Kevlar belts offer superior flexibility and lighter weight compared to steel belts, making them ideal for applications requiring enhanced durability without added bulk. The high tensile strength of Kevlar fibers provides excellent resistance to wear and tear, while steel belts tend to be more rigid and prone to corrosion over time. Choosing a Kevlar belt improves performance in demanding environments by combining strength with resilience and resistance to environmental factors.

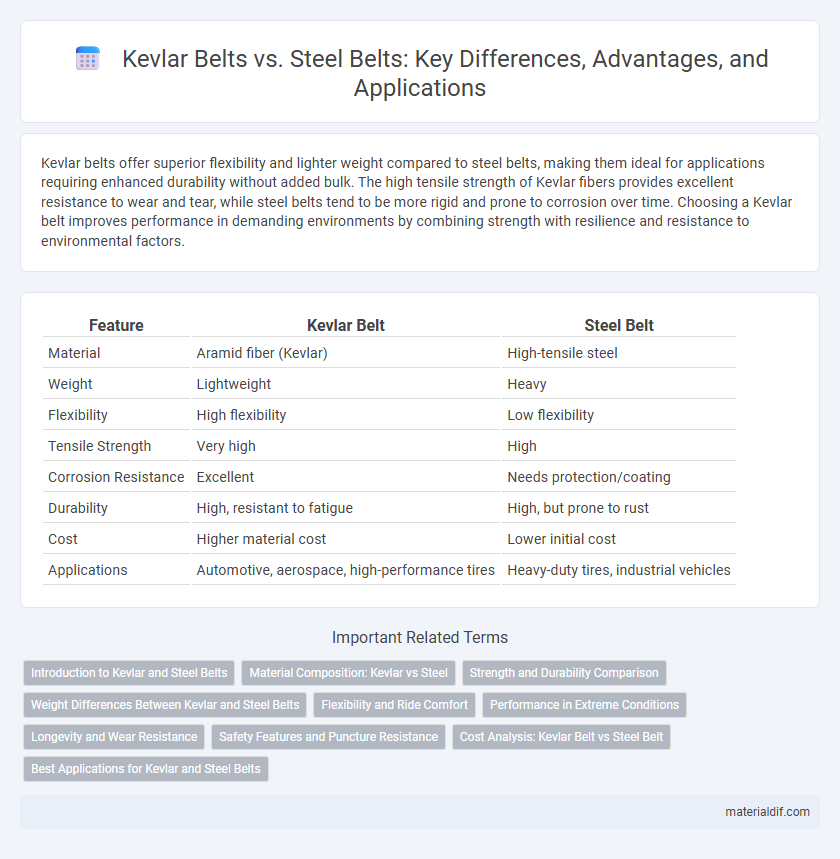

Table of Comparison

| Feature | Kevlar Belt | Steel Belt |

|---|---|---|

| Material | Aramid fiber (Kevlar) | High-tensile steel |

| Weight | Lightweight | Heavy |

| Flexibility | High flexibility | Low flexibility |

| Tensile Strength | Very high | High |

| Corrosion Resistance | Excellent | Needs protection/coating |

| Durability | High, resistant to fatigue | High, but prone to rust |

| Cost | Higher material cost | Lower initial cost |

| Applications | Automotive, aerospace, high-performance tires | Heavy-duty tires, industrial vehicles |

Introduction to Kevlar and Steel Belts

Kevlar belts are made from high-strength aramid fibers known for their lightweight and exceptional tensile strength, offering superior flexibility and resistance to heat and chemicals. Steel belts consist of interlocked steel cables or strips, providing exceptional durability and load-bearing capacity but with added weight and reduced flexibility. Both materials are widely used in industrial applications, with Kevlar favored for lightweight, high-performance tasks and steel belts chosen for heavy-duty, high-stress environments.

Material Composition: Kevlar vs Steel

Kevlar belts are composed of synthetic aramid fibers known for their high tensile strength-to-weight ratio, providing excellent flexibility and resistance to corrosion, unlike steel belts, which are made from high-carbon steel wires offering superior rigidity and durability but increased weight and susceptibility to rust. Kevlar's polymer-based composition allows for enhanced impact resistance and quieter operation, making it ideal for applications requiring lightweight and flexible materials. Steel belts, while heavier and less flexible, excel in environments demanding extreme strength and high-temperature resistance due to their metallic properties.

Strength and Durability Comparison

Kevlar belts exhibit superior tensile strength compared to steel belts, offering enhanced resistance to stretching and impact forces. Kevlar's high strength-to-weight ratio ensures durability while reducing overall belt weight, which improves efficiency in mechanical systems. Steel belts, although durable under heavy loads, are more prone to fatigue and corrosion, limiting their longevity compared to Kevlar's corrosion-resistant and flexible fibers.

Weight Differences Between Kevlar and Steel Belts

Kevlar belts are significantly lighter than steel belts, offering a weight reduction of up to 40-50% in industrial and automotive applications. This weight advantage improves fuel efficiency and handling in vehicles, while reducing overall machinery load and stress. Kevlar's high tensile strength combined with its lightweight properties make it an optimal choice where weight savings and durability are critical.

Flexibility and Ride Comfort

Kevlar belts offer superior flexibility compared to steel belts, allowing tires to better absorb road irregularities and enhance ride comfort. The lightweight nature of Kevlar reduces rotational mass, resulting in improved handling and a smoother driving experience. Steel belts provide strength and durability, but their rigidity can lead to a harsher ride and less responsive tire performance.

Performance in Extreme Conditions

Kevlar belts outperform steel belts in extreme conditions due to their superior heat resistance and flexibility, which prevents cracking and deformation under high temperatures. Kevlar's lightweight nature reduces stress on machinery, enhancing durability and operational efficiency in harsh environments. Unlike steel belts, Kevlar also offers excellent corrosion resistance, ensuring longer service life in wet or chemically aggressive conditions.

Longevity and Wear Resistance

Kevlar belts exhibit superior longevity and wear resistance compared to steel belts due to their high tensile strength and flexibility, which reduce the risk of cracking and fatigue over time. Kevlar fibers offer exceptional resistance to abrasion and heat, extending the belt's operational lifespan in demanding industrial applications. Steel belts, while strong, are prone to corrosion and fatigue, making Kevlar an optimal choice for environments requiring durable, long-lasting belt performance.

Safety Features and Puncture Resistance

Kevlar belts offer superior puncture resistance compared to steel belts due to their high tensile strength and flexibility, effectively absorbing impacts and reducing the risk of tire blowouts. The aramid fiber composition of Kevlar enhances safety by maintaining structural integrity under extreme stress and temperature variations, unlike the rigid steel belts prone to corrosion and fatigue. Kevlar's lightweight nature also contributes to improved vehicle handling and reduced heat buildup, further elevating overall tire safety.

Cost Analysis: Kevlar Belt vs Steel Belt

Kevlar belts offer a significant cost advantage over steel belts due to lower material and manufacturing expenses, as Kevlar fibers are lighter and easier to process. Maintenance costs for Kevlar belts are generally reduced because they resist corrosion and require less frequent replacement compared to steel belts, which are prone to rust and wear. Although the initial price of Kevlar belts can be higher, the overall lifecycle cost is often lower, making Kevlar a more cost-effective option for long-term industrial applications.

Best Applications for Kevlar and Steel Belts

Kevlar belts excel in applications requiring lightweight, high-strength materials with superior flexibility and resistance to heat and corrosion, making them ideal for high-performance automotive tires and aerospace components. Steel belts are best suited for heavy-duty industrial uses where maximum durability, puncture resistance, and load-bearing capacity are critical, such as in truck tires and conveyor belts. Choosing between Kevlar and steel belts depends on balancing factors like weight reduction, flexibility, and strength demands specific to the application.

Kevlar belt vs Steel belt Infographic

materialdif.com

materialdif.com