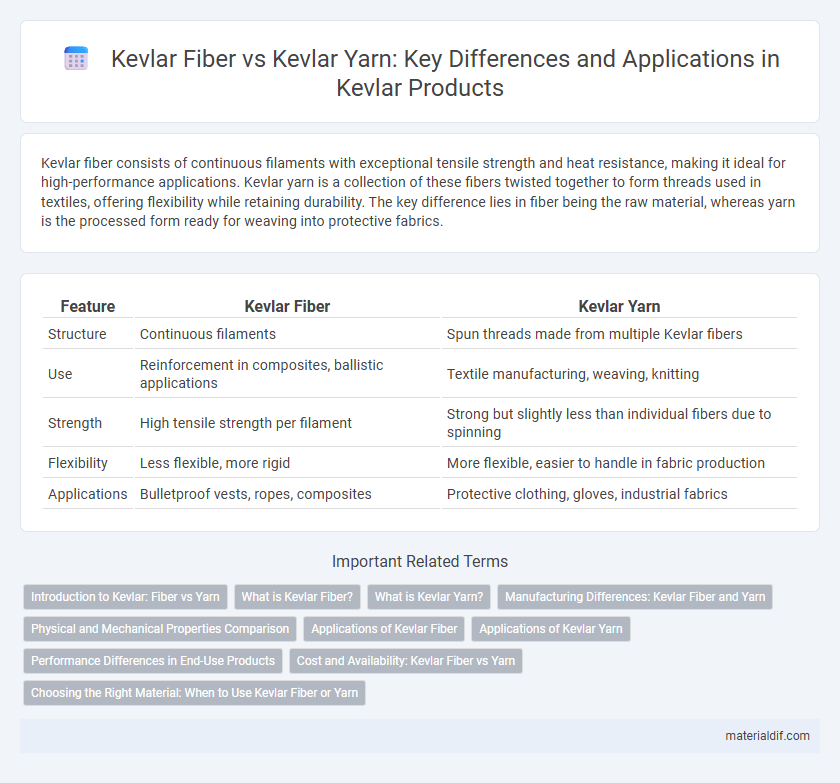

Kevlar fiber consists of continuous filaments with exceptional tensile strength and heat resistance, making it ideal for high-performance applications. Kevlar yarn is a collection of these fibers twisted together to form threads used in textiles, offering flexibility while retaining durability. The key difference lies in fiber being the raw material, whereas yarn is the processed form ready for weaving into protective fabrics.

Table of Comparison

| Feature | Kevlar Fiber | Kevlar Yarn |

|---|---|---|

| Structure | Continuous filaments | Spun threads made from multiple Kevlar fibers |

| Use | Reinforcement in composites, ballistic applications | Textile manufacturing, weaving, knitting |

| Strength | High tensile strength per filament | Strong but slightly less than individual fibers due to spinning |

| Flexibility | Less flexible, more rigid | More flexible, easier to handle in fabric production |

| Applications | Bulletproof vests, ropes, composites | Protective clothing, gloves, industrial fabrics |

Introduction to Kevlar: Fiber vs Yarn

Kevlar fiber is a continuous filament made from poly-paraphenylene terephthalamide, known for its exceptional tensile strength and thermal stability, serving as the fundamental building block for advanced materials. Kevlar yarn consists of multiple Kevlar fibers twisted or spun together, enhancing flexibility and ease of integration into textiles and composite fabrics. Both forms retain Kevlar's inherent high strength-to-weight ratio and chemical resistance, making them essential in ballistic protection, aerospace, and industrial applications.

What is Kevlar Fiber?

Kevlar fiber is a high-strength synthetic fiber made from poly-paraphenylene terephthalamide, known for its exceptional tensile strength-to-weight ratio and heat resistance. It serves as the primary raw material used to produce Kevlar yarn, which involves twisting or spinning these fibers to create threads suitable for weaving or knitting into fabrics. Kevlar fibers retain their structural integrity under extreme conditions, making them ideal for applications in body armor, aerospace, and industrial reinforcements.

What is Kevlar Yarn?

Kevlar yarn is a continuous strand composed of multiple Kevlar fibers twisted or spun together, enhancing its tensile strength and flexibility for textile manufacturing. Unlike individual Kevlar fibers, which are short and discrete, Kevlar yarns offer improved durability and uniformity, making them ideal for weaving into ballistic fabrics and high-performance composites. Their structural integrity and resistance to heat, impact, and abrasion enable applications in protective clothing, ropes, and industrial materials.

Manufacturing Differences: Kevlar Fiber and Yarn

Kevlar fiber is produced through a specialized liquid crystal polymerization process that creates continuous filaments with high tensile strength and thermal stability. Kevlar yarn, on the other hand, is manufactured by spinning multiple Kevlar fibers together, enhancing flexibility and usability in textile applications. These differences in manufacturing impact the material's performance, with fibers optimized for strength and yarns tailored for fabric integration.

Physical and Mechanical Properties Comparison

Kevlar fiber exhibits higher tensile strength and superior modulus compared to Kevlar yarn, making it more resistant to stretching and breakage under load. Kevlar yarn, composed of multiple fibers twisted together, offers enhanced flexibility and improved abrasion resistance, which is beneficial in textiles requiring durability and comfort. Both maintain excellent thermal stability and impact resistance, but the fiber's uniform structure provides more consistent mechanical properties for high-performance applications.

Applications of Kevlar Fiber

Kevlar fiber is predominantly used in high-performance applications such as ballistic and body armor, aerospace components, and industrial protective gear due to its exceptional tensile strength and lightweight properties. Kevlar yarn, derived from these fibers, is primarily utilized in textile manufacturing for creating durable fabrics used in gloves, ropes, and composite reinforcements. The direct applications of Kevlar fiber emphasize its role in structural reinforcement and impact resistance, making it essential in safety and defense industries.

Applications of Kevlar Yarn

Kevlar yarn, composed of continuous Kevlar fibers, is widely used in the manufacturing of high-performance textiles, including ballistic-resistant body armor, aerospace materials, and industrial ropes due to its exceptional tensile strength and durability. Unlike Kevlar fiber, which refers to individual filaments, Kevlar yarn provides flexibility and ease of weaving into fabrics for applications requiring lightweight, cut-resistant, and heat-resistant properties. Industries such as automotive, military, and protective clothing extensively rely on Kevlar yarn to enhance safety and performance without compromising comfort or mobility.

Performance Differences in End-Use Products

Kevlar fiber exhibits higher tensile strength and improved resistance to abrasion compared to Kevlar yarn, making it ideal for ballistic protection and industrial applications requiring maximum durability. Kevlar yarn, composed of spun fibers, offers better flexibility and ease of weaving, which enhances comfort and fit in textile products like gloves and sportswear. The performance differences significantly influence the choice between Kevlar fiber and yarn in applications where impact resistance, flexibility, and wearability are critical factors.

Cost and Availability: Kevlar Fiber vs Yarn

Kevlar fiber typically costs less per unit weight than Kevlar yarn due to its less processed form and greater raw material availability. Kevlar yarn undergoes additional spinning and twisting processes, increasing production expenses and limiting immediate supply compared to the more readily available fiber. Manufacturers often choose Kevlar fiber for bulk applications to optimize budget, while Kevlar yarn suits specialized uses demanding higher strength and uniformity despite higher costs.

Choosing the Right Material: When to Use Kevlar Fiber or Yarn

Kevlar fiber offers superior strength and heat resistance, making it ideal for high-performance composites and ballistic applications where maximum durability is critical. Kevlar yarn provides greater flexibility and is better suited for woven fabrics, ropes, and protective clothing requiring abrasion resistance and comfort. Selecting between Kevlar fiber and yarn depends on the end-use demands for tensile strength, flexibility, and specific application requirements in safety and industrial products.

Kevlar fiber vs Kevlar yarn Infographic

materialdif.com

materialdif.com