Wet-layup Kevlar pet composites offer greater flexibility in fabrication with room-temperature curing, making them suitable for custom, low-volume production. Pre-preg Kevlar pet materials ensure superior fiber-resin ratio control and enhanced mechanical properties due to their pre-impregnated resin systems and precision curing cycles. Choosing between wet-layup and pre-preg depends on the desired balance of production efficiency, performance consistency, and cost-effectiveness in Kevlar pet composite applications.

Table of Comparison

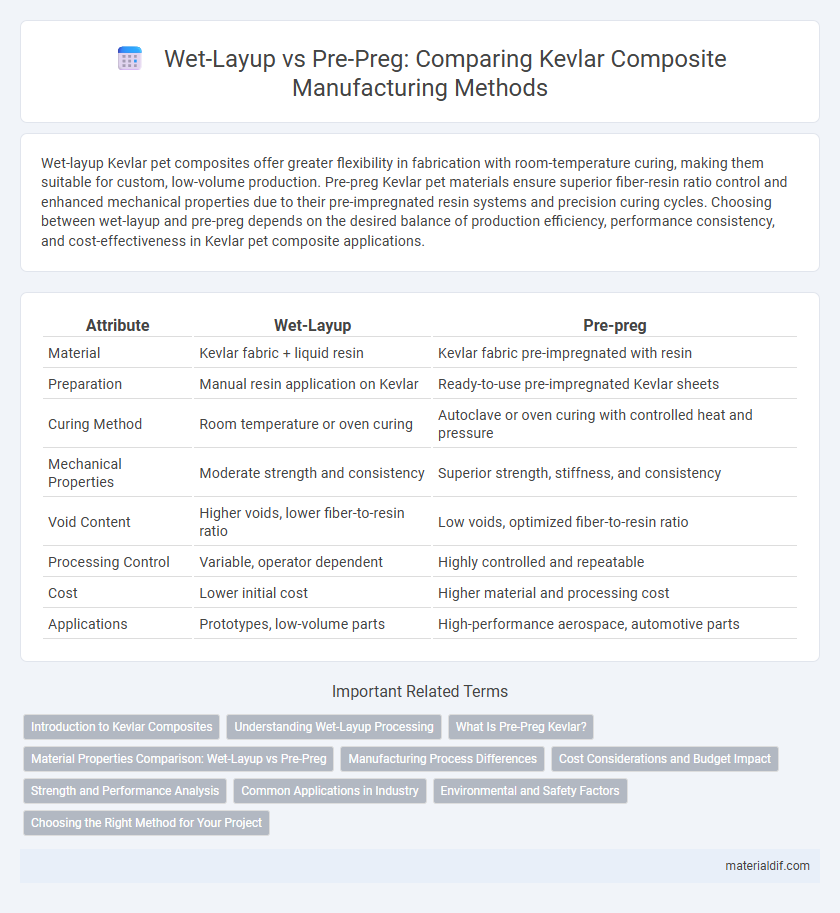

| Attribute | Wet-Layup | Pre-preg |

|---|---|---|

| Material | Kevlar fabric + liquid resin | Kevlar fabric pre-impregnated with resin |

| Preparation | Manual resin application on Kevlar | Ready-to-use pre-impregnated Kevlar sheets |

| Curing Method | Room temperature or oven curing | Autoclave or oven curing with controlled heat and pressure |

| Mechanical Properties | Moderate strength and consistency | Superior strength, stiffness, and consistency |

| Void Content | Higher voids, lower fiber-to-resin ratio | Low voids, optimized fiber-to-resin ratio |

| Processing Control | Variable, operator dependent | Highly controlled and repeatable |

| Cost | Lower initial cost | Higher material and processing cost |

| Applications | Prototypes, low-volume parts | High-performance aerospace, automotive parts |

Introduction to Kevlar Composites

Kevlar composites exhibit exceptional strength-to-weight ratios, making them ideal for advanced applications such as aerospace and ballistic protection. Wet-layup involves manually applying resin to Kevlar fabric, offering flexibility but less consistency in fiber-resin impregnation. Pre-preg Kevlar composites use pre-impregnated fibers with precise resin content, enhancing structural performance and reducing voids for high-quality, repeatable results.

Understanding Wet-Layup Processing

Wet-layup processing involves manually applying resin directly onto Kevlar fibers and layering them by hand, allowing for flexibility in molds and cost-effective production. This method offers easier customization and quicker repairs compared to pre-preg, which uses pre-impregnated Kevlar fiber sheets with controlled resin content requiring refrigerated storage. Understanding the wet-layup technique is essential for optimizing Kevlar composite structures in industries like marine, automotive, and sports equipment manufacturing.

What Is Pre-Preg Kevlar?

Pre-preg Kevlar consists of Kevlar fibers pre-impregnated with a partially cured resin system, offering precise resin-to-fiber ratios that enhance composite strength and consistency. This method ensures uniform resin distribution and superior control over fiber alignment compared to wet-layup processes. Pre-preg Kevlar is commonly used in aerospace, automotive, and protective equipment manufacturing where high-performance, lightweight materials are critical.

Material Properties Comparison: Wet-Layup vs Pre-Preg

Wet-layup Kevlar composites typically exhibit lower fiber volume fractions and reduced mechanical strength compared to pre-preg materials, which feature more uniform resin distribution and higher-quality fiber impregnation. Pre-preg Kevlar offers superior tensile strength, impact resistance, and predictable curing behavior due to its controlled resin-to-fiber ratio and pre-impregnated fibers. Moisture absorption and void content are generally higher in wet-layup Kevlar, resulting in decreased durability and performance in demanding structural applications.

Manufacturing Process Differences

Wet-layup involves manually impregnating Kevlar fibers with resin during the layup process, offering flexibility but often resulting in inconsistent resin distribution and longer curing times. Pre-preg Kevlar utilizes fibers pre-impregnated with a precise resin ratio, enabling controlled curing under heat and pressure, which enhances fiber-resin bonding and part uniformity. The manufacturing process for pre-preg typically requires refrigeration storage and autoclave curing, whereas wet-layup can be performed at room temperature with simpler equipment.

Cost Considerations and Budget Impact

Wet-layup Kevlar composites typically offer lower upfront material costs compared to pre-preg options, making them suitable for budget-sensitive projects. Pre-preg Kevlar, while more expensive due to advanced processing and storage requirements, provides superior fiber-resin ratios and consistent quality, potentially reducing labor and rework expenses over time. Selecting wet-layup versus pre-preg impacts overall project budgets by balancing initial savings against long-term performance and manufacturing efficiency.

Strength and Performance Analysis

Wet-layup Kevlar composites often exhibit lower fiber-to-resin ratios and inconsistent resin distribution, resulting in reduced tensile strength and impact resistance compared to pre-preg counterparts. Pre-preg Kevlar materials benefit from precise resin content control and uniform fiber alignment, providing superior mechanical performance and enhanced durability under stress. Strength analysis consistently shows pre-preg Kevlar laminates achieving higher interlaminar shear strength and fatigue resistance, critical for high-performance aerospace and automotive applications.

Common Applications in Industry

Wet-layup Kevlar is widely used in marine and automotive industries for custom, repair, and prototyping applications due to its cost-effectiveness and ease of handling. Pre-preg Kevlar finds extensive use in aerospace and high-performance sporting goods where precise fiber alignment and superior mechanical properties are critical. Both methods contribute significantly to the production of lightweight, durable composites essential for impact resistance and structural reinforcement.

Environmental and Safety Factors

Wet-layup of Kevlar involves handling liquid resins that emit volatile organic compounds (VOCs), posing respiratory hazards and requiring extensive ventilation systems to ensure worker safety. Pre-preg Kevlar materials are partially cured and fully impregnated with resin, minimizing VOC emissions and reducing risks of chemical exposure but necessitating strict cold storage to prevent premature curing. Both methods demand proper protective equipment, though pre-preg offers environmentally cleaner processing with lower hazardous waste generation.

Choosing the Right Method for Your Project

Wet-layup offers flexibility and cost-efficiency for small-scale or custom Kevlar composite projects, using resin applied manually to dry Kevlar fabrics. Pre-preg Kevlar provides superior strength and consistency with pre-impregnated fibers, ideal for high-performance and aerospace applications requiring precise curing and minimal voids. Selecting the right method depends on project scale, budget, mechanical performance needs, and available curing facilities.

Wet-layup vs Pre-preg Infographic

materialdif.com

materialdif.com