Kevlar aramid is a general term for a strong synthetic fiber used in various protective applications, while Kevlar para-aramid specifically refers to fibers with molecules aligned parallel to the fiber axis, providing superior tensile strength and durability. In pet products, Kevlar para-aramid offers enhanced resistance to tears and abrasions, making it ideal for high-strength collars, harnesses, and leashes. This specialized form of Kevlar ensures pet gear remains reliable and long-lasting under tough conditions.

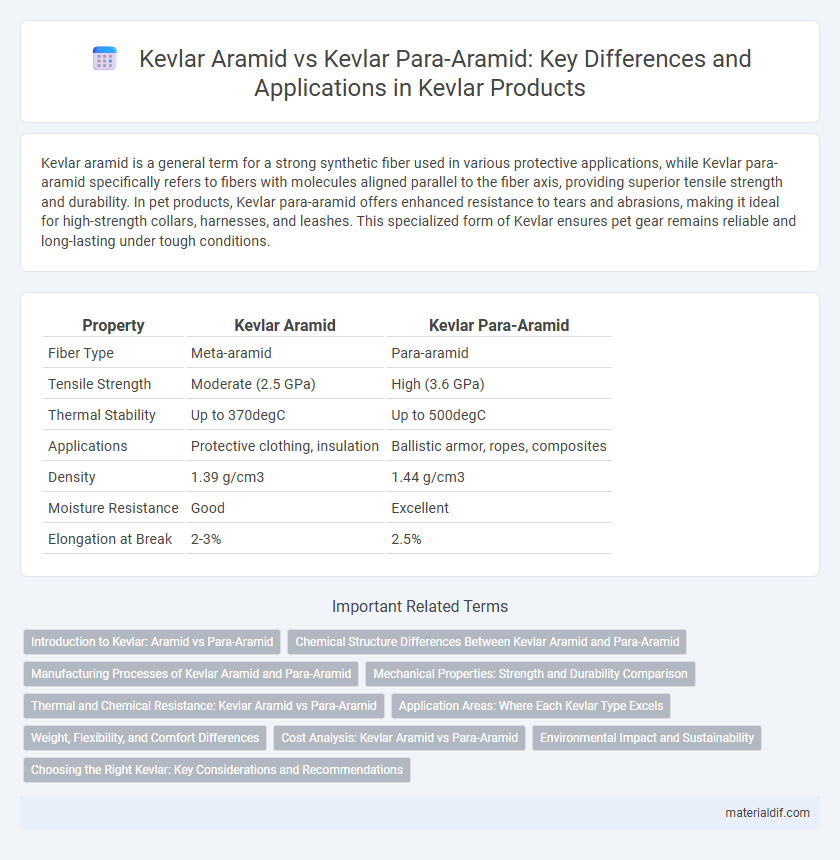

Table of Comparison

| Property | Kevlar Aramid | Kevlar Para-Aramid |

|---|---|---|

| Fiber Type | Meta-aramid | Para-aramid |

| Tensile Strength | Moderate (2.5 GPa) | High (3.6 GPa) |

| Thermal Stability | Up to 370degC | Up to 500degC |

| Applications | Protective clothing, insulation | Ballistic armor, ropes, composites |

| Density | 1.39 g/cm3 | 1.44 g/cm3 |

| Moisture Resistance | Good | Excellent |

| Elongation at Break | 2-3% | 2.5% |

Introduction to Kevlar: Aramid vs Para-Aramid

Kevlar is a high-performance synthetic fiber classified as an aramid, renowned for its exceptional strength and heat resistance. The distinction between aramid and para-aramid lies in their molecular alignment; Kevlar para-aramid features linear polymer chains oriented parallel to the fiber axis, resulting in enhanced tensile strength and durability. This specific para-aramid structure makes Kevlar ideal for applications such as body armor, aerospace components, and ballistic protection materials.

Chemical Structure Differences Between Kevlar Aramid and Para-Aramid

Kevlar aramid and para-aramid both belong to the aramid family, but their chemical structures differ in polymer chain orientation and bonding patterns. Kevlar aramid features para-oriented aromatic polyamides with rigid linear chains that result in high tensile strength and thermal stability. This para-aramid structure contrasts with meta-aramids, where the polymer chains have a kinked arrangement, influencing flexibility and impact resistance.

Manufacturing Processes of Kevlar Aramid and Para-Aramid

Kevlar aramid and Kevlar para-aramid differ primarily in their molecular structure, which influences their manufacturing processes. Kevlar aramid fibers are produced through a polycondensation reaction of aromatic diamines and terephthaloyl chloride, with the para orientation enabling high tensile strength and thermal stability. The controlled spinning and heat treatment processes for para-aramid result in fibers with superior stiffness and impact resistance, making them ideal for ballistic and aerospace applications.

Mechanical Properties: Strength and Durability Comparison

Kevlar para-aramid fibers exhibit superior tensile strength and enhanced durability compared to standard Kevlar aramid, making them ideal for high-performance applications such as body armor and aerospace components. The molecular alignment in Kevlar para-aramid provides greater resistance to abrasion and impact, resulting in longer-lasting material performance under extreme conditions. Mechanical testing consistently shows para-aramid variants maintain structural integrity and strength retention better than generic aramid fibers over prolonged use.

Thermal and Chemical Resistance: Kevlar Aramid vs Para-Aramid

Kevlar para-aramid exhibits superior thermal resistance with a decomposition temperature above 450degC, while Kevlar aramid typically withstands temperatures around 425degC. Chemically, para-aramid fibers demonstrate enhanced resistance to organic solvents and abrasion compared to meta-aramid fibers, making Kevlar para-aramid more suitable for high-performance protective applications. Both variants resist weak acids and alkalis, but para-aramid retains structural integrity better under prolonged chemical exposure.

Application Areas: Where Each Kevlar Type Excels

Kevlar aramid fibers exhibit exceptional strength and thermal stability, making them ideal for aerospace engineering and automotive components requiring high durability and heat resistance. Kevlar para-aramid fibers, characterized by their superior tensile strength and low stretch, excel in ballistic protection such as bulletproof vests and helmets, as well as in industrial materials like ropes and cables. The choice between Kevlar aramid and Kevlar para-aramid depends on specific application demands, with para-aramid favored for impact resistance and aramid suited for high-temperature environments.

Weight, Flexibility, and Comfort Differences

Kevlar para-aramid fibers offer superior strength-to-weight ratio compared to standard Kevlar aramid, making them lighter and more suitable for applications requiring high durability with minimal weight. The para-aramid structure provides enhanced flexibility, allowing for better mobility and reduced stiffness in protective gear. In terms of comfort, para-aramid materials generally exhibit improved breathability and softness, contributing to greater wearer comfort during extended use.

Cost Analysis: Kevlar Aramid vs Para-Aramid

Kevlar para-aramid fibers typically exhibit higher cost efficiency due to superior tensile strength and thermal resistance compared to traditional Kevlar aramid fibers, resulting in longer service life and reduced replacement expenses. The manufacturing complexity of para-aramid fibers contributes to a premium price point, but enhanced durability and performance in protective gear often justify the initial investment. Cost analysis must consider the balance between upfront expenses and long-term operational savings derived from improved material properties.

Environmental Impact and Sustainability

Kevlar para-aramid exhibits a more favorable environmental profile compared to traditional Kevlar aramid due to its higher durability and longer lifespan, which reduce the frequency of replacement and waste generation. The production process of para-aramid fibers is increasingly optimized for energy efficiency and reduced chemical usage, contributing to lower carbon emissions and less environmental pollution. Recycling initiatives for para-aramid materials are advancing, further enhancing sustainability by minimizing landfill contributions and promoting circular economy practices in high-performance fiber applications.

Choosing the Right Kevlar: Key Considerations and Recommendations

Kevlar para-aramid fibers exhibit superior tensile strength and thermal resistance compared to standard Kevlar aramid, making them ideal for high-performance ballistic and protective applications. When choosing Kevlar, consider the application's demand for durability, weight, and environmental exposure, as para-aramid offers enhanced heat resistance and impact absorption. For industrial and safety gear, selecting Kevlar para-aramid ensures maximum protection efficiency, while standard Kevlar aramid suits less extreme environments where flexibility and cost-efficiency are priorities.

Kevlar aramid vs Kevlar para-aramid Infographic

materialdif.com

materialdif.com