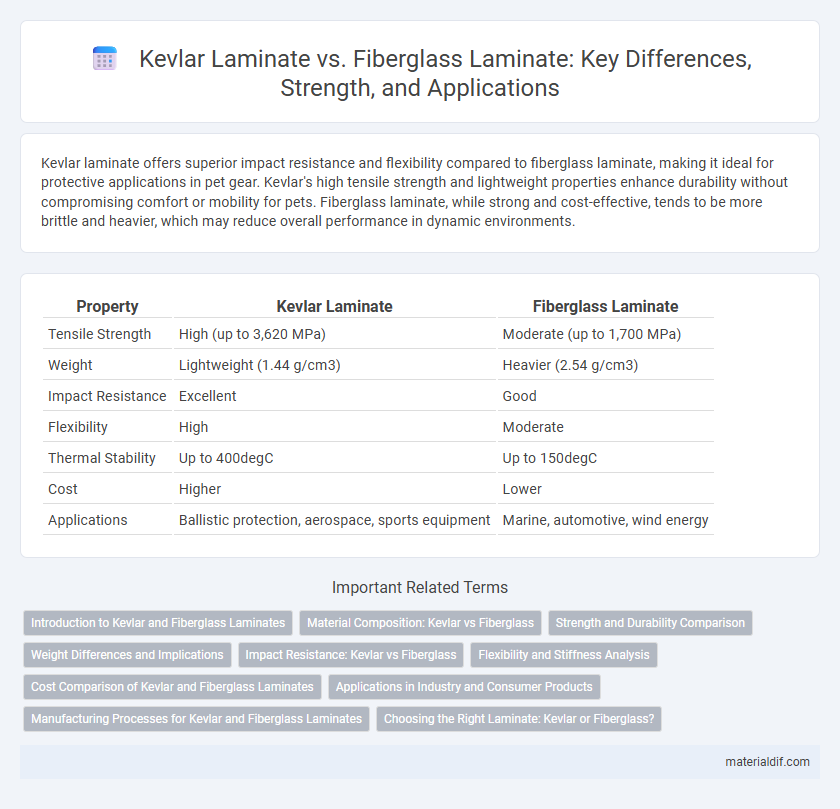

Kevlar laminate offers superior impact resistance and flexibility compared to fiberglass laminate, making it ideal for protective applications in pet gear. Kevlar's high tensile strength and lightweight properties enhance durability without compromising comfort or mobility for pets. Fiberglass laminate, while strong and cost-effective, tends to be more brittle and heavier, which may reduce overall performance in dynamic environments.

Table of Comparison

| Property | Kevlar Laminate | Fiberglass Laminate |

|---|---|---|

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 1,700 MPa) |

| Weight | Lightweight (1.44 g/cm3) | Heavier (2.54 g/cm3) |

| Impact Resistance | Excellent | Good |

| Flexibility | High | Moderate |

| Thermal Stability | Up to 400degC | Up to 150degC |

| Cost | Higher | Lower |

| Applications | Ballistic protection, aerospace, sports equipment | Marine, automotive, wind energy |

Introduction to Kevlar and Fiberglass Laminates

Kevlar laminate offers superior tensile strength and impact resistance compared to fiberglass laminate, making it a preferred choice in high-performance applications such as aerospace and ballistic protection. Fiberglass laminate provides excellent durability and cost-effectiveness, commonly used in automotive and marine industries for structural reinforcement. Both materials consist of layered fibers bonded with resin, but Kevlar's aramid fibers deliver enhanced toughness and energy absorption, distinguishing it from the glass fibers in fiberglass laminates.

Material Composition: Kevlar vs Fiberglass

Kevlar laminates consist primarily of aramid fibers known for exceptional tensile strength and impact resistance, whereas fiberglass laminates are made from woven glass fibers offering good stiffness and corrosion resistance. Kevlar's molecular structure provides superior energy absorption and lighter weight, making it ideal for high-performance composites. Fiberglass laminates, while more affordable and chemically inert, generally exhibit lower strength-to-weight ratios compared to Kevlar-based materials.

Strength and Durability Comparison

Kevlar laminate exhibits superior tensile strength and impact resistance compared to fiberglass laminate, making it ideal for applications requiring enhanced durability under high stress. Kevlar's molecular structure offers exceptional toughness and energy absorption, providing greater resistance to abrasion and fatigue over time. Fiberglass laminate, while cost-effective, generally lacks the long-term strength retention and puncture resistance that Kevlar laminates deliver in demanding environments.

Weight Differences and Implications

Kevlar laminate exhibits a significantly lower density of approximately 1.44 g/cm3 compared to fiberglass laminate's density of around 2.6 g/cm3, resulting in lighter composite structures. This weight difference translates to enhanced performance in applications such as aerospace, automotive, and sporting goods by improving fuel efficiency, agility, and handling. Reduced weight combined with Kevlar's high tensile strength also contributes to increased durability and impact resistance, making it an optimal choice for weight-sensitive and high-performance designs.

Impact Resistance: Kevlar vs Fiberglass

Kevlar laminate exhibits significantly higher impact resistance compared to fiberglass laminate, absorbing and dissipating energy more effectively due to its unique aramid fiber structure. This enhanced impact resistance makes Kevlar laminates ideal for applications requiring superior toughness, such as ballistic armor and protective gear. Fiberglass laminates, while strong and cost-effective, tend to be more brittle and prone to cracking under high-impact forces, limiting their use in high-impact environments.

Flexibility and Stiffness Analysis

Kevlar laminates exhibit higher flexibility compared to fiberglass laminates due to their molecular structure, which allows greater elongation under stress while maintaining strength. Fiberglass laminates offer increased stiffness, making them ideal for applications requiring rigidity but at the cost of reduced impact resistance and flexibility. The balance between Kevlar's flexibility and fiberglass's stiffness is critical in composite design for optimizing performance in aerospace and automotive industries.

Cost Comparison of Kevlar and Fiberglass Laminates

Kevlar laminates generally cost more than fiberglass laminates due to the higher price of aramid fibers and specialized manufacturing processes. Fiberglass offers a more budget-friendly option with adequate strength for many applications, making it popular in industries prioritizing cost-efficiency. The cost differential impacts project budgets, especially in large-scale production or high-performance uses where Kevlar's enhanced durability justifies the investment.

Applications in Industry and Consumer Products

Kevlar laminate offers superior tensile strength and impact resistance compared to fiberglass laminate, making it ideal for aerospace, automotive, and military applications where lightweight durability is crucial. Fiberglass laminate is commonly used in consumer products such as boat hulls, sports equipment, and construction due to its cost-effectiveness and corrosion resistance. The choice between Kevlar and fiberglass laminates depends on performance requirements, with Kevlar favored in high-stress environments and fiberglass in applications prioritizing affordability and versatility.

Manufacturing Processes for Kevlar and Fiberglass Laminates

Kevlar laminates are manufactured using a resin transfer molding or hand lay-up process, where Kevlar fibers are carefully aligned to optimize impact resistance and tensile strength. Fiberglass laminates typically employ a similar hand lay-up or spray-up method, but benefit from faster curing times and lower material costs, enhancing production efficiency. The unique manufacturing approach for Kevlar demands precise control of temperature and pressure to maintain fiber integrity, differentiating it from the more straightforward fiberglass laminate processes.

Choosing the Right Laminate: Kevlar or Fiberglass?

Kevlar laminate offers superior impact resistance and high tensile strength, making it ideal for applications requiring enhanced durability and lightweight protection, such as body armor and aerospace components. Fiberglass laminate excels in cost-effectiveness and chemical resistance, suitable for marine, automotive, and construction industries where budget and corrosion resistance are critical. Selecting between Kevlar and fiberglass laminates depends on performance priorities, with Kevlar preferred for strength-to-weight ratio and fiberglass favored for affordability and environmental resilience.

Kevlar laminate vs Fiberglass laminate Infographic

materialdif.com

materialdif.com