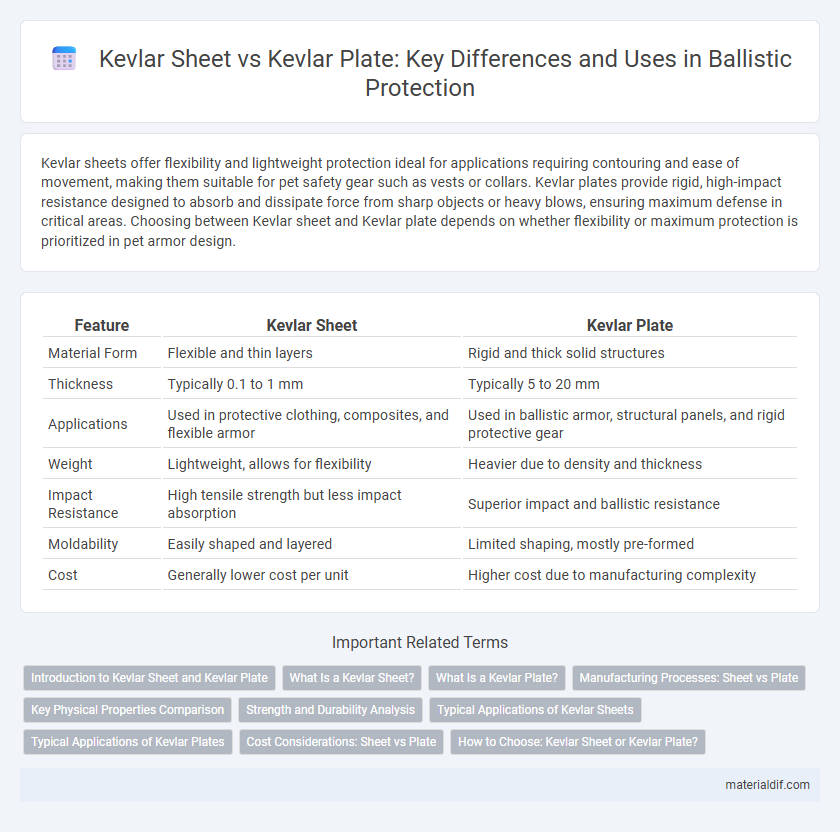

Kevlar sheets offer flexibility and lightweight protection ideal for applications requiring contouring and ease of movement, making them suitable for pet safety gear such as vests or collars. Kevlar plates provide rigid, high-impact resistance designed to absorb and dissipate force from sharp objects or heavy blows, ensuring maximum defense in critical areas. Choosing between Kevlar sheet and Kevlar plate depends on whether flexibility or maximum protection is prioritized in pet armor design.

Table of Comparison

| Feature | Kevlar Sheet | Kevlar Plate |

|---|---|---|

| Material Form | Flexible and thin layers | Rigid and thick solid structures |

| Thickness | Typically 0.1 to 1 mm | Typically 5 to 20 mm |

| Applications | Used in protective clothing, composites, and flexible armor | Used in ballistic armor, structural panels, and rigid protective gear |

| Weight | Lightweight, allows for flexibility | Heavier due to density and thickness |

| Impact Resistance | High tensile strength but less impact absorption | Superior impact and ballistic resistance |

| Moldability | Easily shaped and layered | Limited shaping, mostly pre-formed |

| Cost | Generally lower cost per unit | Higher cost due to manufacturing complexity |

Introduction to Kevlar Sheet and Kevlar Plate

Kevlar sheets are flexible, lightweight materials composed of woven aramid fibers, offering excellent tensile strength and impact resistance for applications requiring flexibility and contour adaptation. Kevlar plates, in contrast, are rigid, solid panels designed to provide enhanced ballistic protection and structural support in body armor and vehicle armor systems. The choice between Kevlar sheet and Kevlar plate depends on the specific need for flexibility versus maximum protection performance.

What Is a Kevlar Sheet?

A Kevlar sheet is a thin, flexible layer composed of woven Kevlar fibers designed for lightweight protection and impact resistance. Unlike rigid Kevlar plates, which provide structural strength and are used in ballistic armor, Kevlar sheets are often used in applications requiring flexibility, such as reinforcing composites, flexible armor, and protective clothing. The sheet form allows for easy layering and molding to complex shapes, enhancing versatility in various protective and industrial uses.

What Is a Kevlar Plate?

A Kevlar plate is a rigid or semi-rigid protective panel made from multiple layers of Kevlar fibers bound together, designed to provide enhanced ballistic resistance compared to Kevlar sheets. Unlike flexible Kevlar sheets, Kevlar plates offer superior impact absorption and structural integrity, making them ideal for use in body armor and vehicle armor systems. The density and layering technique in Kevlar plates significantly improve protection against high-velocity projectiles and blunt force trauma.

Manufacturing Processes: Sheet vs Plate

Kevlar sheets are produced through a continuous spinning and weaving process that creates flexible, fabric-like materials ideal for abrasion-resistant applications. Kevlar plates undergo a compression molding process where layers of Kevlar fabric are impregnated with resin and cured under heat and pressure to form rigid, impact-resistant structures. The manufacturing distinction between sheets and plates determines their mechanical properties, with sheets offering flexibility and plates providing enhanced ballistic protection.

Key Physical Properties Comparison

Kevlar sheets offer flexibility and lightweight properties, making them ideal for applications requiring contouring and impact resistance, while Kevlar plates provide higher tensile strength and enhanced ballistic protection due to their rigid structure. The density of Kevlar sheets typically ranges around 1.44 g/cm3, contributing to their pliability, compared to Kevlar plates with slightly increased density for reinforced durability. Both materials possess high tensile strength, approximately 3,620 MPa, but Kevlar plates maintain superior stiffness and compression resistance, catering to demanding structural and protective uses.

Strength and Durability Analysis

Kevlar sheets offer flexibility and lightweight strength, making them ideal for applications requiring impact resistance without added bulk, while Kevlar plates provide superior rigidity and enhanced durability for high-stress environments. The tensile strength of Kevlar plates typically measures higher due to their dense, layered construction, ensuring better resistance to punctures and abrasions compared to sheets. Durability analysis shows Kevlar plates outperform sheets in prolonged use scenarios, maintaining structural integrity under repeated mechanical stress.

Typical Applications of Kevlar Sheets

Kevlar sheets are widely used in applications requiring flexibility and lightweight reinforcement, such as ballistic vests, protective clothing, and composite materials in automotive and aerospace industries. Unlike Kevlar plates, sheets can be easily molded or layered to provide tailored impact resistance and durability in helmets, body armor inserts, and sporting goods. Their ability to conform to complex shapes makes Kevlar sheets ideal for applications demanding both protection and mobility.

Typical Applications of Kevlar Plates

Kevlar plates are commonly used in ballistic protection applications such as body armor, vehicle armor, and helmets due to their high tensile strength and impact resistance. Unlike Kevlar sheets, which offer flexibility for layered composites and soft body armor, Kevlar plates provide rigid structural defense against high-velocity projectiles and shrapnel. Their typical applications extend to military, law enforcement, and aerospace industries where enhanced durability and lightweight protection are critical.

Cost Considerations: Sheet vs Plate

Kevlar sheets typically offer a more cost-effective solution compared to Kevlar plates due to lower material thickness and manufacturing complexity. Kevlar plates, designed for high-impact resistance and ballistic protection, involve more intensive production processes that increase overall expenses. Budget-sensitive projects often favor Kevlar sheets for flexibility and affordability, while Kevlar plates are preferred for applications requiring maximum durability despite higher costs.

How to Choose: Kevlar Sheet or Kevlar Plate?

When deciding between Kevlar sheet and Kevlar plate, consider the application's impact resistance and flexibility requirements. Kevlar sheets provide lightweight, flexible protection ideal for wearable gear and layered composites, while Kevlar plates offer rigid, high-strength defense suited for ballistic armor and structural reinforcement. Evaluate factors such as thickness, tensile strength, and intended use environment to ensure optimal performance and durability.

Kevlar sheet vs Kevlar plate Infographic

materialdif.com

materialdif.com