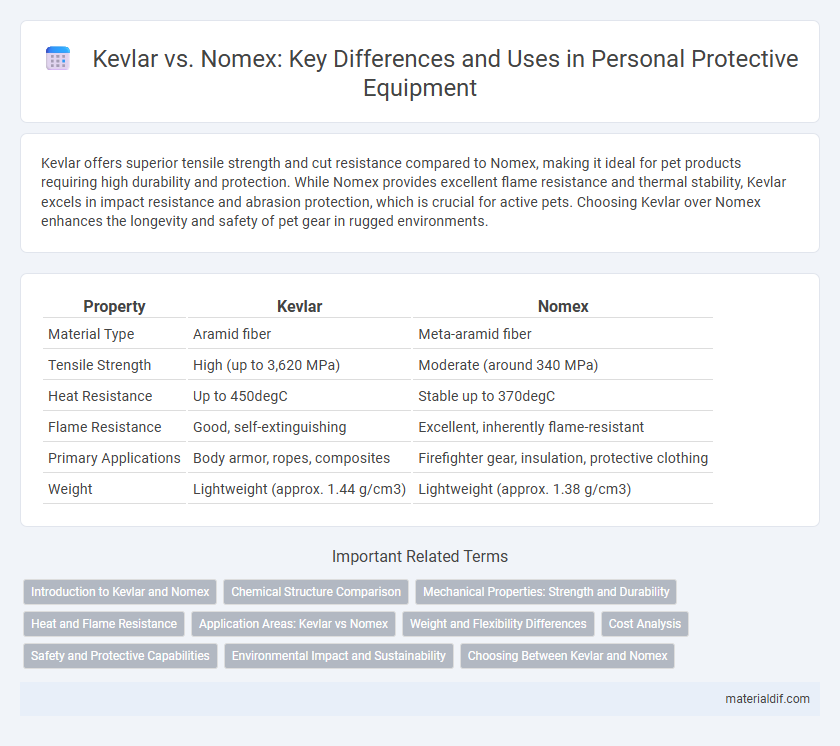

Kevlar offers superior tensile strength and cut resistance compared to Nomex, making it ideal for pet products requiring high durability and protection. While Nomex provides excellent flame resistance and thermal stability, Kevlar excels in impact resistance and abrasion protection, which is crucial for active pets. Choosing Kevlar over Nomex enhances the longevity and safety of pet gear in rugged environments.

Table of Comparison

| Property | Kevlar | Nomex |

|---|---|---|

| Material Type | Aramid fiber | Meta-aramid fiber |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (around 340 MPa) |

| Heat Resistance | Up to 450degC | Stable up to 370degC |

| Flame Resistance | Good, self-extinguishing | Excellent, inherently flame-resistant |

| Primary Applications | Body armor, ropes, composites | Firefighter gear, insulation, protective clothing |

| Weight | Lightweight (approx. 1.44 g/cm3) | Lightweight (approx. 1.38 g/cm3) |

Introduction to Kevlar and Nomex

Kevlar is a high-strength synthetic fiber known for its exceptional tensile strength and durability, widely used in body armor, aerospace, and industrial applications. Nomex, also a synthetic fiber, is primarily valued for its superior heat and flame resistance, making it ideal for protective clothing in firefighting and racing industries. Both materials originate from DuPont and serve specialized protective roles based on their unique chemical and physical properties.

Chemical Structure Comparison

Kevlar is an aromatic polyamide (aramid) characterized by rigid, planar polymer chains with para-oriented amide linkages that provide high tensile strength and thermal stability. Nomex, another aramid, has meta-oriented amide linkages resulting in a more flexible, less crystalline structure with enhanced flame resistance but lower tensile strength. The fundamental difference in chemical structure--para linkage in Kevlar versus meta linkage in Nomex--directly influences their mechanical properties and applications in protective gear.

Mechanical Properties: Strength and Durability

Kevlar exhibits superior tensile strength and exceptional abrasion resistance, making it highly durable in high-stress applications compared to Nomex. Nomex offers good mechanical strength but primarily excels in thermal resistance rather than extreme load-bearing capacity. The structural composition of Kevlar's aramid fibers provides enhanced toughness and resilience under mechanical strain, positioning it as the preferred choice for impact protection and reinforcement.

Heat and Flame Resistance

Kevlar offers excellent heat resistance with a decomposition temperature around 450degC, making it highly effective in protecting against high-temperature exposure. Nomex surpasses Kevlar in flame resistance due to its inherent flame-retardant properties and ability to withstand direct flames without melting or dripping. Both materials are widely used in protective gear, but Nomex is preferred for applications requiring superior flame resistance, while Kevlar excels in cut and abrasion resistance combined with heat tolerance.

Application Areas: Kevlar vs Nomex

Kevlar excels in applications requiring high tensile strength and impact resistance, such as body armor, aerospace components, and reinforced tires. Nomex is preferred for heat and flame resistance in protective gear, electrical insulation, and firefighting suits. Both materials are crucial in safety equipment but serve distinct roles based on their mechanical and thermal properties.

Weight and Flexibility Differences

Kevlar is lighter and more flexible than Nomex, making it ideal for applications requiring both protection and freedom of movement. Kevlar fibers have higher tensile strength-to-weight ratios, enhancing durability without adding bulk. Nomex offers superior heat resistance but tends to be heavier and less flexible compared to Kevlar, influencing its use in fire-resistant gear rather than lightweight body armor.

Cost Analysis

Kevlar is generally more expensive than Nomex due to its higher tensile strength and wider application in ballistic protection and industrial equipment. Nomex offers a cost-effective solution for flame-resistant clothing and thermal insulation, making it preferable for budget-conscious fire safety gear. Cost analysis favors Nomex in scenarios prioritizing flame resistance with moderate durability, while Kevlar justifies its price with superior abrasion resistance and impact protection.

Safety and Protective Capabilities

Kevlar provides superior cut and abrasion resistance, making it ideal for high-risk environments requiring enhanced physical protection. Nomex excels in thermal stability and flame resistance, offering critical protection against heat and fire hazards. Both materials play essential roles in safety gear, with Kevlar optimizing impact and puncture defense while Nomex prioritizes thermal and chemical protection.

Environmental Impact and Sustainability

Kevlar and Nomex both exhibit distinct environmental profiles, with Kevlar demonstrating higher durability and resistance to degradation, resulting in longer product lifespans that reduce waste. Nomex, while also flame-resistant, degrades more quickly under environmental stress, leading to a greater frequency of replacement and potential waste accumulation. Sustainable practices in Kevlar production emphasize resource efficiency and recyclability, positioning Kevlar as a more environmentally favorable choice in high-performance applications.

Choosing Between Kevlar and Nomex

Kevlar offers superior tensile strength and cut resistance, making it ideal for applications requiring high durability, such as body armor and industrial gloves. Nomex excels in flame resistance and thermal protection, preferred in firefighting gear and aerospace environments. Choosing between Kevlar and Nomex depends on whether impact resistance or heat protection is the primary safety concern.

Kevlar vs Nomex Infographic

materialdif.com

materialdif.com