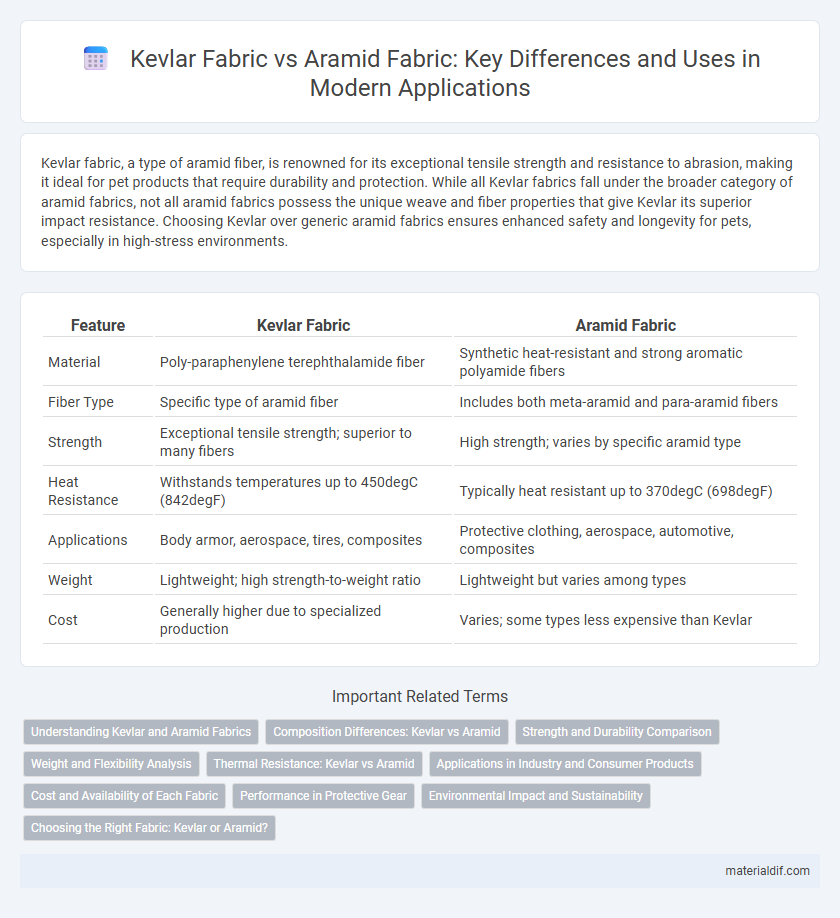

Kevlar fabric, a type of aramid fiber, is renowned for its exceptional tensile strength and resistance to abrasion, making it ideal for pet products that require durability and protection. While all Kevlar fabrics fall under the broader category of aramid fabrics, not all aramid fabrics possess the unique weave and fiber properties that give Kevlar its superior impact resistance. Choosing Kevlar over generic aramid fabrics ensures enhanced safety and longevity for pets, especially in high-stress environments.

Table of Comparison

| Feature | Kevlar Fabric | Aramid Fabric |

|---|---|---|

| Material | Poly-paraphenylene terephthalamide fiber | Synthetic heat-resistant and strong aromatic polyamide fibers |

| Fiber Type | Specific type of aramid fiber | Includes both meta-aramid and para-aramid fibers |

| Strength | Exceptional tensile strength; superior to many fibers | High strength; varies by specific aramid type |

| Heat Resistance | Withstands temperatures up to 450degC (842degF) | Typically heat resistant up to 370degC (698degF) |

| Applications | Body armor, aerospace, tires, composites | Protective clothing, aerospace, automotive, composites |

| Weight | Lightweight; high strength-to-weight ratio | Lightweight but varies among types |

| Cost | Generally higher due to specialized production | Varies; some types less expensive than Kevlar |

Understanding Kevlar and Aramid Fabrics

Kevlar fabric is a specific type of aramid fabric known for its exceptional tensile strength and heat resistance, making it ideal for ballistic and protective applications. While all Kevlar fabrics fall under the aramid category, aramid fabrics include various other fibers such as Nomex, which emphasize heat and flame resistance rather than the high-strength properties Kevlar provides. Understanding the distinctions between Kevlar and other aramid fabrics enables precise selection of material based on performance needs like impact resistance, durability, and thermal stability.

Composition Differences: Kevlar vs Aramid

Kevlar fabric is a specific type of aramid fabric composed primarily of poly-paraphenylene terephthalamide, which provides exceptional strength and heat resistance. While all Kevlar is aramid, aramid fabric encompasses a broader category including other variants like Nomex, which differ in chemical structure and application focus. Kevlar's molecular alignment offers superior tensile strength and impact resistance compared to other aramid types, making it ideal for ballistic and protective gear.

Strength and Durability Comparison

Kevlar fabric, a well-known type of aramid fiber, exhibits exceptional strength with tensile strength around 3,620 MPa, surpassing many other aramid fibers. Its unique molecular structure provides outstanding durability and resistance to impact, abrasion, and heat, making Kevlar highly suitable for ballistic and industrial applications. While all aramid fabrics offer superior performance compared to conventional materials, Kevlar's specific composition delivers a balanced combination of strength and durability optimized for protective gear and reinforcement uses.

Weight and Flexibility Analysis

Kevlar fabric is a specific type of aramid fabric known for its exceptional strength-to-weight ratio, offering a lighter yet durable alternative compared to generic aramid fabrics. Kevlar's molecular structure provides superior flexibility, enabling it to bend without breaking, which enhances comfort and mobility in protective gear. In weight comparison, Kevlar typically weighs less than other aramid variants, making it ideal for applications where both lightweight and flexibility are critical.

Thermal Resistance: Kevlar vs Aramid

Kevlar fabric exhibits superior thermal resistance compared to generic aramid fabrics, maintaining structural integrity at temperatures up to 450degC (842degF). While all aramid fabrics offer inherent flame resistance and thermal stability, Kevlar's tightly woven molecular structure enhances its durability against high heat and thermal degradation. This makes Kevlar a preferred choice in applications demanding exceptional heat protection and flame retardancy.

Applications in Industry and Consumer Products

Kevlar fabric, a specific type of aramid fiber, is widely used in body armor, helmets, and aerospace components due to its high tensile strength and impact resistance. Aramid fabric, encompassing Kevlar and other variants like Nomex, finds broader applications including industrial protective clothing, automotive fuel lines, and electrical insulation. In consumer products, Kevlar's superior durability enhances items such as high-performance sporting goods and reinforced tires, while other aramids offer heat resistance beneficial for firefighting gear and protective gloves.

Cost and Availability of Each Fabric

Kevlar fabric, a well-known aramid fiber, generally offers higher availability due to extensive commercial production and widespread industrial use, making it more accessible for various applications. In contrast, other aramid fabrics, such as Twaron or Nomex, may have variable availability depending on regional suppliers and manufacturing capacity, often resulting in higher costs. Kevlar's cost-effectiveness is driven by its mass production scale, whereas specialty aramid fabrics typically incur premium prices due to limited production and specialized performance characteristics.

Performance in Protective Gear

Kevlar fabric, a type of aramid fiber, offers exceptional tensile strength and impact resistance, making it ideal for high-performance protective gear such as bulletproof vests and helmets. Compared to general aramid fabrics, Kevlar delivers superior durability and thermal stability while maintaining lightweight comfort for extended wear. Its resistance to abrasion and cutting enhances its reliability in tactical and industrial applications where maximum protection is critical.

Environmental Impact and Sustainability

Kevlar fabric, a specific type of aramid fiber, exhibits considerable environmental challenges due to its energy-intensive production process and non-biodegradable nature. In comparison, some alternative aramid fabrics incorporate advancements in recycling and lower carbon emissions, enhancing their overall sustainability profile. Innovations in aramid fiber recycling and the development of bio-based aramid alternatives are critical factors driving the environmental improvement of these high-performance fabrics.

Choosing the Right Fabric: Kevlar or Aramid?

Kevlar fabric, a specific type of aramid fiber, offers exceptional strength-to-weight ratio and high tensile strength ideal for ballistic and protective applications. Aramid fabric, which includes Kevlar and other variations like Nomex, provides heat resistance and durability, making it suitable for diverse industrial uses beyond just impact protection. Choosing between Kevlar and other aramid fabrics depends on the required balance of performance factors such as tensile strength, thermal resistance, flexibility, and cost-effectiveness for the intended application.

Kevlar fabric vs Aramid fabric Infographic

materialdif.com

materialdif.com