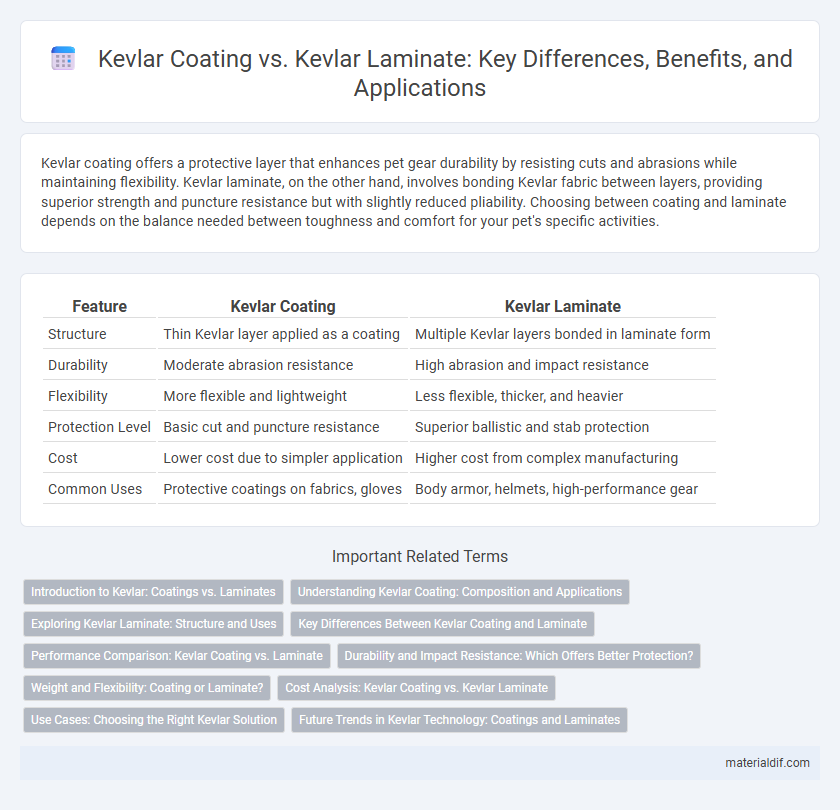

Kevlar coating offers a protective layer that enhances pet gear durability by resisting cuts and abrasions while maintaining flexibility. Kevlar laminate, on the other hand, involves bonding Kevlar fabric between layers, providing superior strength and puncture resistance but with slightly reduced pliability. Choosing between coating and laminate depends on the balance needed between toughness and comfort for your pet's specific activities.

Table of Comparison

| Feature | Kevlar Coating | Kevlar Laminate |

|---|---|---|

| Structure | Thin Kevlar layer applied as a coating | Multiple Kevlar layers bonded in laminate form |

| Durability | Moderate abrasion resistance | High abrasion and impact resistance |

| Flexibility | More flexible and lightweight | Less flexible, thicker, and heavier |

| Protection Level | Basic cut and puncture resistance | Superior ballistic and stab protection |

| Cost | Lower cost due to simpler application | Higher cost from complex manufacturing |

| Common Uses | Protective coatings on fabrics, gloves | Body armor, helmets, high-performance gear |

Introduction to Kevlar: Coatings vs. Laminates

Kevlar coatings provide a thin, protective layer that enhances abrasion resistance and adds durability to surfaces without significantly increasing weight. Kevlar laminates consist of multiple layers of Kevlar fabric bonded together, offering superior impact resistance and structural strength for ballistic and protective applications. Choosing between Kevlar coating and laminate depends on the balance of flexibility, weight, and protection required in specific industrial or defense uses.

Understanding Kevlar Coating: Composition and Applications

Kevlar coating consists of a protective polymer layer applied directly onto Kevlar fibers to enhance durability, chemical resistance, and abrasion protection, making it ideal for applications like ballistic vests and industrial gloves. Kevlar laminate, by contrast, involves bonding multiple layers of Kevlar fabric with resin or adhesive films to form a composite material that offers superior structural strength and impact resistance for aerospace and automotive uses. Understanding the chemical composition of Kevlar coating, primarily polyurethane or silicone-based polymers, reveals its critical role in extending the lifespan and performance of Kevlar-based protective gear.

Exploring Kevlar Laminate: Structure and Uses

Kevlar laminate consists of multiple layers of Kevlar fabric bonded with resin to form a rigid, lightweight composite known for its exceptional tensile strength and impact resistance. This layered structure enhances durability and is commonly used in ballistic armor, aerospace components, and high-performance sporting goods where structural integrity is crucial. The laminate's ability to distribute force over a larger area makes it more effective than coating in applications requiring robust protection and stiffness.

Key Differences Between Kevlar Coating and Laminate

Kevlar coating involves applying a thin layer of Kevlar fibers onto a substrate to enhance surface durability and abrasion resistance, while Kevlar laminate consists of multiple layers of Kevlar fabric bonded together to provide superior structural strength and impact protection. Coatings are typically thinner, lighter, and more flexible, making them suitable for lightweight protective applications, whereas laminates offer enhanced ballistic resistance and rigidity for more demanding safety requirements. The manufacturing process of coatings emphasizes uniform dispersion of fibers, whereas laminates require careful layering and curing to achieve optimal mechanical properties.

Performance Comparison: Kevlar Coating vs. Laminate

Kevlar coating offers enhanced abrasion resistance and flexibility by forming a protective layer directly bonded to surfaces, making it ideal for applications requiring impact absorption and lightweight protection. Kevlar laminate, constructed through multiple bonded layers, provides superior ballistic resistance and structural strength, frequently utilized in body armor and cut-resistant materials. Performance differences hinge on application demands, where coatings excel in durability and flexibility, and laminates deliver higher tensile strength and penetration resistance.

Durability and Impact Resistance: Which Offers Better Protection?

Kevlar laminate provides superior durability and impact resistance compared to Kevlar coating due to its multi-layered structure that effectively absorbs and disperses energy upon impact. The bonding process in Kevlar laminates enhances structural integrity, making it ideal for high-performance protective gear such as ballistic armor. Kevlar coatings, while offering surface protection against abrasions and environmental factors, do not match the comprehensive impact resilience found in laminate applications.

Weight and Flexibility: Coating or Laminate?

Kevlar coating offers a lighter-weight solution by applying a thin protective layer directly onto fabrics, enhancing flexibility without significantly increasing mass. Kevlar laminate, composed of multiple bonded layers, provides superior ballistic resistance but adds more weight and reduces flexibility compared to coatings. Choosing between coating and laminate depends on the balance needed between minimal weight and maximum protection for specific applications.

Cost Analysis: Kevlar Coating vs. Kevlar Laminate

Kevlar coating typically offers a lower upfront cost compared to Kevlar laminate due to reduced material usage and simplified application processes. Kevlar laminate, while more expensive initially, provides enhanced durability and higher resistance to abrasion and impact, potentially lowering long-term maintenance and replacement expenses. Cost analysis should consider total lifecycle expenses where Kevlar laminate's improved performance may justify its premium over Kevlar coating in high-stress applications.

Use Cases: Choosing the Right Kevlar Solution

Kevlar coating offers enhanced abrasion resistance and flexibility, making it ideal for protective clothing and gear exposed to dynamic wear. Kevlar laminate provides superior impact protection and structural strength, suited for ballistic armor and vehicle armor applications. Selecting between Kevlar coating and laminate depends on whether flexibility or maximum protection is the priority in specific use cases.

Future Trends in Kevlar Technology: Coatings and Laminates

Future trends in Kevlar technology highlight significant advancements in both Kevlar coatings and laminates, enhancing durability, flexibility, and lightweight protection. Innovations in nanotechnology and polymer composites are driving the development of next-generation Kevlar coatings that improve abrasion resistance and chemical stability, while laminated Kevlar structures are being optimized for superior impact absorption and multi-layer integration in aerospace and defense applications. Research focuses on eco-friendly processes and hybrid materials that combine Kevlar with carbon fiber or graphene to achieve unprecedented performance in safety gear and ballistic protection.

Kevlar coating vs Kevlar laminate Infographic

materialdif.com

materialdif.com