Kevlar composite offers superior impact resistance and flexibility compared to carbon fiber composite, making it ideal for pet products requiring durability and shock absorption. Carbon fiber composite provides higher stiffness and strength-to-weight ratio, suitable for lightweight yet rigid pet accessories. Choosing between Kevlar and carbon fiber composites depends on balancing toughness with structural rigidity to meet specific pet product demands.

Table of Comparison

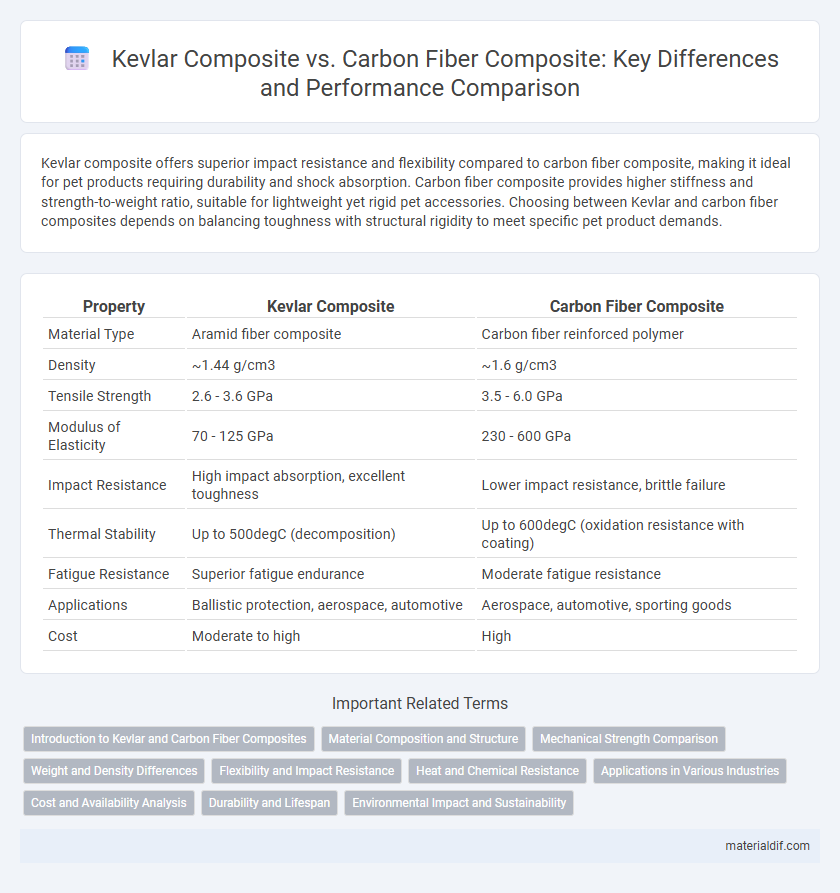

| Property | Kevlar Composite | Carbon Fiber Composite |

|---|---|---|

| Material Type | Aramid fiber composite | Carbon fiber reinforced polymer |

| Density | ~1.44 g/cm3 | ~1.6 g/cm3 |

| Tensile Strength | 2.6 - 3.6 GPa | 3.5 - 6.0 GPa |

| Modulus of Elasticity | 70 - 125 GPa | 230 - 600 GPa |

| Impact Resistance | High impact absorption, excellent toughness | Lower impact resistance, brittle failure |

| Thermal Stability | Up to 500degC (decomposition) | Up to 600degC (oxidation resistance with coating) |

| Fatigue Resistance | Superior fatigue endurance | Moderate fatigue resistance |

| Applications | Ballistic protection, aerospace, automotive | Aerospace, automotive, sporting goods |

| Cost | Moderate to high | High |

Introduction to Kevlar and Carbon Fiber Composites

Kevlar composites consist of aramid fibers known for exceptional toughness and impact resistance, making them ideal for ballistic and protective applications. Carbon fiber composites feature carbon fibers bonded in a polymer matrix, offering superior stiffness, strength, and lightweight properties used extensively in aerospace and automotive industries. Both composites optimize performance through distinct fiber architectures and resin systems, catering to specific engineering demands.

Material Composition and Structure

Kevlar composite consists of aramid fibers known for high tensile strength and exceptional impact resistance, with a molecular structure featuring strong hydrogen bonding that enhances toughness and flexibility. Carbon fiber composite is made from carbon fibers embedded in a polymer matrix, characterized by a highly crystalline graphite structure that provides superior stiffness and compressive strength. The fundamental difference lies in Kevlar's fibrous network offering excellent energy absorption, while carbon fiber's rigid lattice delivers unmatched rigidity and dimensional stability.

Mechanical Strength Comparison

Kevlar composite exhibits superior tensile strength and impact resistance compared to carbon fiber composite, making it ideal for applications requiring high durability and energy absorption. Carbon fiber composite, while offering higher stiffness and compressive strength, tends to be more brittle under sudden stress or impact. The choice between Kevlar and carbon fiber composites depends on the specific mechanical load requirements, balancing toughness and stiffness in engineering designs.

Weight and Density Differences

Kevlar composites exhibit a lower density of approximately 1.44 g/cm3 compared to carbon fiber composites, which range from 1.6 to 1.8 g/cm3, making Kevlar inherently lighter. This weight advantage contributes to superior impact resistance and flexibility in applications such as aerospace and personal protective equipment. Despite being lighter, Kevlar composites maintain high tensile strength, though carbon fiber composites typically offer greater stiffness and compressive strength.

Flexibility and Impact Resistance

Kevlar composites exhibit superior impact resistance compared to carbon fiber composites, absorbing and dissipating energy more effectively due to their aramid fiber structure. While carbon fiber composites provide higher stiffness and tensile strength, Kevlar composites offer greater flexibility, allowing for better deformation without fracturing under stress. This balance of flexibility and impact resistance makes Kevlar composites ideal for applications requiring durable protection against dynamic impacts.

Heat and Chemical Resistance

Kevlar composites exhibit superior heat resistance, maintaining structural integrity up to approximately 450degC, while carbon fiber composites typically degrade around 200degC to 300degC depending on the resin matrix. Kevlar's exceptional chemical resistance protects against acids, alkalis, and solvents, making it ideal for harsh chemical environments where carbon fiber composites may suffer resin matrix degradation. These properties make Kevlar composites preferred in applications requiring high thermal stability and chemical durability, such as aerospace, automotive, and protective gear manufacturing.

Applications in Various Industries

Kevlar composites offer superior impact resistance and flexibility, making them ideal for applications in body armor, aerospace, and automotive industries where durability and lightweight protection are critical. Carbon fiber composites provide higher stiffness and tensile strength, which suits structural components in aerospace, automotive racing, and sporting goods requiring rigidity and performance. Both materials are extensively used across industries to optimize performance based on specific strength, weight, and durability needs.

Cost and Availability Analysis

Kevlar composites typically offer a lower cost compared to carbon fiber composites, making them a more budget-friendly option for applications requiring high impact resistance. Kevlar's widespread availability and established supply chain contribute to its cost-effectiveness, while carbon fiber tends to be more expensive due to complex manufacturing processes and limited raw material supplies. Companies often choose Kevlar composites when balancing performance needs with tighter cost constraints and faster procurement timelines.

Durability and Lifespan

Kevlar composites exhibit exceptional durability due to their high resistance to impact, abrasion, and fatigue, extending the lifespan of products in demanding applications. In comparison, carbon fiber composites offer superior stiffness and strength but are more prone to brittle failures that can reduce long-term durability. The inherent toughness and energy absorption characteristics of Kevlar composites make them ideal for applications requiring extended service life under harsh conditions.

Environmental Impact and Sustainability

Kevlar composite offers a lower carbon footprint during production compared to carbon fiber composite, primarily due to less energy-intensive manufacturing processes. Kevlar's high durability and resistance to wear extend product lifespan, reducing overall material consumption and waste generation. Recycling Kevlar composites remains challenging but shows promise in closed-loop systems, whereas carbon fiber recycling is more established yet energetically costly.

Kevlar composite vs Carbon fiber composite Infographic

materialdif.com

materialdif.com