Kevlar aramid offers exceptional impact resistance and durability, making it ideal for protective pet gear such as harnesses and vests that withstand rough use. Kevlar carbon hybrid combines the toughness of aramid fibers with the lightweight strength and stiffness of carbon fibers, resulting in pet products that are both durable and highly lightweight. Choosing between the two depends on the need for flexibility and abrasion resistance from aramid or enhanced rigidity and reduced weight from the carbon hybrid.

Table of Comparison

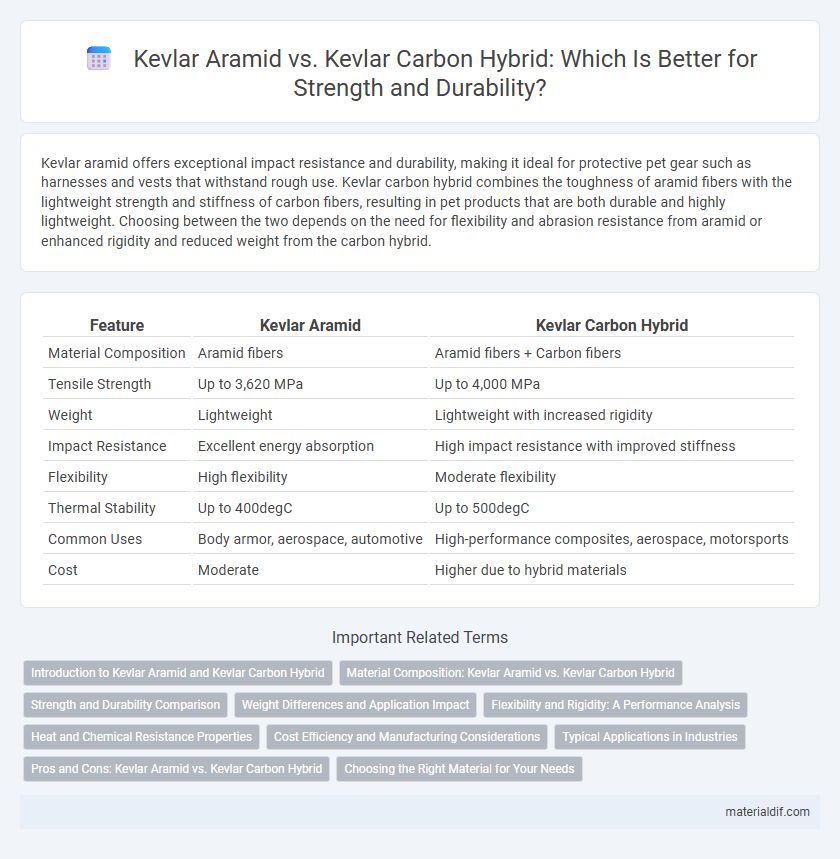

| Feature | Kevlar Aramid | Kevlar Carbon Hybrid |

|---|---|---|

| Material Composition | Aramid fibers | Aramid fibers + Carbon fibers |

| Tensile Strength | Up to 3,620 MPa | Up to 4,000 MPa |

| Weight | Lightweight | Lightweight with increased rigidity |

| Impact Resistance | Excellent energy absorption | High impact resistance with improved stiffness |

| Flexibility | High flexibility | Moderate flexibility |

| Thermal Stability | Up to 400degC | Up to 500degC |

| Common Uses | Body armor, aerospace, automotive | High-performance composites, aerospace, motorsports |

| Cost | Moderate | Higher due to hybrid materials |

Introduction to Kevlar Aramid and Kevlar Carbon Hybrid

Kevlar aramid is a high-strength synthetic fiber known for its exceptional durability, impact resistance, and lightweight properties, commonly used in body armor, aerospace, and automotive applications. Kevlar carbon hybrid combines the toughness of Kevlar aramid with the stiffness and lightweight characteristics of carbon fiber, enhancing structural performance and energy absorption in composite materials. This hybrid material optimizes strength-to-weight ratio, making it ideal for advanced protective gear and high-performance sporting equipment.

Material Composition: Kevlar Aramid vs. Kevlar Carbon Hybrid

Kevlar aramid is a synthetic fiber composed primarily of poly-paraphenylene terephthalamide, known for its exceptional tensile strength and impact resistance. Kevlar carbon hybrid combines aramid fibers with carbon fibers, enhancing stiffness and thermal stability while maintaining lightweight durability. The hybrid material offers a superior strength-to-weight ratio compared to pure Kevlar aramid, making it ideal for high-performance applications requiring both flexibility and rigidity.

Strength and Durability Comparison

Kevlar aramid fibers provide exceptional tensile strength and impact resistance, making them highly durable under stress and abrasion. Kevlar carbon hybrids combine the lightweight stiffness and high modulus of carbon fibers with the toughness of aramid, resulting in improved strength-to-weight ratios and enhanced overall durability. This hybrid construction offers superior performance in applications requiring both flexibility and rigidity, outperforming pure Kevlar aramid in resistance to fatigue and environmental degradation.

Weight Differences and Application Impact

Kevlar aramid fibers offer high tensile strength and excellent impact resistance at a low weight, making them ideal for lightweight body armor and protective gear. Kevlar carbon hybrids combine aramid fibers with carbon fibers, resulting in a material with increased stiffness and reduced weight compared to pure Kevlar aramid, which enhances performance in aerospace and automotive applications requiring both strength and rigidity. The weight differences between Kevlar aramid and Kevlar carbon hybrids directly influence their suitability for applications, with hybrids favored where weight savings and structural integrity are critical.

Flexibility and Rigidity: A Performance Analysis

Kevlar aramid fibers provide exceptional flexibility and impact resistance, making them ideal for applications requiring durability and lightweight protection. In contrast, Kevlar carbon hybrids combine the toughness of aramid with the stiffness of carbon fibers, resulting in increased rigidity and structural strength without significantly compromising flexibility. This hybrid composition enhances performance in industries such as aerospace and automotive, where both flexibility and rigidity are critical for safety and efficiency.

Heat and Chemical Resistance Properties

Kevlar aramid fibers exhibit exceptional heat resistance, maintaining structural integrity at temperatures up to 450degC, making them ideal for high-temperature protective applications. In contrast, Kevlar carbon hybrids combine the thermal stability of carbon fibers with Kevlar's inherent chemical resistance, enhancing durability against corrosive substances and thermal degradation. The synergy in hybrids offers balanced heat resistance around 600degC along with improved chemical resistance to acids, solvents, and alkalis, outperforming pure Kevlar aramid in harsh environments.

Cost Efficiency and Manufacturing Considerations

Kevlar aramid fibers offer superior impact resistance and are generally more cost-effective for mass production due to established manufacturing processes and lower raw material expenses. Kevlar carbon hybrids combine the tensile strength and stiffness of carbon fibers with the toughness of Kevlar, resulting in enhanced mechanical performance but higher material costs and more complex fabrication techniques. Manufacturers must balance these factors, as hybrids entail increased production times and tooling requirements, impacting overall cost efficiency compared to pure Kevlar aramid composites.

Typical Applications in Industries

Kevlar aramid fibers are widely used in personal protective equipment, automotive components, and aerospace structures due to their high tensile strength and impact resistance. Kevlar carbon hybrids combine the lightweight stiffness of carbon with Kevlar's toughness, making them ideal for high-performance sporting goods, advanced aerospace parts, and military applications. These hybrids enhance durability and weight savings, optimizing performance in sectors requiring both flexibility and structural integrity.

Pros and Cons: Kevlar Aramid vs. Kevlar Carbon Hybrid

Kevlar aramid offers exceptional impact resistance, lightweight strength, and flexibility ideal for ballistic protection and abrasion resistance, but lacks the rigidity and compressive strength found in carbon composites. Kevlar carbon hybrid composites combine Kevlar's toughness with carbon fiber's high stiffness and excellent tensile strength, resulting in materials that are lighter and more durable under mechanical loads but can be more brittle and costly. Choosing between Kevlar aramid and Kevlar carbon hybrids depends on specific application requirements such as flexibility, weight constraints, and structural performance.

Choosing the Right Material for Your Needs

Kevlar aramid fibers offer exceptional impact resistance and flexibility, making them ideal for ballistic protection and personal armor applications. Kevlar carbon hybrids combine the lightweight strength of carbon fiber with Kevlar's toughness, providing enhanced rigidity and durability suited for high-performance composites in aerospace and automotive industries. Selecting between Kevlar aramid and Kevlar carbon hybrid depends on specific requirements such as weight, strength, flexibility, and environmental resistance.

Kevlar aramid vs Kevlar carbon hybrid Infographic

materialdif.com

materialdif.com