Kevlar ropes offer superior strength and abrasion resistance compared to nylon ropes, making them ideal for heavy-duty pet applications such as high-stress leash uses or harnesses. Unlike nylon, Kevlar is less stretchy, providing better control and durability for active pets prone to pulling. Nylon ropes are more affordable and flexible but lack the long-term toughness and resistance to wear that Kevlar provides in demanding environments.

Table of Comparison

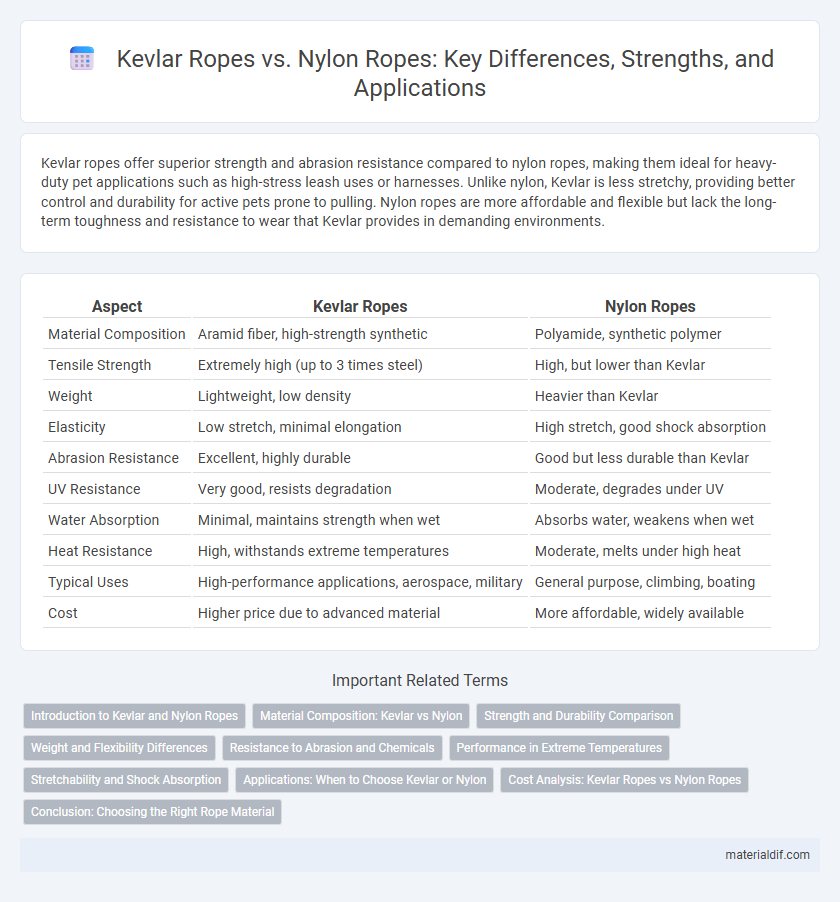

| Aspect | Kevlar Ropes | Nylon Ropes |

|---|---|---|

| Material Composition | Aramid fiber, high-strength synthetic | Polyamide, synthetic polymer |

| Tensile Strength | Extremely high (up to 3 times steel) | High, but lower than Kevlar |

| Weight | Lightweight, low density | Heavier than Kevlar |

| Elasticity | Low stretch, minimal elongation | High stretch, good shock absorption |

| Abrasion Resistance | Excellent, highly durable | Good but less durable than Kevlar |

| UV Resistance | Very good, resists degradation | Moderate, degrades under UV |

| Water Absorption | Minimal, maintains strength when wet | Absorbs water, weakens when wet |

| Heat Resistance | High, withstands extreme temperatures | Moderate, melts under high heat |

| Typical Uses | High-performance applications, aerospace, military | General purpose, climbing, boating |

| Cost | Higher price due to advanced material | More affordable, widely available |

Introduction to Kevlar and Nylon Ropes

Kevlar ropes are made from aramid fibers known for their exceptional tensile strength, heat resistance, and low stretch properties, making them ideal for high-performance applications in marine, climbing, and industrial settings. Nylon ropes consist of synthetic polyamide fibers offering excellent elasticity, shock absorption, and abrasion resistance, commonly used in general-purpose tasks such as towing and securing loads. Both rope types serve critical roles in safety and durability, with Kevlar excelling in strength and heat tolerance, while nylon provides flexibility and resilience.

Material Composition: Kevlar vs Nylon

Kevlar ropes are composed of para-aramid synthetic fibers known for high tensile strength, exceptional heat resistance, and minimal stretch, making them ideal for heavy-duty and safety-critical applications. Nylon ropes consist of polyamide fibers that offer excellent elasticity, abrasion resistance, and shock absorption but have lower heat resistance compared to Kevlar. The intrinsic molecular structure of Kevlar fibers provides superior durability and performance under extreme conditions compared to the more flexible and resilient nylon fibers.

Strength and Durability Comparison

Kevlar ropes exhibit superior tensile strength compared to nylon ropes, often withstanding over five times the force before breaking, making them ideal for high-stress applications. Kevlar's molecular structure provides exceptional resistance to abrasion, heat, and UV degradation, significantly enhancing its durability in harsh environments. Nylon ropes, while more elastic and resistant to impact shock, tend to degrade faster under prolonged exposure to sunlight and chemicals, reducing their long-term reliability.

Weight and Flexibility Differences

Kevlar ropes are significantly lighter than nylon ropes, offering superior strength-to-weight ratio ideal for applications requiring ease of handling and reduced load. Kevlar's high tensile strength ensures durability while maintaining minimal stretch, whereas nylon ropes are heavier and exhibit more elasticity, which can absorb shock but may compromise precision in certain tasks. The flexibility of nylon ropes is greater, making them easier to knot and manipulate, but Kevlar ropes provide enhanced resistance to abrasion and heat, balancing flexibility with long-term performance.

Resistance to Abrasion and Chemicals

Kevlar ropes exhibit superior resistance to abrasion due to their aramid fiber composition, which maintains structural integrity under friction better than nylon ropes. Chemically, Kevlar resists degradation from oils, solvents, and alkalis more effectively, whereas nylon can absorb moisture and deteriorate when exposed to certain chemicals. This makes Kevlar ropes ideal for harsh environments requiring prolonged durability and high-performance resistance.

Performance in Extreme Temperatures

Kevlar ropes maintain exceptional strength and durability in extreme temperatures, withstanding heat up to 450degC without significant degradation, making them ideal for high-temperature environments. Nylon ropes tend to lose tensile strength and elasticity when exposed to both high heat above 80degC and freezing temperatures below -40degC, limiting their effectiveness in harsh conditions. The superior thermal resistance of Kevlar ensures consistent performance and longer lifespan compared to nylon in demanding temperature extremes.

Stretchability and Shock Absorption

Kevlar ropes exhibit significantly lower stretchability compared to nylon ropes, making them ideal for applications requiring minimal elongation under load. Their superior shock absorption capabilities help reduce impact forces, enhancing safety in critical scenarios such as climbing and industrial use. Nylon ropes, with higher elasticity, provide greater stretch but less precise control over dynamic loads, influencing their suitability where flexibility is prioritized.

Applications: When to Choose Kevlar or Nylon

Kevlar ropes are ideal for applications requiring high tensile strength and resistance to heat, such as firefighting, military use, and aerospace, where durability and safety under extreme conditions are critical. Nylon ropes excel in scenarios demanding elasticity and shock absorption, including climbing, towing, and marine environments, benefiting from their flexibility and resistance to abrasion. Choosing Kevlar over nylon depends on the need for minimal stretch and maximum strength, while nylon is preferred for dynamic loads and impact resistance.

Cost Analysis: Kevlar Ropes vs Nylon Ropes

Kevlar ropes command a higher price point due to their superior tensile strength, heat resistance, and durability compared to nylon ropes. Nylon ropes, while more affordable, offer greater elasticity and UV resistance but may require more frequent replacement in high-stress applications, affecting long-term costs. Evaluating the total cost of ownership involves weighing initial investment against performance benefits, maintenance needs, and lifespan in specific use cases.

Conclusion: Choosing the Right Rope Material

Kevlar ropes offer exceptional strength, low stretch, and superior heat resistance compared to nylon ropes, making them ideal for high-performance applications like industrial lifting and marine use. Nylon ropes provide greater elasticity and shock absorption, which benefits dynamic loads and general-purpose tasks. Selecting between Kevlar and nylon ropes depends primarily on the specific demands of strength, durability, and flexibility required for the intended use.

Kevlar Ropes vs Nylon Ropes Infographic

materialdif.com

materialdif.com