Kevlar rope offers superior strength and resistance to abrasion compared to nylon rope, making it ideal for heavy-duty pet applications such as harnesses and leads. Unlike nylon, Kevlar maintains its integrity under extreme heat and UV exposure, ensuring enhanced durability and safety for active pets. While nylon rope is more elastic and affordable, Kevlar's minimal stretch and exceptional toughness provide reliable performance in demanding environments.

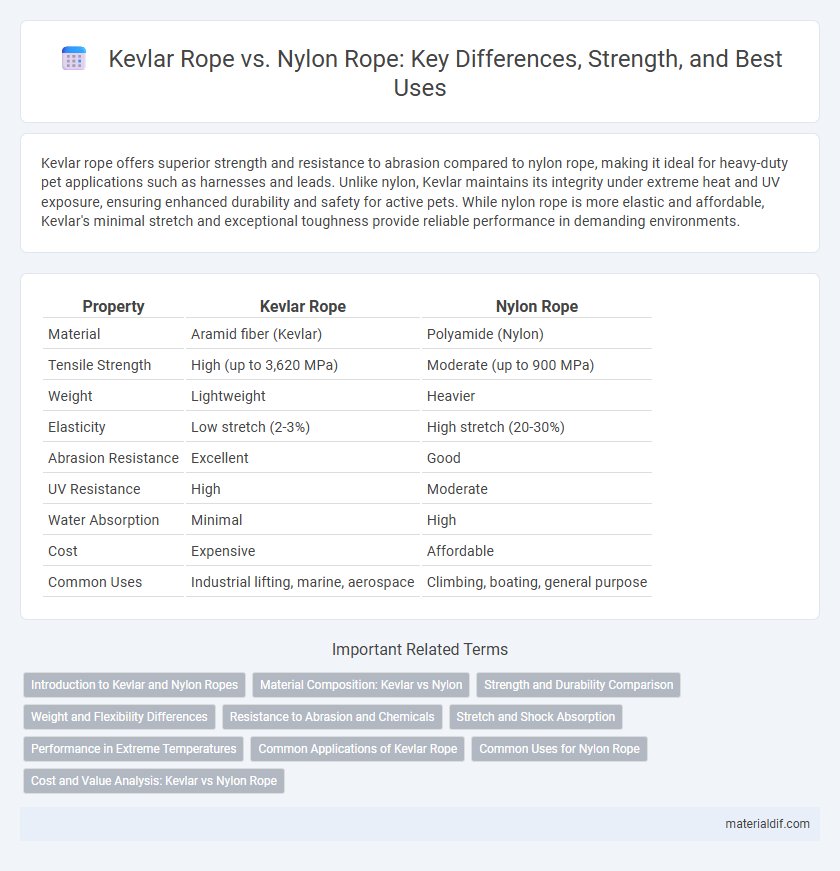

Table of Comparison

| Property | Kevlar Rope | Nylon Rope |

|---|---|---|

| Material | Aramid fiber (Kevlar) | Polyamide (Nylon) |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 900 MPa) |

| Weight | Lightweight | Heavier |

| Elasticity | Low stretch (2-3%) | High stretch (20-30%) |

| Abrasion Resistance | Excellent | Good |

| UV Resistance | High | Moderate |

| Water Absorption | Minimal | High |

| Cost | Expensive | Affordable |

| Common Uses | Industrial lifting, marine, aerospace | Climbing, boating, general purpose |

Introduction to Kevlar and Nylon Ropes

Kevlar rope is composed of aramid fibers renowned for their exceptional tensile strength, heat resistance, and low stretch properties, making it ideal for heavy-duty applications requiring durability and safety. Nylon rope, made from synthetic polyamide fibers, offers excellent elasticity, abrasion resistance, and shock absorption, commonly used in climbing, marine, and general-purpose use. Compared to nylon, Kevlar rope provides superior strength-to-weight ratio and thermal stability but lacks the flexibility and elasticity typical of nylon fibers.

Material Composition: Kevlar vs Nylon

Kevlar rope is made from aramid fibers known for exceptional tensile strength and heat resistance, making it ideal for high-performance applications. Nylon rope, composed of polyamide fibers, offers superior elasticity and durability but has lower heat resistance compared to Kevlar. The material composition difference results in Kevlar ropes being stronger and more heat-resistant, while nylon ropes provide better shock absorption and flexibility.

Strength and Durability Comparison

Kevlar rope exhibits superior tensile strength compared to nylon rope, making it ideal for heavy-duty applications requiring maximum load capacity. Its resistance to abrasion, heat, and chemical exposure ensures long-lasting durability in harsh environments, whereas nylon rope tends to degrade faster under similar conditions. Kevlar's minimal stretch under load enhances performance and reliability, contrasting with nylon's higher elasticity.

Weight and Flexibility Differences

Kevlar rope is significantly lighter than nylon rope, with a density of approximately 1.44 g/cm3 compared to nylon's 1.15 g/cm3, providing superior strength-to-weight ratio. Kevlar exhibits less stretch and superior abrasion resistance, making it ideal for applications requiring minimal elongation and high durability, while nylon rope offers greater flexibility and elasticity. The stiffness of Kevlar can reduce knot-holding ability, whereas nylon's flexibility allows easier handling and knot security in various practical uses.

Resistance to Abrasion and Chemicals

Kevlar rope offers superior resistance to abrasion compared to Nylon rope, making it ideal for harsh environments where wear and tear are frequent. Chemically, Kevlar exhibits excellent resistance to a wide range of solvents and oils, while Nylon is more susceptible to degradation from certain acids and alkalis. These properties make Kevlar rope highly durable and reliable for industrial applications requiring long-lasting performance.

Stretch and Shock Absorption

Kevlar rope exhibits minimal stretch, typically less than 2%, providing exceptional dimensional stability under load compared to nylon rope, which can stretch up to 30%. This low stretch characteristic allows Kevlar ropes to maintain consistent tension and reduce dynamic shock, making them ideal for critical applications requiring precise control. Nylon ropes excel in shock absorption due to their elasticity, effectively dampening sudden forces, but this comes at the cost of increased elongation and potential loss of control under high loads.

Performance in Extreme Temperatures

Kevlar rope outperforms nylon rope in extreme temperatures due to its high thermal resistance and stability, maintaining strength and flexibility in both very hot and cold environments. Nylon tends to lose strength and elasticity when exposed to extreme heat, often weakening and degrading faster under such conditions. Kevlar's superior thermal endurance makes it the preferred choice for applications requiring reliable performance in harsh temperature fluctuations.

Common Applications of Kevlar Rope

Kevlar rope is widely used in applications requiring high tensile strength, such as climbing, sailing, and industrial lifting due to its exceptional resistance to abrasion and heat. Unlike nylon ropes, Kevlar ropes maintain durability and shape under extreme stress and harsh environmental conditions, making them ideal for aerospace, military, and marine operations. Their low stretch characteristics and lightweight nature enhance safety and performance in critical scenarios where rope reliability is paramount.

Common Uses for Nylon Rope

Nylon rope is widely used in marine environments, towing, and climbing due to its superior elasticity, shock absorption, and resistance to abrasion. It excels in applications requiring flexibility and strength under dynamic loads. Unlike Kevlar rope, which is preferred for its high tensile strength and heat resistance, nylon rope is favored for everyday tasks where stretch and durability against impact are essential.

Cost and Value Analysis: Kevlar vs Nylon Rope

Kevlar rope generally commands a higher price than nylon rope due to its superior strength-to-weight ratio and durability, offering better long-term value in demanding applications. Nylon rope, while more affordable upfront, tends to stretch and degrade faster, leading to more frequent replacements and higher lifecycle costs. Evaluating total cost of ownership reveals that Kevlar ropes provide cost-efficiency for critical uses where performance and longevity outweigh initial expenditure.

Kevlar rope vs Nylon rope Infographic

materialdif.com

materialdif.com