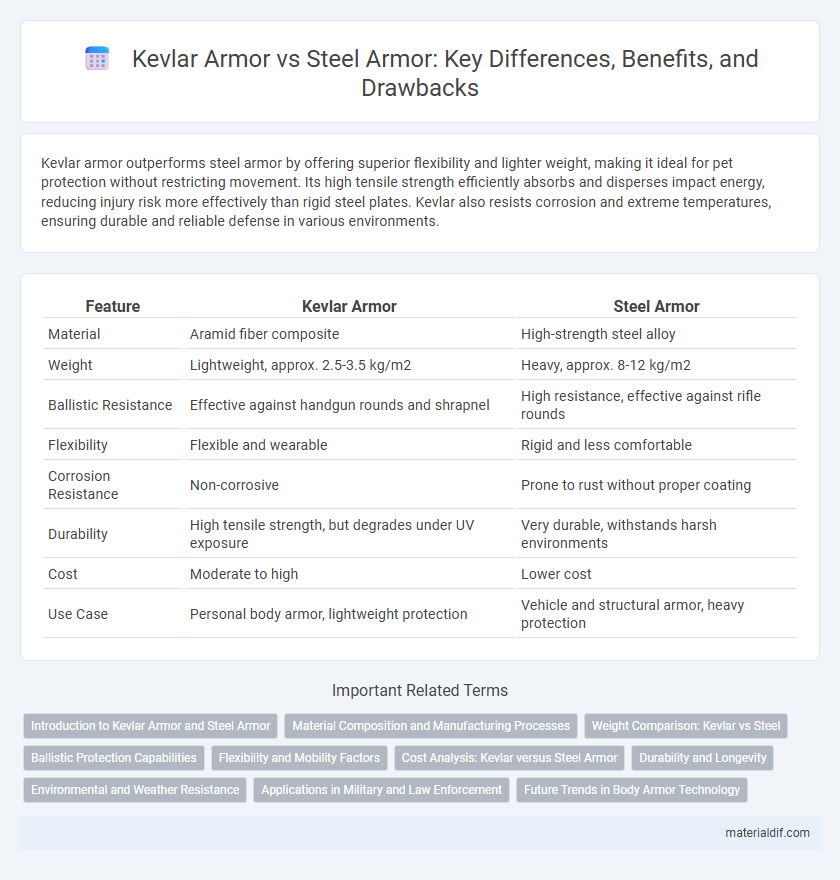

Table of Comparison

| Feature | Kevlar Armor | Steel Armor |

|---|---|---|

| Material | Aramid fiber composite | High-strength steel alloy |

| Weight | Lightweight, approx. 2.5-3.5 kg/m2 | Heavy, approx. 8-12 kg/m2 |

| Ballistic Resistance | Effective against handgun rounds and shrapnel | High resistance, effective against rifle rounds |

| Flexibility | Flexible and wearable | Rigid and less comfortable |

| Corrosion Resistance | Non-corrosive | Prone to rust without proper coating |

| Durability | High tensile strength, but degrades under UV exposure | Very durable, withstands harsh environments |

| Cost | Moderate to high | Lower cost |

| Use Case | Personal body armor, lightweight protection | Vehicle and structural armor, heavy protection |

Introduction to Kevlar Armor and Steel Armor

Kevlar armor, made from aramid fibers, offers exceptional tensile strength and lightweight protection compared to traditional steel armor. Steel armor provides robust ballistic resistance but is significantly heavier, impacting mobility and wearer comfort. The advanced fiber weave of Kevlar enables enhanced flexibility and energy absorption, making it ideal for modern ballistic protection applications.

Material Composition and Manufacturing Processes

Kevlar armor consists of tightly woven aramid fibers that provide high tensile strength and flexibility, enabling superior energy absorption compared to steel armor made from hardened metallic alloys known for rigidity and weight. The manufacturing process of Kevlar involves spinning liquid crystalline polymer into fibers followed by weaving into fabric, whereas steel armor is produced through casting, forging, and heat treatment to achieve desired hardness and impact resistance. Kevlar's composite layering technique enhances ballistic protection while maintaining lightweight characteristics, contrasting with steel armor's bulkier design required for comparable defense capabilities.

Weight Comparison: Kevlar vs Steel

Kevlar armor offers significant weight savings compared to steel armor, typically weighing up to five times less while providing comparable ballistic protection. The lightweight nature of Kevlar enhances mobility and reduces fatigue for users, especially in military and law enforcement applications. In contrast, steel armor, although durable, is considerably heavier, limiting agility and endurance during extended operations.

Ballistic Protection Capabilities

Kevlar armor provides superior ballistic protection due to its high tensile strength-to-weight ratio, effectively absorbing and dispersing the energy from bullets and shrapnel. Unlike steel armor, Kevlar is flexible and lightweight, allowing for greater mobility while maintaining resistance to penetration from handgun and rifle rounds. Modern ballistic Kevlar composites outperform steel armor in stopping power against high-velocity projectiles without the added weight burden.

Flexibility and Mobility Factors

Kevlar armor offers significantly greater flexibility and mobility compared to traditional steel armor due to its lightweight, woven aramid fibers that conform to body movements. This enhanced flexibility reduces fatigue and allows for quicker, more agile responses in combat scenarios. Unlike rigid steel plates, Kevlar's material design provides superior comfort without compromising ballistic protection.

Cost Analysis: Kevlar versus Steel Armor

Kevlar armor offers a favorable cost-to-performance ratio compared to steel armor, with raw material and manufacturing expenses often lower due to Kevlar's lightweight properties that reduce transportation and handling costs. While steel armor typically involves higher production and installation costs because of its weight and fabrication complexity, Kevlar provides cost efficiency in long-term maintenance and wear resistance. Budget-conscious defense and security sectors increasingly prefer Kevlar armor for its overall affordability combined with effective ballistic protection.

Durability and Longevity

Kevlar armor offers superior impact resistance and maintains flexibility, resulting in enhanced durability compared to traditional steel armor, which is prone to corrosion and deformation over time. Kevlar fibers resist wear and fatigue, ensuring long-term performance under repeated stress, whereas steel armor often requires regular maintenance to prevent rust and structural weakening. This makes Kevlar armor a more reliable and longer-lasting protective solution in dynamic and harsh environments.

Environmental and Weather Resistance

Kevlar armor offers superior environmental and weather resistance compared to traditional steel armor, as it is highly resistant to corrosion, rust, and moisture damage. Unlike steel, Kevlar maintains structural integrity and flexibility under extreme temperatures and humidity, making it ideal for diverse operational environments. This lightweight composite material also withstands UV exposure without significant degradation, ensuring long-lasting protective performance in harsh outdoor conditions.

Applications in Military and Law Enforcement

Kevlar armor offers superior ballistic protection with lightweight flexibility, making it ideal for military and law enforcement personnel requiring enhanced mobility during tactical operations. Steel armor provides robust defense against high-velocity projectiles but adds significant weight, limiting endurance and agility in the field. Kevlar's ability to absorb and disperse impact energy efficiently has made it the preferred choice in bulletproof vests, helmets, and vehicle armor utilized by armed forces and police units worldwide.

Future Trends in Body Armor Technology

Kevlar armor continues to evolve with advancements in fiber technology, offering enhanced strength-to-weight ratios compared to traditional steel armor. Future trends emphasize incorporating nanomaterials and hybrid composites to improve flexibility and ballistic resistance while reducing overall weight. Research in smart armor systems integrates sensors and adaptive materials for real-time threat detection and response, positioning Kevlar-based body armor at the forefront of next-generation personal protection.

Kevlar armor vs Steel armor Infographic

materialdif.com

materialdif.com