Kevlar sheets provide a strong, flexible barrier ideal for protective pet gear, offering broad coverage and enhanced durability. Kevlar cords deliver high tensile strength and versatility for custom applications like harnesses or leash reinforcements. Choosing between them depends on the specific pet protection needs, balancing surface protection and structural support.

Table of Comparison

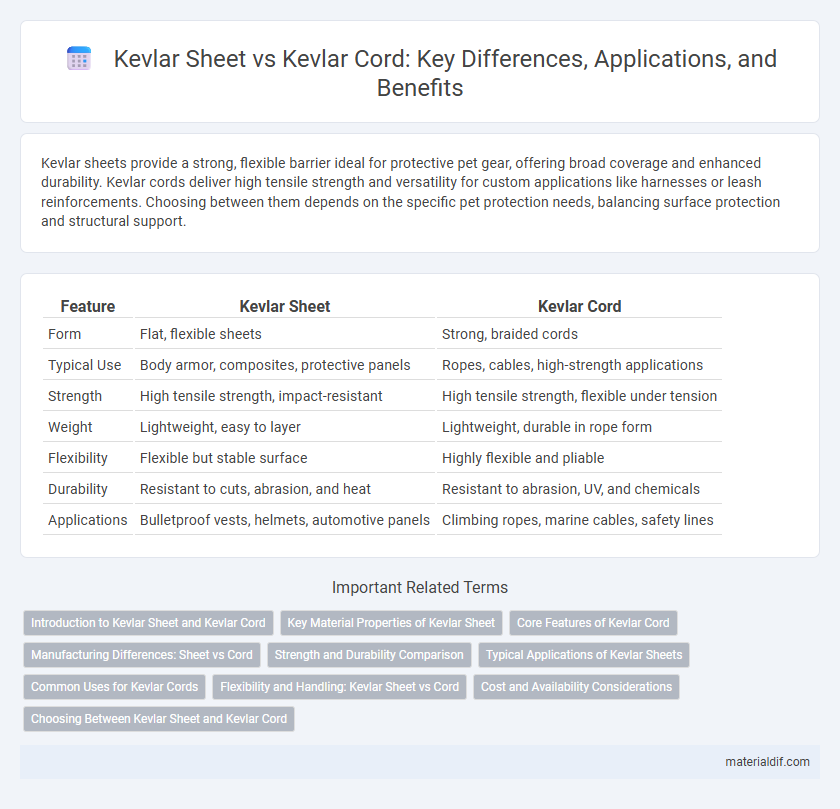

| Feature | Kevlar Sheet | Kevlar Cord |

|---|---|---|

| Form | Flat, flexible sheets | Strong, braided cords |

| Typical Use | Body armor, composites, protective panels | Ropes, cables, high-strength applications |

| Strength | High tensile strength, impact-resistant | High tensile strength, flexible under tension |

| Weight | Lightweight, easy to layer | Lightweight, durable in rope form |

| Flexibility | Flexible but stable surface | Highly flexible and pliable |

| Durability | Resistant to cuts, abrasion, and heat | Resistant to abrasion, UV, and chemicals |

| Applications | Bulletproof vests, helmets, automotive panels | Climbing ropes, marine cables, safety lines |

Introduction to Kevlar Sheet and Kevlar Cord

Kevlar sheets are flat, flexible materials composed of woven Kevlar fibers, primarily used for applications requiring strong, lightweight, and cut-resistant surfaces such as body armor panels and protective gear. Kevlar cords are continuous strands made from twisted Kevlar fibers, ideal for high-tensile strength uses like ropes, cables, and reinforcement in composites. Both forms leverage Kevlar's exceptional strength-to-weight ratio and heat resistance but differ in structure and application specificity.

Key Material Properties of Kevlar Sheet

Kevlar sheet exhibits exceptional tensile strength, high thermal resistance, and excellent durability, making it ideal for protective gear and composite applications. Its flat, uniform structure provides superior impact resistance and consistent mechanical performance across surfaces. Compared to Kevlar cord, the sheet form offers enhanced flexibility in layering and shaping for customized armor and industrial uses.

Core Features of Kevlar Cord

Kevlar cord is characterized by its exceptional tensile strength, flexibility, and resistance to abrasion, making it ideal for applications requiring durable, high-performance reinforcement. Unlike Kevlar sheets, which provide flat, rigid protection, Kevlar cords offer superior adaptability in complex and curved structures, enabling enhanced impact absorption and weight reduction. Core features of Kevlar cord include high strength-to-weight ratio, excellent thermal stability, and resistance to chemical degradation, ensuring reliability in demanding industrial, marine, and ballistic environments.

Manufacturing Differences: Sheet vs Cord

Kevlar sheets are manufactured through a heat-pressing process that compacts woven Kevlar fibers into flat, rigid panels ideal for ballistic and structural applications. Kevlar cords are produced by twisting high-strength Kevlar filaments into flexible, durable ropes or threads suitable for reinforcement in composite materials and protective gear. The key manufacturing divergence lies in the transformation of raw Kevlar fibers--either woven and pressed into sheets or spun and twisted into cords--resulting in distinct mechanical properties tailored to specific industrial uses.

Strength and Durability Comparison

Kevlar Sheets offer superior tensile strength and impact resistance, making them ideal for applications requiring broad surface protection and structural reinforcement. Kevlar Cords provide exceptional flexibility and high tensile strength along a single axis, suitable for rope, cables, and tensioning systems. In terms of durability, Kevlar Sheets resist abrasion and wear effectively over large areas, while Kevlar Cords excel under dynamic loads and repeated flexing without compromising integrity.

Typical Applications of Kevlar Sheets

Kevlar sheets are predominantly used in ballistic armor, protective gear, and aerospace components due to their high tensile strength and lightweight properties. These sheets provide excellent resistance to impact, abrasion, and heat, making them ideal for body armor, helmets, and reinforcement panels in aircraft and vehicles. In contrast, Kevlar cords are typically employed in rope, cable, and composite reinforcements where flexibility and tensile strength are critical.

Common Uses for Kevlar Cords

Kevlar cords are primarily used in applications requiring high tensile strength and flexibility, such as in marine ropes, climbing gear, and protective apparel reinforcement. Their ability to absorb impact and resist abrasion makes them ideal for manufacturing cables, fishing lines, and ballistic reinforcements. Unlike Kevlar sheets, which provide flat, rigid protection, Kevlar cords offer versatility in dynamic tension environments and complex shapes.

Flexibility and Handling: Kevlar Sheet vs Cord

Kevlar sheet offers greater flexibility and ease of handling due to its flat, continuous structure, making it ideal for wrapping and layering applications that require smooth contours. Kevlar cord, composed of braided or twisted fibers, provides superior tensile strength but is less flexible and more challenging to manipulate around complex shapes. Choosing between Kevlar sheet and cord depends on the specific application's need for flexibility versus structural reinforcement.

Cost and Availability Considerations

Kevlar sheets are generally more expensive than Kevlar cords due to the manufacturing complexity and the larger surface area covered, making them less cost-effective for small-scale applications. Kevlar cords offer greater availability in various thicknesses and lengths, catering to diverse uses with more flexible pricing options. Cost efficiency and stock accessibility make Kevlar cords preferable for projects requiring customization and budget management, while Kevlar sheets are selected for high-strength, uniform layering needs.

Choosing Between Kevlar Sheet and Kevlar Cord

Kevlar sheets offer flat, flexible strength ideal for protective panels, ballistic armor, and impact-resistant applications, whereas Kevlar cords provide high tensile strength suited for ropes, cables, and composite reinforcement. Selecting between Kevlar sheet and Kevlar cord depends on the specific use case: sheets excel in surface coverage and impact distribution, while cords are preferred for tensile load-bearing and flexibility. Consider factors like load type, shape requirements, and environmental exposure to optimize performance and durability in your application.

Kevlar Sheet vs Kevlar Cord Infographic

materialdif.com

materialdif.com