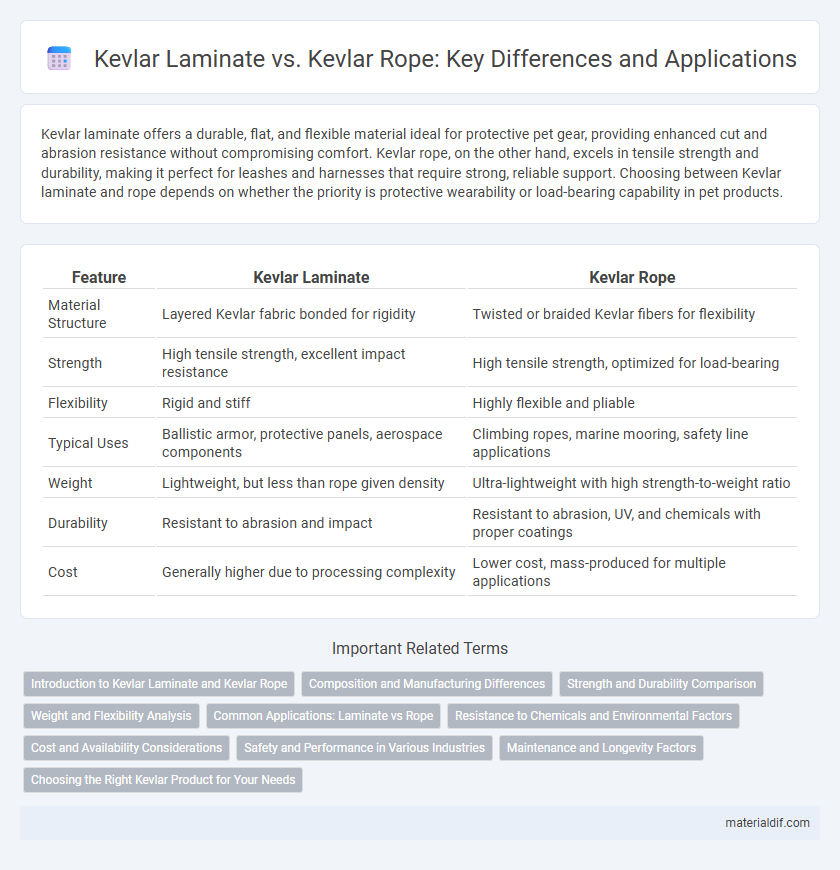

Kevlar laminate offers a durable, flat, and flexible material ideal for protective pet gear, providing enhanced cut and abrasion resistance without compromising comfort. Kevlar rope, on the other hand, excels in tensile strength and durability, making it perfect for leashes and harnesses that require strong, reliable support. Choosing between Kevlar laminate and rope depends on whether the priority is protective wearability or load-bearing capability in pet products.

Table of Comparison

| Feature | Kevlar Laminate | Kevlar Rope |

|---|---|---|

| Material Structure | Layered Kevlar fabric bonded for rigidity | Twisted or braided Kevlar fibers for flexibility |

| Strength | High tensile strength, excellent impact resistance | High tensile strength, optimized for load-bearing |

| Flexibility | Rigid and stiff | Highly flexible and pliable |

| Typical Uses | Ballistic armor, protective panels, aerospace components | Climbing ropes, marine mooring, safety line applications |

| Weight | Lightweight, but less than rope given density | Ultra-lightweight with high strength-to-weight ratio |

| Durability | Resistant to abrasion and impact | Resistant to abrasion, UV, and chemicals with proper coatings |

| Cost | Generally higher due to processing complexity | Lower cost, mass-produced for multiple applications |

Introduction to Kevlar Laminate and Kevlar Rope

Kevlar laminate consists of multiple layers of Kevlar fabric bonded together under heat and pressure, providing exceptional tensile strength and resistance to impact, ideal for ballistic protection and industrial applications. Kevlar rope is made by twisting or braiding Kevlar fibers into strong, lightweight cords used for climbing, rescue, and marine purposes due to its high strength-to-weight ratio and durability. Both forms leverage the inherent properties of Kevlar aramid fibers, such as high tensile strength, thermal stability, and chemical resistance, tailored for specific performance requirements.

Composition and Manufacturing Differences

Kevlar laminate consists of multiple layers of Kevlar fibers bonded together with resin through a compression molding process, resulting in a rigid, high-strength sheet used in ballistic armor and protective gear. Kevlar rope is made by twisting or braiding continuous Kevlar fibers into flexible strands, designed for tensile strength and flexibility in applications like climbing and industrial lifting. The main differences lie in manufacturing techniques--laminate employs layering and resin bonding for rigidity, while rope uses fiber twisting or braiding for durability and elasticity.

Strength and Durability Comparison

Kevlar laminate offers superior tensile strength and impact resistance due to its densely woven fiber layers, making it ideal for ballistic protection and armor applications. Kevlar rope, while highly durable and abrasion-resistant, provides excellent flexibility and load-bearing capacity but typically exhibits lower overall strength compared to laminate structures. The laminate's enhanced durability is attributed to its composite construction, which better distributes stress and resists wear over time compared to the rope's braided fiber design.

Weight and Flexibility Analysis

Kevlar laminate exhibits superior weight-to-strength ratio compared to traditional Kevlar rope, making it ideal for applications requiring lightweight yet durable materials. The laminate's layered construction enhances flexibility without compromising tensile strength, whereas Kevlar rope offers greater flexibility but with increased bulk and weight. Analysis shows that Kevlar laminate provides optimized performance in scenarios where minimal weight and controlled flexibility are critical design factors.

Common Applications: Laminate vs Rope

Kevlar laminate is commonly used in body armor, helmets, and cut-resistant gloves due to its high tensile strength and lightweight properties that provide superior ballistic and stab protection. Kevlar rope, known for its exceptional durability and resistance to abrasion, finds frequent application in marine environments, climbing, and industrial lifting where flexibility and toughness are critical. Each form leverages Kevlar's unique strength-to-weight ratio tailored to specific safety and performance requirements across various industries.

Resistance to Chemicals and Environmental Factors

Kevlar laminate offers superior resistance to chemicals and environmental factors compared to Kevlar rope due to its dense, tightly woven structure that minimizes exposure to corrosive agents. Kevlar laminate's polymer matrix protects against UV radiation, moisture, and solvents, enhancing longevity in harsh industrial and marine environments. In contrast, Kevlar rope, with its exposed fibers and flexible weave, is more susceptible to chemical degradation, abrasion, and weakening under prolonged environmental stress.

Cost and Availability Considerations

Kevlar laminate typically incurs higher costs due to its advanced manufacturing processes and is less widely available compared to Kevlar rope, which benefits from mass production and broader market supply. The price difference is significant in large-scale applications where budget constraints prioritize cost-effective materials without compromising strength. Availability of Kevlar rope is generally better in industrial and commercial sectors, making it a more accessible choice for many users.

Safety and Performance in Various Industries

Kevlar laminate offers superior impact resistance and structural reinforcement compared to Kevlar rope, making it ideal for ballistic protection and aerospace applications where rigid safety barriers are essential. Kevlar rope provides exceptional tensile strength and flexibility, widely used in maritime, climbing, and industrial lifting operations demanding durable, lightweight safety lines. Both materials leverage Kevlar's high tensile strength and heat resistance, but selecting between laminate and rope depends heavily on specific performance requirements and safety standards in various industries.

Maintenance and Longevity Factors

Kevlar laminate requires regular inspection for surface damage and UV exposure to maintain its tensile strength and durability, while Kevlar rope demands vigilant monitoring for abrasion, fraying, and moisture intrusion which can degrade fiber integrity over time. Laminate longevity is enhanced by proper storage away from direct sunlight and chemicals, whereas rope lifespan depends heavily on avoiding excessive bending and mechanical wear. Both materials benefit from routine cleaning with mild detergents to prevent contamination that accelerates fiber breakdown.

Choosing the Right Kevlar Product for Your Needs

Kevlar laminate offers superior tensile strength and abrasion resistance, making it ideal for applications requiring flat, flexible sheets such as protective gear and structural reinforcement. Kevlar rope, designed for high load-bearing capacity and flexibility, excels in marine, climbing, and industrial rigging tasks where durability and resistance to impact are critical. Selecting between Kevlar laminate and Kevlar rope depends on the specific mechanical demands and environmental conditions of your project.

Kevlar laminate vs Kevlar rope Infographic

materialdif.com

materialdif.com