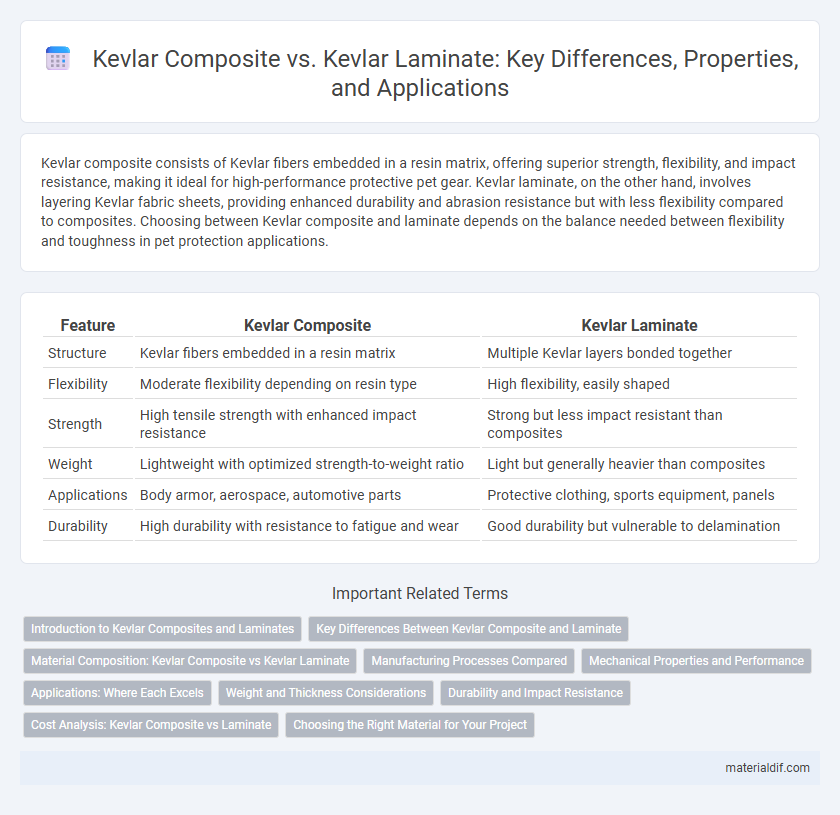

Kevlar composite consists of Kevlar fibers embedded in a resin matrix, offering superior strength, flexibility, and impact resistance, making it ideal for high-performance protective pet gear. Kevlar laminate, on the other hand, involves layering Kevlar fabric sheets, providing enhanced durability and abrasion resistance but with less flexibility compared to composites. Choosing between Kevlar composite and laminate depends on the balance needed between flexibility and toughness in pet protection applications.

Table of Comparison

| Feature | Kevlar Composite | Kevlar Laminate |

|---|---|---|

| Structure | Kevlar fibers embedded in a resin matrix | Multiple Kevlar layers bonded together |

| Flexibility | Moderate flexibility depending on resin type | High flexibility, easily shaped |

| Strength | High tensile strength with enhanced impact resistance | Strong but less impact resistant than composites |

| Weight | Lightweight with optimized strength-to-weight ratio | Light but generally heavier than composites |

| Applications | Body armor, aerospace, automotive parts | Protective clothing, sports equipment, panels |

| Durability | High durability with resistance to fatigue and wear | Good durability but vulnerable to delamination |

Introduction to Kevlar Composites and Laminates

Kevlar composites combine Kevlar fibers with resin matrices to create materials exhibiting high strength-to-weight ratios and exceptional impact resistance, widely used in aerospace and ballistic applications. Kevlar laminates consist of layered Kevlar fabrics bonded together, offering enhanced flexibility and tailored thickness for protective gear and structural panels. Both formats leverage Kevlar's superior tensile strength and lightweight properties but are engineered differently to optimize performance for specific industrial uses.

Key Differences Between Kevlar Composite and Laminate

Kevlar composite consists of Kevlar fibers embedded in a resin matrix, offering enhanced strength-to-weight ratio and superior impact resistance compared to Kevlar laminate, which is made by layering sheets of Kevlar fabric bonded together without resin. Kevlar composites provide better structural integrity and flexibility for aerospace and automotive applications, while Kevlar laminates are generally used in ballistic protection and lightweight armor due to their rigid, layered construction. The key difference lies in the manufacturing process and mechanical properties, where composites integrate fibers and resin for multidirectional strength whereas laminates rely on stacked fabric layers for improved tensile strength.

Material Composition: Kevlar Composite vs Kevlar Laminate

Kevlar composite consists of Kevlar fibers embedded in a resin matrix, offering enhanced strength, flexibility, and impact resistance for structural applications. Kevlar laminate is composed of multiple layers of Kevlar fabric bonded together without a resin matrix, resulting in a lightweight material primarily used for ballistic protection and puncture resistance. The distinct material composition influences the mechanical properties and ideal use cases of Kevlar composite and laminate in industries such as aerospace, automotive, and personal armor.

Manufacturing Processes Compared

Kevlar composite manufacturing involves embedding Kevlar fibers within a resin matrix using processes like resin transfer molding or compression molding to create strong, lightweight structural components. Kevlar laminate production typically consists of layering woven Kevlar fabric sheets bonded with adhesives or resins, followed by curing under heat and pressure to achieve enhanced surface protection and impact resistance. The composite process emphasizes fiber-matrix integration for mechanical strength, while lamination focuses on layering techniques to optimize flexibility and surface durability.

Mechanical Properties and Performance

Kevlar composites exhibit superior mechanical properties such as enhanced tensile strength, impact resistance, and flexibility compared to Kevlar laminates, due to their three-dimensional fiber orientation and resin matrix integration. Kevlar laminates, while providing excellent surface durability and dimensional stability, typically demonstrate lower impact absorption and tensile performance because of their layered structure with less effective load distribution. The performance of Kevlar composites in demanding applications like ballistic protection and aerospace components surpasses that of laminates, owing to better energy dissipation and resistance to delamination under stress.

Applications: Where Each Excels

Kevlar composite excels in applications demanding high tensile strength and impact resistance, such as ballistic armor, aerospace components, and automotive parts, where its fiber-reinforced polymer matrix offers superior durability and lightweight properties. Kevlar laminate is preferred in situations requiring layered protection and flexibility, including protective clothing, helmets, and sports equipment, benefiting from its multi-layered structure that enhances puncture resistance and comfort. Both materials leverage Kevlar's inherent strength but are optimized differently to meet specific functional requirements across diverse industries.

Weight and Thickness Considerations

Kevlar composites offer a superior strength-to-weight ratio compared to Kevlar laminates, resulting in lighter structures with enhanced durability. The thickness of Kevlar composites can be precisely controlled through fiber orientation and resin content, optimizing impact resistance without significantly increasing weight. In contrast, Kevlar laminates tend to be thicker and heavier due to their multiple layered construction, which may affect flexibility and overall material performance in weight-sensitive applications.

Durability and Impact Resistance

Kevlar composites exhibit superior durability and impact resistance compared to Kevlar laminates due to their engineered fiber alignment and resin matrix integration, which distribute stress more effectively across the material. Kevlar laminates, composed of stacked Kevlar fabric layers bonded with adhesives, tend to delaminate under high impact, reducing their structural integrity. The enhanced fiber-matrix bonding in Kevlar composites prevents crack propagation and improves energy absorption, making these materials ideal for high-performance protective applications.

Cost Analysis: Kevlar Composite vs Laminate

Kevlar composite materials typically incur higher costs compared to Kevlar laminates due to the complex manufacturing processes involved, including resin infusion and curing cycles. Kevlar laminates, constructed by layering Kevlar fabric with adhesive films, offer a more cost-effective solution with faster production times and reduced material waste. Cost analysis reveals that laminates are preferred in budget-conscious applications without compromising essential strength and impact resistance properties inherent to Kevlar.

Choosing the Right Material for Your Project

Kevlar Composite offers enhanced impact resistance and structural integrity by embedding Kevlar fibers within a resin matrix, making it ideal for applications requiring high strength-to-weight ratios such as aerospace and automotive parts. Kevlar Laminate consists of layered Kevlar sheets bonded together, providing excellent flexibility and durability suited for protective gear like body armor and sports equipment. Selecting between Kevlar Composite and Kevlar Laminate depends on the specific performance demands of your project, including weight considerations, mechanical stress, and environmental exposure.

Kevlar Composite vs Kevlar Laminate Infographic

materialdif.com

materialdif.com