Kevlar sheets offer superior impact resistance and flexibility compared to carbon fiber sheets, making them ideal for protective pet gear such as harnesses and armor. Carbon fiber sheets provide higher rigidity and stiffness, which suits structural applications but may sacrifice comfort and durability under stress. Choosing between Kevlar and carbon fiber sheets depends on the balance between flexibility, impact absorption, and strength required for pet safety products.

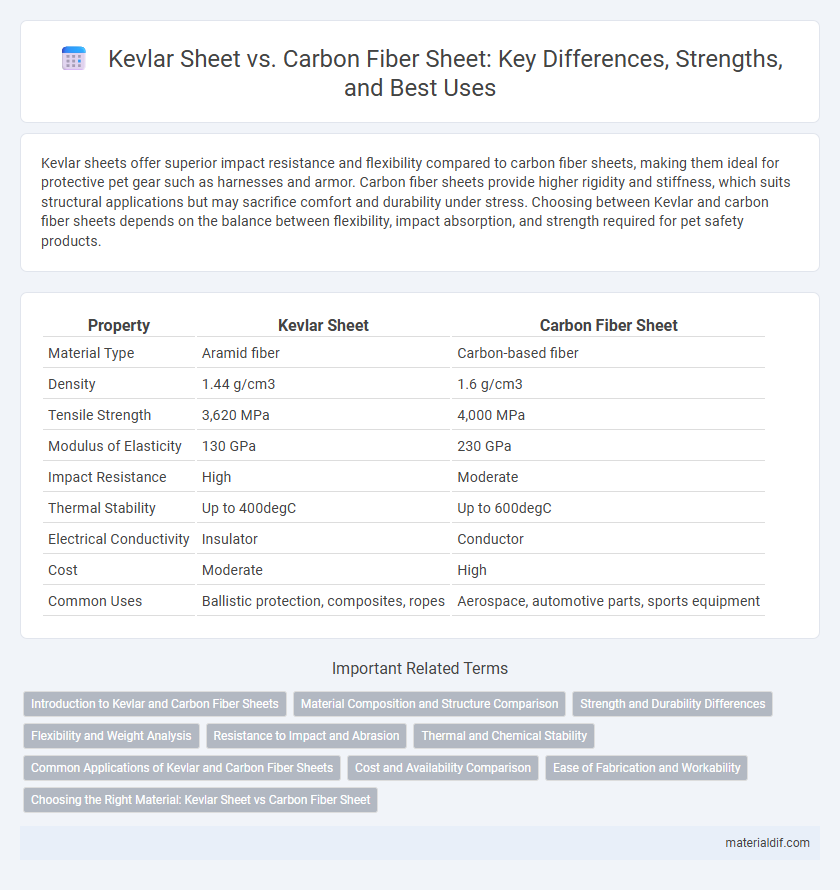

Table of Comparison

| Property | Kevlar Sheet | Carbon Fiber Sheet |

|---|---|---|

| Material Type | Aramid fiber | Carbon-based fiber |

| Density | 1.44 g/cm3 | 1.6 g/cm3 |

| Tensile Strength | 3,620 MPa | 4,000 MPa |

| Modulus of Elasticity | 130 GPa | 230 GPa |

| Impact Resistance | High | Moderate |

| Thermal Stability | Up to 400degC | Up to 600degC |

| Electrical Conductivity | Insulator | Conductor |

| Cost | Moderate | High |

| Common Uses | Ballistic protection, composites, ropes | Aerospace, automotive parts, sports equipment |

Introduction to Kevlar and Carbon Fiber Sheets

Kevlar sheets are made from aramid fibers known for their exceptional tensile strength, impact resistance, and lightweight properties, making them ideal for ballistic protection and reinforcement applications. Carbon fiber sheets consist of tightly woven carbon fibers bonded with resin, offering superior stiffness, high strength-to-weight ratio, and excellent thermal conductivity, commonly used in aerospace, automotive, and sports equipment. Both materials provide advanced performance characteristics, but Kevlar excels in impact absorption while carbon fiber is preferred for rigidity and structural support.

Material Composition and Structure Comparison

Kevlar sheets consist of para-aramid synthetic fibers known for their high tensile strength and exceptional impact resistance, arranged in a tightly woven pattern that enhances flexibility and durability. Carbon fiber sheets are composed of thin strands of carbon atoms bonded in a crystalline structure, providing superior stiffness and a high strength-to-weight ratio with a rigid, brittle nature. The distinct molecular composition and fiber arrangement result in Kevlar offering better toughness and energy absorption, while carbon fiber delivers greater rigidity and compressive strength.

Strength and Durability Differences

Kevlar sheets offer exceptional tensile strength and impact resistance, making them highly durable against punctures and abrasion compared to carbon fiber sheets. Carbon fiber sheets provide superior stiffness and compressive strength but tend to be more brittle under impact, potentially leading to cracks. Kevlar's molecular structure enhances flexibility and energy absorption, resulting in longer-lasting performance in high-stress, dynamic environments.

Flexibility and Weight Analysis

Kevlar sheets offer superior flexibility compared to carbon fiber sheets, making them ideal for applications requiring impact resistance and tensile strength without brittleness. Carbon fiber sheets, while significantly lighter in weight, excel in stiffness and rigidity but tend to be more brittle under flexural stress. The weight-to-flexibility ratio highlights Kevlar's advantage in dynamic environments where durability and shock absorption are critical.

Resistance to Impact and Abrasion

Kevlar sheets exhibit superior resistance to impact due to their high tensile strength and energy-absorbing fibers, making them ideal for applications requiring shock absorption and penetration resistance. Carbon fiber sheets offer excellent abrasion resistance through their hard, rigid surface but can be more brittle under sudden impacts, leading to potential cracking. The choice between Kevlar and carbon fiber sheets depends on the specific need for impact durability or surface wear resistance, with Kevlar favored for impact-heavy environments and carbon fiber for scratch and abrasion endurance.

Thermal and Chemical Stability

Kevlar sheets exhibit exceptional thermal stability with a decomposition temperature above 450degC, maintaining structural integrity under high heat, whereas carbon fiber sheets typically withstand temperatures up to 300-400degC before degradation. Chemically, Kevlar is resistant to many solvents, fuels, and organic chemicals, but vulnerable to strong acids and bases; carbon fiber sheets also resist most chemicals yet can corrode in oxidizing acids. The superior thermal resistance and moderate chemical stability of Kevlar sheets make them ideal for applications requiring prolonged exposure to extreme heat and harsh chemical environments.

Common Applications of Kevlar and Carbon Fiber Sheets

Kevlar sheets are widely used in ballistic protection, body armor, and aerospace applications due to their exceptional impact resistance and lightweight properties. Carbon fiber sheets find common applications in automotive parts, sporting goods, and construction, prized for their high stiffness and strength-to-weight ratio. Both materials are critical in engineering and safety industries, with Kevlar excelling in impact absorption and carbon fiber dominating structural reinforcement.

Cost and Availability Comparison

Kevlar sheets typically cost less than carbon fiber sheets, making them a more budget-friendly option for many applications. Kevlar is widely available through various suppliers due to its extensive use in protective gear and industrial products, whereas carbon fiber sheets can be more limited and expensive owing to their specialized manufacturing process. The cost difference reflects Kevlar's balance of strength and affordability compared to the higher performance but pricier carbon fiber alternatives.

Ease of Fabrication and Workability

Kevlar sheets offer superior flexibility and toughness, making them easier to cut, shape, and bond during fabrication compared to rigid carbon fiber sheets. Unlike carbon fiber, Kevlar's low brittleness reduces the risk of cracking or splintering, enhancing workability in complex or curved designs. Manufacturing with Kevlar requires specialized tools due to its fibrous structure, but overall it provides greater ease in manual handling and assembling than the more brittle and stiff carbon fiber composites.

Choosing the Right Material: Kevlar Sheet vs Carbon Fiber Sheet

Kevlar sheets offer exceptional impact resistance and flexibility, making them ideal for applications requiring high toughness and durability, such as protective gear and ballistic armor. Carbon fiber sheets provide superior stiffness and tensile strength with a lightweight profile, often favored in aerospace, automotive, and sporting goods for enhanced structural performance. Selecting between Kevlar and carbon fiber sheets depends on the specific demands of the project, balancing factors like impact resistance, rigidity, weight, and environmental conditions.

Kevlar sheet vs Carbon fiber sheet Infographic

materialdif.com

materialdif.com