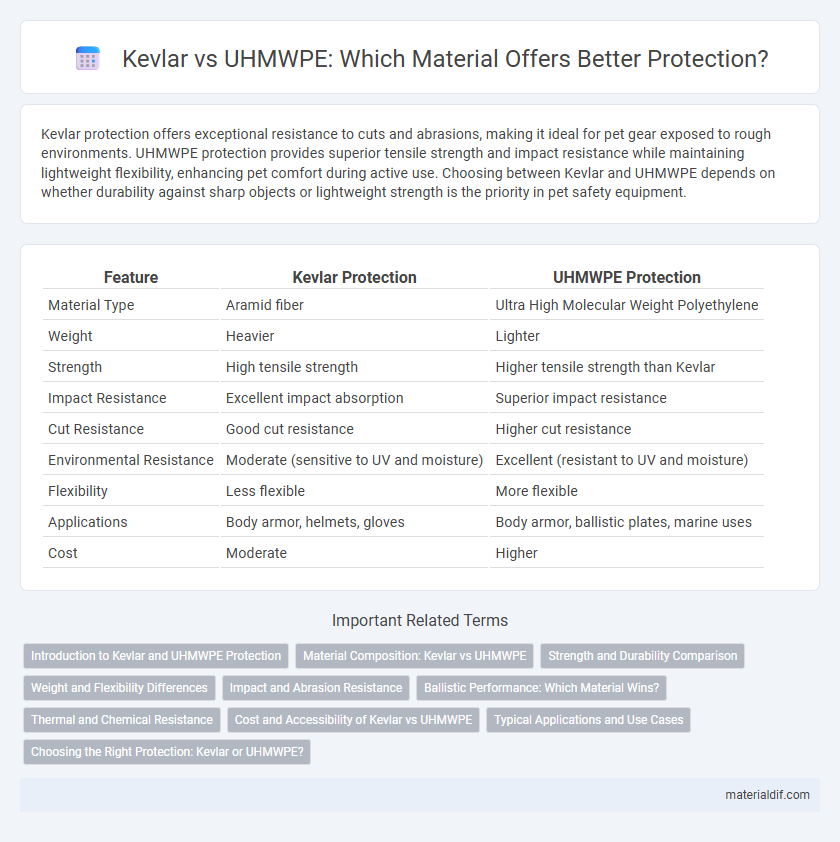

Kevlar protection offers exceptional resistance to cuts and abrasions, making it ideal for pet gear exposed to rough environments. UHMWPE protection provides superior tensile strength and impact resistance while maintaining lightweight flexibility, enhancing pet comfort during active use. Choosing between Kevlar and UHMWPE depends on whether durability against sharp objects or lightweight strength is the priority in pet safety equipment.

Table of Comparison

| Feature | Kevlar Protection | UHMWPE Protection |

|---|---|---|

| Material Type | Aramid fiber | Ultra High Molecular Weight Polyethylene |

| Weight | Heavier | Lighter |

| Strength | High tensile strength | Higher tensile strength than Kevlar |

| Impact Resistance | Excellent impact absorption | Superior impact resistance |

| Cut Resistance | Good cut resistance | Higher cut resistance |

| Environmental Resistance | Moderate (sensitive to UV and moisture) | Excellent (resistant to UV and moisture) |

| Flexibility | Less flexible | More flexible |

| Applications | Body armor, helmets, gloves | Body armor, ballistic plates, marine uses |

| Cost | Moderate | Higher |

Introduction to Kevlar and UHMWPE Protection

Kevlar and UHMWPE are advanced materials widely used for ballistic and impact protection due to their exceptional strength-to-weight ratios. Kevlar, a para-aramid synthetic fiber, offers high tensile strength and thermal stability, making it ideal for lightweight body armor and helmets. UHMWPE, or ultra-high-molecular-weight polyethylene, provides superior energy absorption and abrasion resistance, often used in soft body armor and cut-resistant gloves, enhancing protection against various threats.

Material Composition: Kevlar vs UHMWPE

Kevlar, made from para-aramid synthetic fiber, offers exceptional tensile strength and thermal stability, making it ideal for ballistic and cut-resistant applications. UHMWPE (Ultra-High Molecular Weight Polyethylene) features ultra-long molecular chains that provide superior impact resistance and lightweight durability in protective gear. The distinct molecular structures of Kevlar and UHMWPE define their specialized uses, with Kevlar excelling in heat resistance and UHMWPE delivering enhanced energy absorption.

Strength and Durability Comparison

Kevlar exhibits superior tensile strength with a breaking strength of approximately 3,620 MPa, making it highly resistant to impact and abrasion compared to UHMWPE, which has a tensile strength around 2,800 MPa. Kevlar's aromatic polyamide structure provides exceptional thermal stability and durability under high-stress conditions, whereas UHMWPE fibers, while lighter, can degrade under prolonged UV exposure and higher temperatures. The balance of strength and durability makes Kevlar the preferred material for ballistic applications requiring long-term performance in rugged environments.

Weight and Flexibility Differences

Kevlar offers high tensile strength with moderate weight, making it a reliable choice for protective gear that requires durability without excessive bulk. UHMWPE (Ultra-High-Molecular-Weight Polyethylene) provides superior lightweight properties and excellent flexibility, enhancing comfort and mobility for extended wear. The weight advantage of UHMWPE enables slimmer protective designs compared to the slightly heavier and stiffer Kevlar fibers.

Impact and Abrasion Resistance

Kevlar offers superior impact resistance due to its high tensile strength and energy absorption capabilities, making it ideal for ballistic protection and cut resistance. UHMWPE excels in abrasion resistance with its ultra-high molecular weight, providing exceptional durability against wear and tear in harsh environments. Combining Kevlar and UHMWPE materials can enhance overall protective performance by leveraging Kevlar's toughness and UHMWPE's abrasion resilience.

Ballistic Performance: Which Material Wins?

Kevlar offers exceptional ballistic performance due to its high tensile strength and ability to absorb energy upon impact, making it a preferred choice for bullet-resistant vests. UHMWPE (Ultra-High-Molecular-Weight Polyethylene) provides comparable protection with a lighter weight and higher resistance to moisture and chemicals, enhancing wearer mobility without compromising safety. In ballistic testing, UHMWPE often outperforms Kevlar in multi-hit scenarios and blunt force trauma reduction, while Kevlar remains superior in heat resistance and durability under harsh conditions.

Thermal and Chemical Resistance

Kevlar offers superior thermal resistance withstanding temperatures up to 450degC, making it ideal for environments requiring high heat protection, while UHMWPE degrades at lower temperatures near 80degC. Chemically, Kevlar resists a wide range of solvents and acids, retaining its structural integrity better than UHMWPE, which is susceptible to oxidation and UV degradation. This makes Kevlar more suitable for applications demanding durability under extreme thermal and chemical stress.

Cost and Accessibility of Kevlar vs UHMWPE

Kevlar offers a more cost-effective solution compared to UHMWPE, making it widely accessible for various protective applications such as body armor and helmets. The production cost of Kevlar fibers is generally lower, leading to reduced overall expenses for manufacturers and consumers alike. UHMWPE, while offering superior strength-to-weight ratio, tends to be pricier and less readily available, limiting its use primarily to specialized or high-end protective gear.

Typical Applications and Use Cases

Kevlar protection is widely used in ballistic vests, helmets, and automotive components due to its high tensile strength and excellent impact resistance, making it ideal for military, law enforcement, and aerospace applications. UHMWPE protection excels in lightweight body armor, cut-resistant gloves, and ballistic plates, offering superior energy absorption and corrosion resistance favored in sports, personal protective equipment, and maritime industries. Both materials provide robust defense, but Kevlar is preferred for heat resistance and multi-hit scenarios, while UHMWPE is chosen for its lighter weight and enhanced flexibility in dynamic environments.

Choosing the Right Protection: Kevlar or UHMWPE?

Kevlar offers superior abrasion resistance and thermal stability, making it ideal for environments with high heat and impact risks, while UHMWPE provides exceptional tensile strength and lighter weight, optimizing mobility and comfort. Selecting the right protection depends on application demands; Kevlar excels in ballistic and flame-resistant gear, whereas UHMWPE is preferred for lightweight ballistic vests and cut-resistant gloves. Evaluating operational conditions and required durability ensures optimal use of Kevlar's toughness or UHMWPE's strength-to-weight advantages.

Kevlar Protection vs UHMWPE Protection Infographic

materialdif.com

materialdif.com