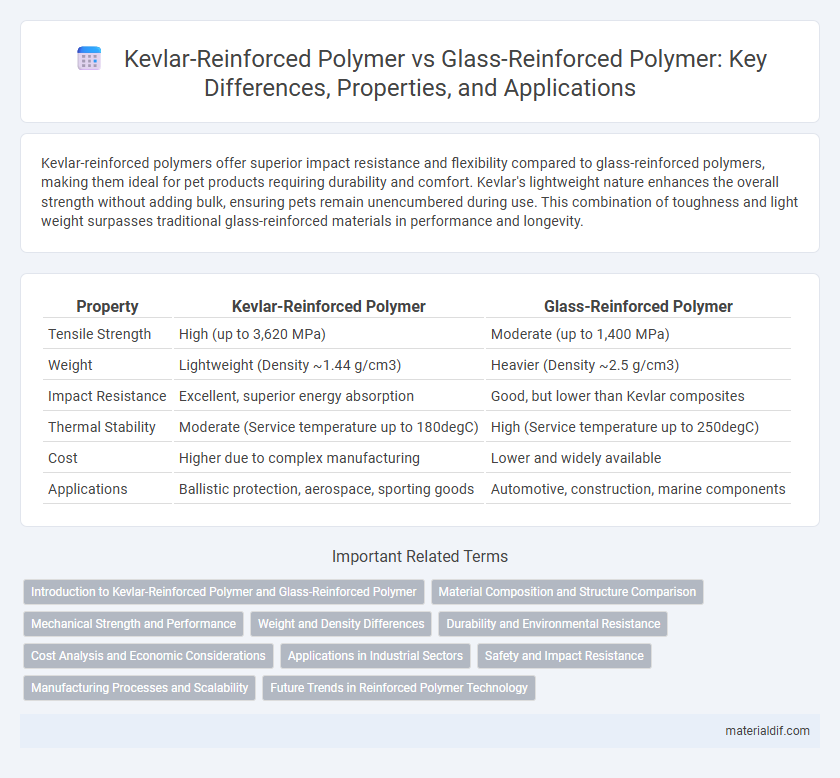

Kevlar-reinforced polymers offer superior impact resistance and flexibility compared to glass-reinforced polymers, making them ideal for pet products requiring durability and comfort. Kevlar's lightweight nature enhances the overall strength without adding bulk, ensuring pets remain unencumbered during use. This combination of toughness and light weight surpasses traditional glass-reinforced materials in performance and longevity.

Table of Comparison

| Property | Kevlar-Reinforced Polymer | Glass-Reinforced Polymer |

|---|---|---|

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 1,400 MPa) |

| Weight | Lightweight (Density ~1.44 g/cm3) | Heavier (Density ~2.5 g/cm3) |

| Impact Resistance | Excellent, superior energy absorption | Good, but lower than Kevlar composites |

| Thermal Stability | Moderate (Service temperature up to 180degC) | High (Service temperature up to 250degC) |

| Cost | Higher due to complex manufacturing | Lower and widely available |

| Applications | Ballistic protection, aerospace, sporting goods | Automotive, construction, marine components |

Introduction to Kevlar-Reinforced Polymer and Glass-Reinforced Polymer

Kevlar-reinforced polymer combines high tensile strength and exceptional impact resistance, making it ideal for applications requiring lightweight yet durable materials. Glass-reinforced polymer utilizes glass fibers to enhance structural rigidity and corrosion resistance, often preferred in environments subject to chemical exposure. Both materials serve critical roles in aerospace, automotive, and construction industries, with Kevlar offering superior toughness and glass fiber contributing to cost-effective reinforcement.

Material Composition and Structure Comparison

Kevlar-reinforced polymers consist of aramid fibers known for their high tensile strength and lightweight properties, providing exceptional impact resistance and durability. Glass-reinforced polymers use glass fibers that offer good stiffness and moderate strength but are heavier and more brittle compared to Kevlar composites. The molecular structure of Kevlar features tightly bonded aromatic polyamide chains, enhancing toughness, while glass fibers are inorganic and brittle, influencing the composite's overall mechanical performance.

Mechanical Strength and Performance

Kevlar-reinforced polymers exhibit superior tensile strength and impact resistance compared to glass-reinforced polymers, making them ideal for high-performance applications requiring lightweight durability. The fiber's high modulus and energy absorption capacity enhance mechanical strength and fatigue resistance, surpassing glass fibers in dynamic load environments. Kevlar composites also provide better performance in terms of damage tolerance and ballistic protection, crucial for aerospace and defense industries.

Weight and Density Differences

Kevlar-reinforced polymer composites exhibit significantly lower density, typically around 1.44 g/cm3, compared to glass-reinforced polymers, which average about 2.5 g/cm3, resulting in lighter structural components. This weight difference translates to enhanced performance in aerospace and automotive applications where weight reduction is critical for fuel efficiency and handling. Kevlar's superior strength-to-weight ratio enables designers to achieve durable yet lightweight parts, outperforming glass fibers in scenarios demanding reduced mass.

Durability and Environmental Resistance

Kevlar-reinforced polymers exhibit superior durability due to Kevlar's high tensile strength and excellent impact resistance, making them ideal for applications requiring long-term structural integrity. These composites also demonstrate enhanced environmental resistance, particularly against moisture, UV radiation, and chemical exposure, outperforming glass-reinforced polymers that tend to degrade or suffer from stress corrosion in harsh conditions. Kevlar's resistance to fatigue and abrasion further contributes to the longevity and reliability of Kevlar-reinforced polymer composites in demanding environments.

Cost Analysis and Economic Considerations

Kevlar-reinforced polymers typically exhibit higher material costs compared to glass-reinforced polymers due to the advanced manufacturing processes and superior tensile strength of Kevlar fibers. Despite the elevated initial investment, Kevlar's enhanced durability and impact resistance often result in lower replacement and maintenance expenses over the product lifecycle. Economic considerations must weigh the upfront price difference against long-term savings in applications requiring high-performance materials with critical weight and strength requirements.

Applications in Industrial Sectors

Kevlar-reinforced polymers offer superior tensile strength and impact resistance, making them ideal for aerospace, automotive, and military applications where lightweight and high durability are critical. Glass-reinforced polymers excel in cost-effective construction, marine, and infrastructure sectors due to their corrosion resistance and ease of fabrication. Both materials enhance performance in industrial sectors, but Kevlar composites are preferred for high-stress environments, while glass-reinforced options suit large-scale structural uses.

Safety and Impact Resistance

Kevlar-reinforced polymers exhibit superior impact resistance compared to glass-reinforced polymers, absorbing and dissipating energy more efficiently due to Kevlar's high tensile strength and toughness. These materials enhance safety in protective gear and structural applications by reducing the risk of fracture and penetration under sudden impacts. Kevlar's lightweight nature also contributes to better maneuverability without compromising protective performance.

Manufacturing Processes and Scalability

Kevlar-reinforced polymers demand precise handling during manufacturing due to Kevlar's sensitivity to cutting and water absorption, requiring specialized resin impregnation and molding techniques that increase production complexity compared to glass-reinforced polymers. Glass-reinforced polymers benefit from established, cost-effective processes like compression molding and filament winding, enabling higher scalability and faster production rates in industrial applications. The scalability of Kevlar composites is often limited by slower curing cycles and more stringent quality control measures, whereas glass composites allow more straightforward mass production with consistent mechanical properties.

Future Trends in Reinforced Polymer Technology

Kevlar-reinforced polymers exhibit superior tensile strength and impact resistance compared to glass-reinforced polymers, driving their adoption in aerospace and automotive sectors where weight reduction is critical. Emerging trends emphasize hybrid composites combining Kevlar and glass fibers to optimize cost efficiency and mechanical performance in next-generation materials. Advances in nanotechnology and bio-based resins are expected to further enhance the durability and sustainability of Kevlar-reinforced polymer systems.

Kevlar-reinforced polymer vs Glass-reinforced polymer Infographic

materialdif.com

materialdif.com