Kevlar mesh offers superior flexibility and lightweight durability compared to stainless steel mesh, making it ideal for pet protective gear that requires comfort and resilience. Stainless steel mesh provides exceptional strength and puncture resistance but tends to be heavier and less comfortable for pets during extended wear. Choosing between Kevlar and stainless steel mesh depends on balancing the need for lightweight protection with maximum toughness.

Table of Comparison

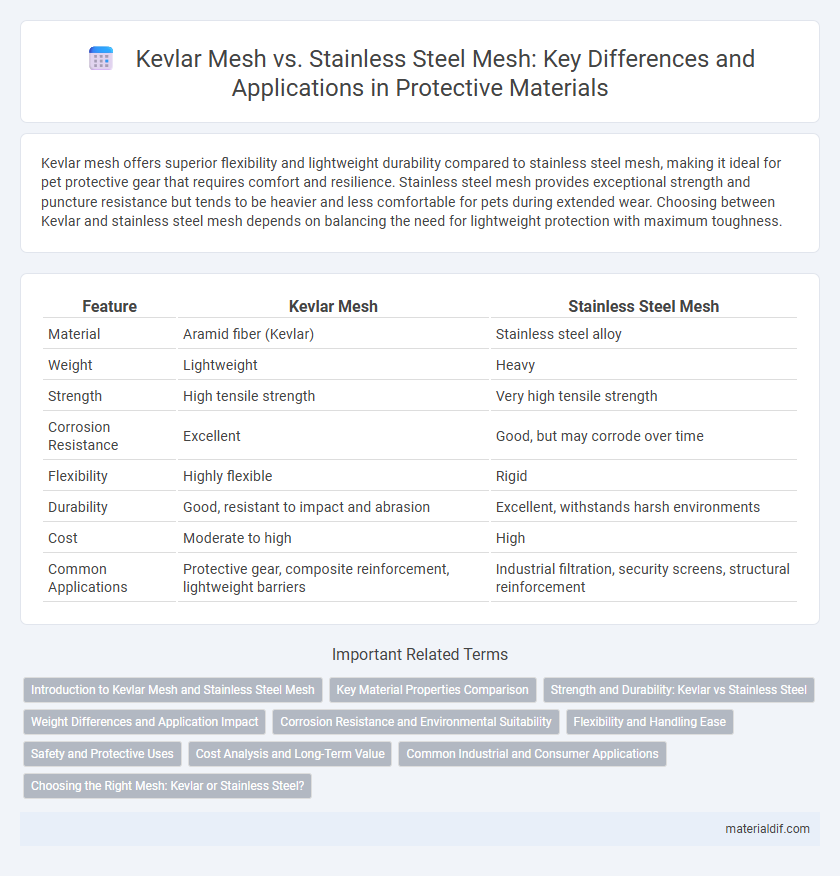

| Feature | Kevlar Mesh | Stainless Steel Mesh |

|---|---|---|

| Material | Aramid fiber (Kevlar) | Stainless steel alloy |

| Weight | Lightweight | Heavy |

| Strength | High tensile strength | Very high tensile strength |

| Corrosion Resistance | Excellent | Good, but may corrode over time |

| Flexibility | Highly flexible | Rigid |

| Durability | Good, resistant to impact and abrasion | Excellent, withstands harsh environments |

| Cost | Moderate to high | High |

| Common Applications | Protective gear, composite reinforcement, lightweight barriers | Industrial filtration, security screens, structural reinforcement |

Introduction to Kevlar Mesh and Stainless Steel Mesh

Kevlar mesh is a lightweight, high-strength material known for its exceptional tensile strength and resistance to impact, commonly used in protective applications and industrial filters. Stainless steel mesh offers superior corrosion resistance and durability, making it ideal for environments requiring toughness and longevity under harsh conditions. Both meshes serve critical roles in filtration, reinforcement, and protective gear, with Kevlar excelling in flexibility and stainless steel in robustness.

Key Material Properties Comparison

Kevlar mesh exhibits exceptional tensile strength, lightweight characteristics, and superior impact resistance compared to stainless steel mesh, which is heavier and more prone to corrosion despite its durability. Kevlar's high strength-to-weight ratio and flexibility make it ideal for applications requiring shock absorption and lightweight reinforcement, whereas stainless steel mesh offers better thermal resistance and rigidity. Both materials provide specific advantages, but Kevlar's unique polymer composition delivers enhanced toughness and fatigue resistance for advanced protective uses.

Strength and Durability: Kevlar vs Stainless Steel

Kevlar mesh offers exceptional tensile strength and resistance to impact, making it highly durable under extreme stress conditions, while stainless steel mesh excels in corrosion resistance and long-term wear in harsh environments. Kevlar's lightweight nature significantly enhances flexibility and reduces fatigue, whereas stainless steel mesh provides superior rigidity and structural support. Both materials deliver robust durability, but Kevlar outperforms in strength-to-weight ratio and resistance to fatigue, whereas stainless steel excels in chemical and thermal stability.

Weight Differences and Application Impact

Kevlar mesh offers significantly lower weight compared to stainless steel mesh, reducing overall structural load and enhancing ease of installation in aerospace, automotive, and sporting goods applications. The lightweight nature of Kevlar contributes to improved fuel efficiency and agility, making it ideal for performance-critical environments where weight reduction is paramount. Stainless steel mesh, while heavier, provides superior corrosion resistance and durability, making it suitable for industrial and marine uses where longevity and strength outweigh weight considerations.

Corrosion Resistance and Environmental Suitability

Kevlar mesh exhibits superior corrosion resistance compared to stainless steel mesh, as it is inherently non-metallic and immune to rust or chemical degradation in harsh environments. Its lightweight and flexible properties make it highly suitable for applications exposed to moisture, saltwater, and acidic conditions where stainless steel meshes might suffer from pitting or crevice corrosion. Kevlar's durability in marine, industrial, and outdoor settings ensures long-lasting performance without the maintenance challenges associated with metal corrosion.

Flexibility and Handling Ease

Kevlar mesh offers superior flexibility compared to stainless steel mesh, making it ideal for applications that require easy manipulation and contouring. Its lightweight nature enhances handling ease, allowing for quicker installation and reduced fatigue during prolonged use. Stainless steel mesh, while durable, tends to be stiffer and heavier, limiting flexibility and increasing handling difficulty in complex or tight spaces.

Safety and Protective Uses

Kevlar mesh offers superior safety benefits compared to stainless steel mesh due to its high tensile strength and exceptional resistance to impact and abrasion, making it ideal for protective applications such as bulletproof vests and cut-resistant gloves. Unlike stainless steel, Kevlar is lightweight and flexible, enhancing user comfort without compromising durability in hazardous environments. Its non-corrosive properties ensure reliable long-term protection in both wet and dry conditions, critical for safety gear performance.

Cost Analysis and Long-Term Value

Kevlar mesh offers a lower initial cost compared to stainless steel mesh due to its lightweight synthetic composition and ease of installation. While stainless steel mesh involves higher upfront expenses, its superior corrosion resistance and durability can result in reduced maintenance and replacement costs over time. Evaluating long-term value, Kevlar provides significant savings in applications requiring flexibility and weight reduction, whereas stainless steel delivers better return on investment in harsh, corrosive environments.

Common Industrial and Consumer Applications

Kevlar mesh offers exceptional strength-to-weight ratio and chemical resistance, making it ideal for industrial applications such as protective gear, filtration systems, and reinforcement in composites. Stainless steel mesh excels in durability and corrosion resistance, commonly used in heavy-duty screening, architectural facades, and food processing equipment. Both materials serve critical roles in consumer products, with Kevlar providing lightweight protection in sporting goods and stainless steel ensuring longevity in household appliances.

Choosing the Right Mesh: Kevlar or Stainless Steel?

Kevlar mesh offers superior strength-to-weight ratio and excellent corrosion resistance compared to stainless steel mesh, making it ideal for applications requiring lightweight durability. Stainless steel mesh provides high tensile strength and exceptional heat resistance, suitable for environments with extreme temperatures or heavy mechanical stress. Selecting between Kevlar and stainless steel mesh depends on specific needs such as weight constraints, environmental exposure, and mechanical demands.

Kevlar mesh vs Stainless steel mesh Infographic

materialdif.com

materialdif.com