Kevlar yarn offers exceptional strength and durability compared to nylon yarn, making it ideal for pet products that require high resistance to wear and tear. Its superior cut and abrasion resistance provide enhanced protection, especially for pet harnesses and leashes exposed to rough use. Nylon yarn, while flexible and lightweight, generally lacks the toughness and heat resistance that Kevlar yarn delivers in demanding pet applications.

Table of Comparison

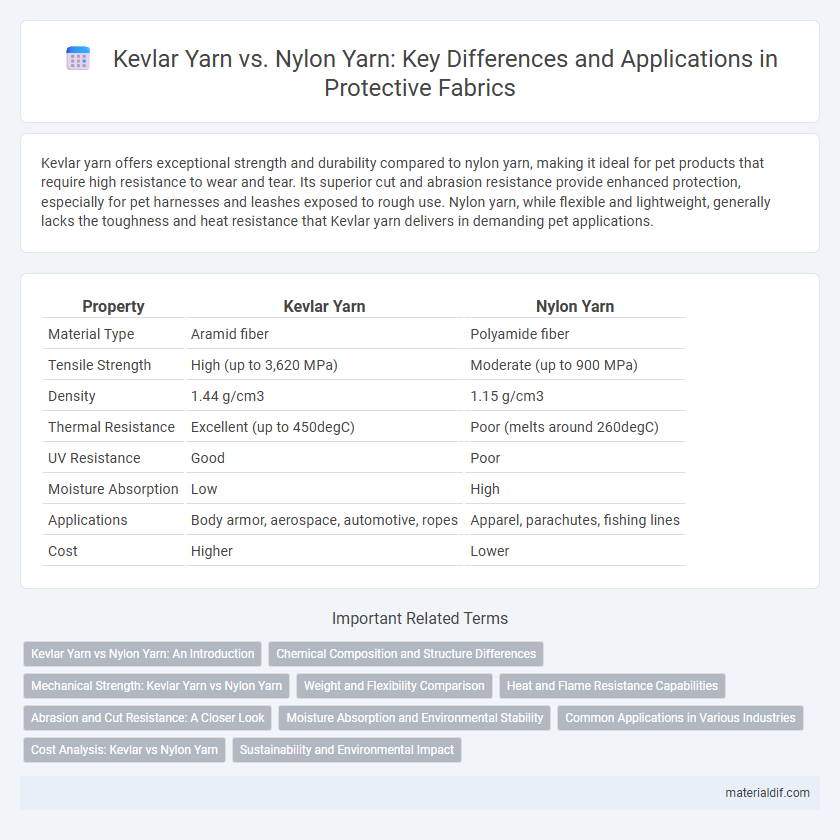

| Property | Kevlar Yarn | Nylon Yarn |

|---|---|---|

| Material Type | Aramid fiber | Polyamide fiber |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 900 MPa) |

| Density | 1.44 g/cm3 | 1.15 g/cm3 |

| Thermal Resistance | Excellent (up to 450degC) | Poor (melts around 260degC) |

| UV Resistance | Good | Poor |

| Moisture Absorption | Low | High |

| Applications | Body armor, aerospace, automotive, ropes | Apparel, parachutes, fishing lines |

| Cost | Higher | Lower |

Kevlar Yarn vs Nylon Yarn: An Introduction

Kevlar yarn exhibits superior tensile strength and heat resistance compared to nylon yarn, making it ideal for applications requiring durability and thermal stability. Its molecular structure provides exceptional resistance to abrasion, cutting, and impact, while nylon yarn is more elastic and prone to wear under harsh conditions. Kevlar yarn's unique aramid fibers contribute to its widespread use in protective gear, aerospace, and automotive industries.

Chemical Composition and Structure Differences

Kevlar yarn is composed of poly-paraphenylene terephthalamide, featuring rigid, rod-like polymer chains with strong hydrogen bonding, resulting in high tensile strength and thermal stability. Nylon yarn consists of polyamides with more flexible, coiled chains and fewer intermolecular hydrogen bonds, making it more elastic but less heat resistant. The distinct molecular alignment and chemical structure give Kevlar superior durability and resistance to abrasion compared to nylon.

Mechanical Strength: Kevlar Yarn vs Nylon Yarn

Kevlar yarn exhibits significantly higher tensile strength compared to nylon yarn, making it ideal for applications requiring exceptional mechanical durability. The molecular structure of Kevlar, characterized by rigid, rod-like polymer chains, provides superior resistance to stretching and breaking under high stress, unlike the more flexible, less crystalline nylon yarn. Kevlar's enhanced mechanical strength results in greater abrasion resistance and longevity, advantageous for protective gear and industrial uses.

Weight and Flexibility Comparison

Kevlar yarn offers superior strength-to-weight ratio compared to nylon yarn, making it significantly lighter while maintaining durability. Kevlar's molecular structure provides enhanced flexibility, allowing it to bend without breaking, unlike nylon, which tends to be stiffer under stress. This combination of lower weight and greater flexibility makes Kevlar yarn ideal for high-performance applications requiring lightweight and resilient materials.

Heat and Flame Resistance Capabilities

Kevlar yarn exhibits superior heat and flame resistance compared to nylon yarn, maintaining structural integrity at temperatures up to 450degC, whereas nylon typically melts around 260degC. Kevlar's molecular structure provides inherent flame retardancy, preventing ignition and self-extinguishing upon removal of the heat source. These properties make Kevlar yarn ideal for applications requiring enhanced thermal protection and durability in high-temperature environments.

Abrasion and Cut Resistance: A Closer Look

Kevlar yarn offers superior abrasion and cut resistance compared to nylon yarn, making it ideal for protective clothing and industrial applications. Its aramid fiber structure provides exceptional durability against wear and sharp objects, significantly outperforming the more elastic but less resilient nylon fibers. This enhanced resistance extends the lifespan of products exposed to harsh conditions, ensuring safety and reliability in demanding environments.

Moisture Absorption and Environmental Stability

Kevlar yarn exhibits significantly lower moisture absorption compared to nylon yarn, maintaining strength and dimensional stability in humid or wet conditions. Kevlar's inherent resistance to chemicals, UV radiation, and extreme temperatures enhances its environmental stability, making it ideal for demanding applications. Nylon yarn tends to absorb more moisture, which can lead to swelling, reduced mechanical properties, and faster degradation under environmental stressors.

Common Applications in Various Industries

Kevlar yarn is widely used in aerospace, military, and automotive industries due to its exceptional strength-to-weight ratio and high resistance to heat and abrasion, making it ideal for bulletproof vests, helmets, and tire reinforcements. Nylon yarn commonly finds applications in textiles, ropes, and fishing lines, valued for its elasticity, durability, and resistance to wear and chemicals. The superior tensile strength and thermal stability of Kevlar make it the preferred choice for protective gear and high-performance composites, whereas nylon's flexibility and cost-effectiveness suit everyday consumer products.

Cost Analysis: Kevlar vs Nylon Yarn

Kevlar yarn typically costs significantly more than nylon yarn due to its advanced manufacturing process and superior tensile strength, making it ideal for high-performance applications requiring durability and heat resistance. Nylon yarn is more cost-effective, widely available, and offers good elasticity and abrasion resistance, making it suitable for general-purpose textiles. The higher price of Kevlar yarn is justified in industries like automotive and defense where enhanced safety and longevity outweigh initial expenses.

Sustainability and Environmental Impact

Kevlar yarn exhibits superior sustainability compared to nylon yarn due to its high strength-to-weight ratio, enabling longer product lifespan and reduced material consumption. Kevlar fibers are more resistant to degradation, minimizing environmental waste over time, whereas nylon production relies heavily on petroleum-based resources and emits higher greenhouse gases. The biodegradability challenges of both fibers persist, but Kevlar's durability and lower ecological footprint in manufacturing contribute to a more environmentally responsible choice.

Kevlar yarn vs Nylon yarn Infographic

materialdif.com

materialdif.com