Kevlar paper offers a lightweight, flexible option for applications requiring fine detailing and precision, whereas Kevlar cloth provides superior durability and tensile strength suitable for heavy-duty protection and reinforcement. The woven structure of Kevlar cloth allows for better impact resistance and abrasion protection compared to the pressed fiber arrangement in Kevlar paper. Choosing between Kevlar paper and Kevlar cloth depends on the balance needed between flexibility and mechanical strength in pet-related gear or accessories.

Table of Comparison

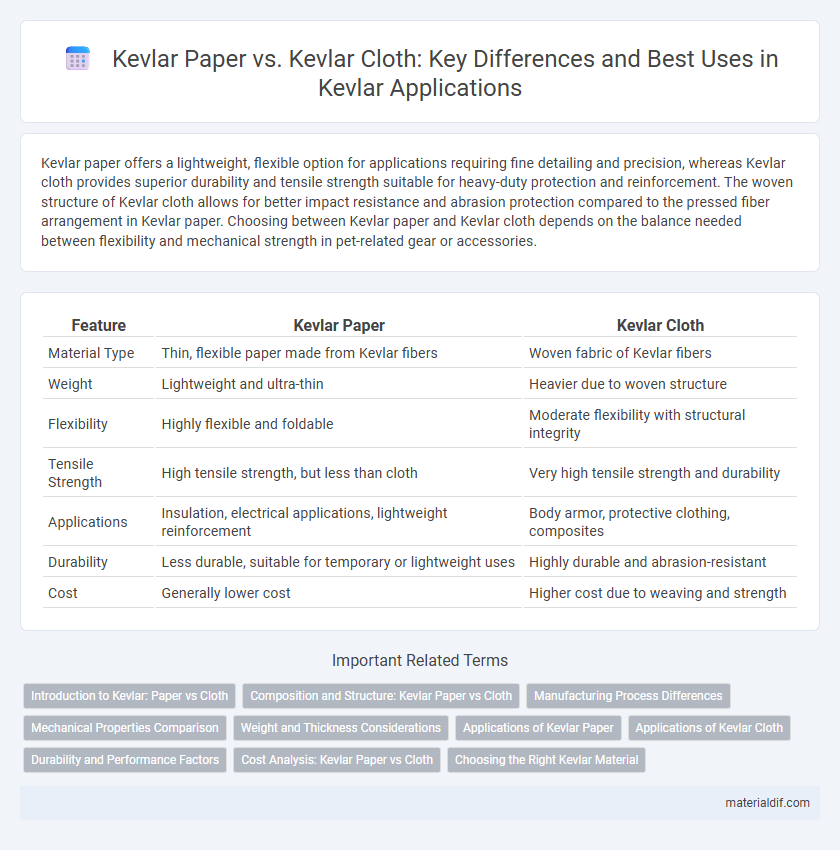

| Feature | Kevlar Paper | Kevlar Cloth |

|---|---|---|

| Material Type | Thin, flexible paper made from Kevlar fibers | Woven fabric of Kevlar fibers |

| Weight | Lightweight and ultra-thin | Heavier due to woven structure |

| Flexibility | Highly flexible and foldable | Moderate flexibility with structural integrity |

| Tensile Strength | High tensile strength, but less than cloth | Very high tensile strength and durability |

| Applications | Insulation, electrical applications, lightweight reinforcement | Body armor, protective clothing, composites |

| Durability | Less durable, suitable for temporary or lightweight uses | Highly durable and abrasion-resistant |

| Cost | Generally lower cost | Higher cost due to weaving and strength |

Introduction to Kevlar: Paper vs Cloth

Kevlar paper and Kevlar cloth both leverage the high tensile strength and heat resistance of Kevlar fibers but differ in structure and application. Kevlar paper consists of nonwoven fibers compressed into thin, flexible sheets ideal for insulation and fireproof barriers, while Kevlar cloth is woven for enhanced durability and impact resistance, commonly used in body armor and composites. These distinct formats optimize Kevlar's performance across industries by tailoring fiber orientation and density to specific protective needs.

Composition and Structure: Kevlar Paper vs Cloth

Kevlar paper consists of short, randomly oriented aramid fibers bonded into a thin, non-woven sheet that provides uniform strength and flexibility. Kevlar cloth is made from long, woven aramid fibers arranged in a grid-like pattern, offering superior tensile strength and abrasion resistance. The structural difference between the randomly aligned fibers in Kevlar paper and the woven fibers in Kevlar cloth affects their mechanical properties and suitability for specific applications like ballistic protection or composite reinforcement.

Manufacturing Process Differences

Kevlar paper is produced through a wet-laid process similar to traditional paper manufacturing, which involves suspending Kevlar pulp fibers in water and then forming them into thin sheets, resulting in a smooth, uniform texture ideal for electrical insulation and protective overlays. Kevlar cloth, on the other hand, is manufactured by weaving spun Kevlar fibers into fabric using traditional textile weaving techniques, providing enhanced tensile strength, durability, and flexibility for applications like body armor and composite materials. The key manufacturing difference lies in the transformation of Kevlar fibers into either a non-woven sheet via pulp dispersion or an interlaced woven fabric, impacting the final physical properties and application suitability.

Mechanical Properties Comparison

Kevlar paper exhibits higher tensile strength but lower tear resistance compared to Kevlar cloth, making it ideal for applications requiring rigid and lightweight reinforcement. Kevlar cloth offers superior flexibility and impact resistance due to its woven fiber structure, enhancing durability in protective gear and composite materials. Mechanical properties such as elongation at break and abrasion resistance favor Kevlar cloth, supporting its use in dynamic and high-stress environments.

Weight and Thickness Considerations

Kevlar paper offers a lightweight and ultra-thin option typically measured in microns, making it ideal for applications demanding minimal bulk and enhanced flexibility. Kevlar cloth, however, is significantly thicker and heavier due to its woven fiber structure, providing superior mechanical strength and impact resistance. Weight and thickness variations between Kevlar paper and cloth directly influence their suitability for use in composites, ballistic protection, and structural reinforcements.

Applications of Kevlar Paper

Kevlar paper is widely used in electrical insulation, gaskets, and thermal protection due to its excellent heat resistance and electrical insulation properties, distinguishing it from Kevlar cloth which is primarily used for ballistic protection and impact resistance in body armor. The flexibility and thin structure of Kevlar paper make it ideal for layering in composite materials and as reinforcement in friction materials like brake pads. Its superior chemical stability ensures durability in harsh industrial environments, making it a preferred choice for applications requiring lightweight yet strong insulating materials.

Applications of Kevlar Cloth

Kevlar cloth is extensively used in protective gear such as body armor, helmets, and gloves due to its superior tensile strength and flexibility compared to Kevlar paper. Its woven structure provides enhanced durability and impact resistance, making it ideal for military, law enforcement, and industrial safety applications. Kevlar cloth also finds applications in aerospace and automotive industries for lightweight, high-strength components.

Durability and Performance Factors

Kevlar paper offers high tensile strength and excellent thermal resistance but has limited flexibility compared to Kevlar cloth, which provides superior durability through enhanced impact absorption and flexibility. Kevlar cloth's woven structure enables better tear and abrasion resistance, making it ideal for applications requiring sustained mechanical performance and long-term wear. For performance-critical uses such as ballistic protection and industrial safety gear, Kevlar cloth delivers greater resilience and durability under dynamic stress conditions.

Cost Analysis: Kevlar Paper vs Cloth

Kevlar paper generally incurs lower material costs compared to Kevlar cloth due to its simplified production process and reduced fiber orientation requirements. While Kevlar cloth offers superior strength and flexibility for high-performance applications, its manufacturing involves weaving complex fiber patterns, increasing labor and machinery expenses. Cost analysis reveals that Kevlar paper is more economical for disposable or less demanding uses, whereas Kevlar cloth justifies its higher price through enhanced durability and protective qualities in critical safety gear.

Choosing the Right Kevlar Material

Kevlar paper and Kevlar cloth offer distinct advantages based on application requirements; Kevlar cloth provides superior tensile strength and flexibility ideal for protective clothing and reinforcement, while Kevlar paper excels in insulation and filtration due to its lightweight, porous structure. Selecting the right Kevlar material depends on factors like durability, weight, and environmental resistance, with cloth preferred for mechanical stress and paper favored for thermal and chemical applications. Evaluating product specifications such as denier, weave type, and porosity ensures optimal performance in engineering, aerospace, or safety equipment.

Kevlar paper vs Kevlar cloth Infographic

materialdif.com

materialdif.com