E-glass and Kevlar are two popular materials used in pet products for their strength and durability. Kevlar offers superior impact resistance and flexibility, making it ideal for pet gear exposed to rough use or bites. E-glass provides good tensile strength and is more cost-effective but is less resistant to abrasion and impact compared to Kevlar.

Table of Comparison

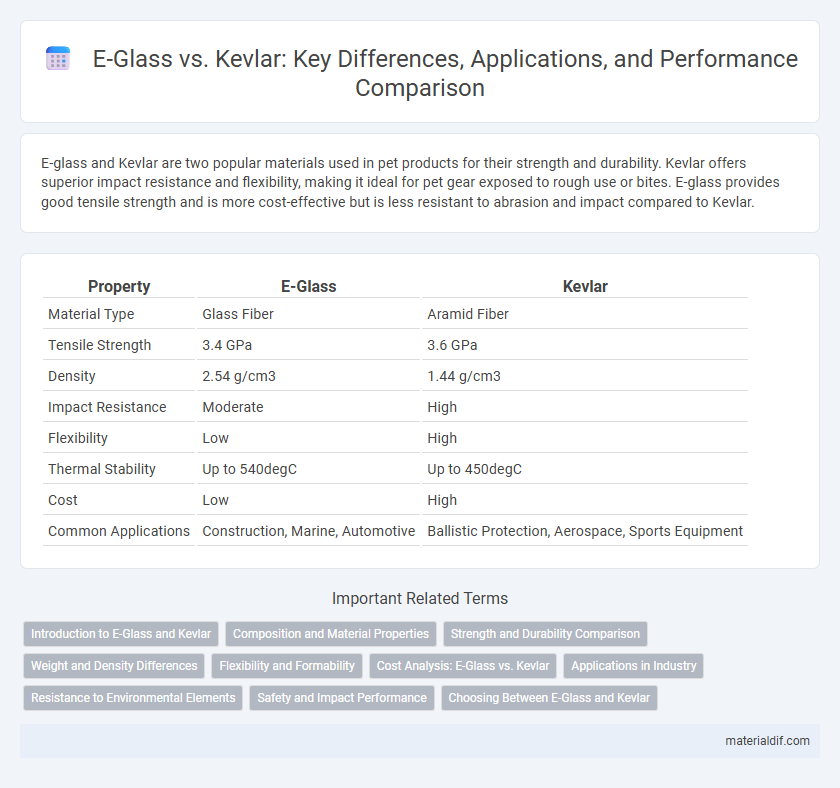

| Property | E-Glass | Kevlar |

|---|---|---|

| Material Type | Glass Fiber | Aramid Fiber |

| Tensile Strength | 3.4 GPa | 3.6 GPa |

| Density | 2.54 g/cm3 | 1.44 g/cm3 |

| Impact Resistance | Moderate | High |

| Flexibility | Low | High |

| Thermal Stability | Up to 540degC | Up to 450degC |

| Cost | Low | High |

| Common Applications | Construction, Marine, Automotive | Ballistic Protection, Aerospace, Sports Equipment |

Introduction to E-Glass and Kevlar

E-glass is a type of fiberglass characterized by its electrical insulation properties and high tensile strength, commonly used in composite materials for aerospace and automotive applications. Kevlar, a para-aramid synthetic fiber, offers exceptional impact resistance and superior tensile strength, making it ideal for ballistic protection and high-performance composites. Both materials serve distinct roles in engineering, with E-glass favored for cost-effectiveness and electrical insulation, while Kevlar excels in durability and lightweight protection.

Composition and Material Properties

E-glass is primarily composed of alumino-borosilicate glass fibers known for high tensile strength and electrical insulation, while Kevlar is an aramid fiber made of poly-paraphenylene terephthalamide offering exceptional impact resistance and tensile strength. Kevlar's molecular structure provides superior toughness and energy absorption compared to the brittle nature of E-glass fibers. Both materials are used in composites, but Kevlar excels in applications requiring high durability and lightweight protection.

Strength and Durability Comparison

Kevlar exhibits superior tensile strength compared to E-glass, making it more effective in applications requiring high impact resistance and durability. While E-glass offers good tensile strength and stiffness, Kevlar's unique molecular structure provides greater toughness and resilience against fatigue and abrasion. Kevlar's enhanced durability under stress makes it the preferred choice in protective gear, aerospace, and military applications where consistent performance under extreme conditions is critical.

Weight and Density Differences

E-glass has a density of approximately 2.55 g/cm3, making it significantly heavier than Kevlar, which has a density around 1.44 g/cm3. The lower density of Kevlar contributes to lighter composite materials, enhancing its suitability for applications requiring high strength-to-weight ratios, such as aerospace and ballistic protection. Weight advantages of Kevlar improve fuel efficiency and performance compared to E-glass in these critical uses.

Flexibility and Formability

Kevlar exhibits superior flexibility and formability compared to E-glass due to its high tensile strength and toughness, enabling it to bend and conform to complex shapes without cracking. E-glass is stiffer and more brittle, limiting its ability to be molded into intricate forms without damage. This makes Kevlar ideal for applications requiring lightweight, durable materials that maintain structural integrity under dynamic bending and shaping conditions.

Cost Analysis: E-Glass vs. Kevlar

E-glass offers a significantly lower cost compared to Kevlar, making it a preferred choice for projects with tight budget constraints. Kevlar's higher price reflects its superior tensile strength, impact resistance, and durability in demanding applications. When evaluating cost-effectiveness, E-glass provides affordability while Kevlar delivers enhanced performance benefits justifying its investment in advanced composite materials.

Applications in Industry

E-glass fibers are extensively used in automotive, marine, and construction industries due to their excellent tensile strength, corrosion resistance, and cost-efficiency. Kevlar, known for its high impact resistance and lightweight properties, is preferred in aerospace, military armor, and sports equipment manufacturing to enhance durability and safety. Industrial applications prioritize E-glass for structural reinforcement, while Kevlar is favored for protective gear and high-performance composites.

Resistance to Environmental Elements

Kevlar exhibits superior resistance to environmental elements compared to E-glass, maintaining its structural integrity under prolonged exposure to UV radiation and moisture. While E-glass fibers are prone to degradation and reduced mechanical performance when exposed to harsh conditions, Kevlar's aramid fibers provide enhanced durability and longevity in outdoor and marine applications. This makes Kevlar a preferred choice for environments demanding high resistance to chemicals, temperature fluctuations, and weathering effects.

Safety and Impact Performance

Kevlar outperforms E-glass in safety and impact performance due to its superior tensile strength and energy absorption capacity, making it ideal for ballistic protection and personal armor. E-glass fibers, while cost-effective and strong in tension, lack the toughness and resilience needed to withstand high-velocity impacts without fracturing. Kevlar's molecular structure allows it to deform and dissipate impact forces efficiently, reducing penetration risk and enhancing wearer safety in hazardous environments.

Choosing Between E-Glass and Kevlar

Choosing between E-glass and Kevlar depends on the specific application requirements such as strength, weight, and cost considerations. E-glass offers excellent tensile strength and chemical resistance at a lower cost, making it suitable for general-purpose composites and insulation materials. Kevlar provides superior impact resistance and higher tensile strength-to-weight ratio, ideal for ballistic protection, aerospace, and high-performance sporting goods.

E-glass vs Kevlar Infographic

materialdif.com

materialdif.com