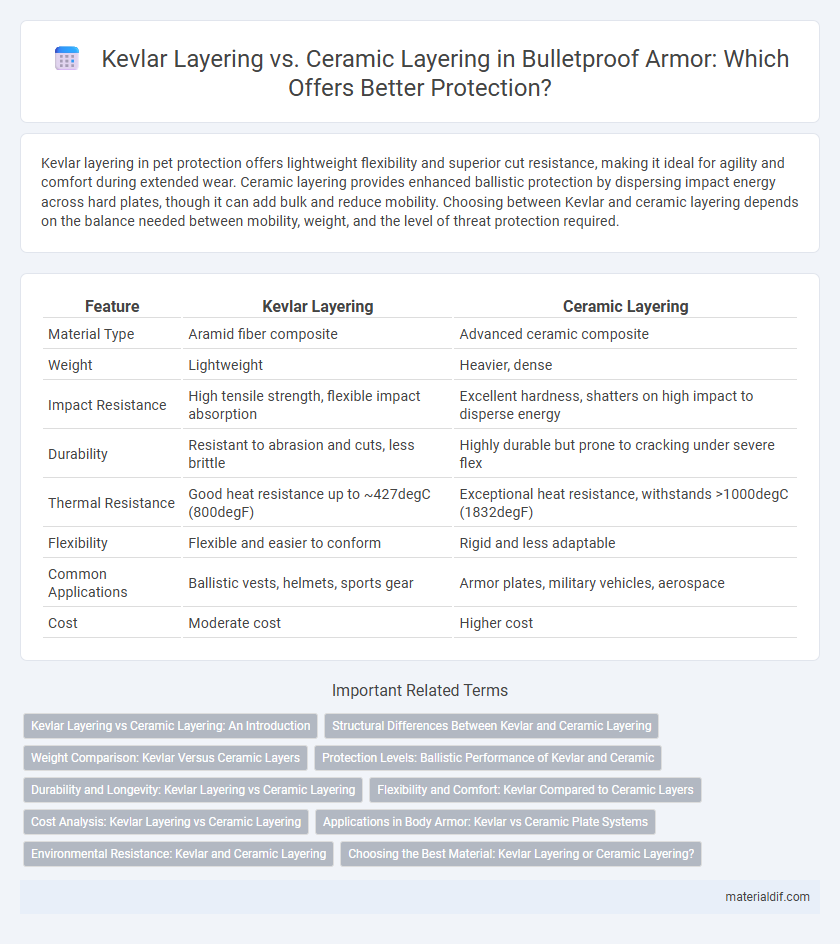

Kevlar layering in pet protection offers lightweight flexibility and superior cut resistance, making it ideal for agility and comfort during extended wear. Ceramic layering provides enhanced ballistic protection by dispersing impact energy across hard plates, though it can add bulk and reduce mobility. Choosing between Kevlar and ceramic layering depends on the balance needed between mobility, weight, and the level of threat protection required.

Table of Comparison

| Feature | Kevlar Layering | Ceramic Layering |

|---|---|---|

| Material Type | Aramid fiber composite | Advanced ceramic composite |

| Weight | Lightweight | Heavier, dense |

| Impact Resistance | High tensile strength, flexible impact absorption | Excellent hardness, shatters on high impact to disperse energy |

| Durability | Resistant to abrasion and cuts, less brittle | Highly durable but prone to cracking under severe flex |

| Thermal Resistance | Good heat resistance up to ~427degC (800degF) | Exceptional heat resistance, withstands >1000degC (1832degF) |

| Flexibility | Flexible and easier to conform | Rigid and less adaptable |

| Common Applications | Ballistic vests, helmets, sports gear | Armor plates, military vehicles, aerospace |

| Cost | Moderate cost | Higher cost |

Kevlar Layering vs Ceramic Layering: An Introduction

Kevlar layering consists of multiple woven aramid fiber sheets that provide exceptional tensile strength and lightweight ballistic protection ideal for flexible armor solutions. In contrast, ceramic layering uses hard, brittle plates that disrupt and absorb high-velocity projectiles through fracture and energy dispersion, offering superior protection against armor-piercing rounds. Kevlar layers excel in multi-hit resistance and flexibility, while ceramic layers deliver enhanced stopping power against high-caliber threats but often require backing materials like Kevlar for complete structural integrity.

Structural Differences Between Kevlar and Ceramic Layering

Kevlar layering consists of woven aramid fibers that create flexible, lightweight armor capable of absorbing and distributing kinetic energy, enhancing impact resistance through fiber deformation. Ceramic layering involves hard, brittle plates made from materials like alumina or silicon carbide designed to shatter incoming projectiles, dissipating energy while relying on backing materials for structural support. The primary structural difference lies in Kevlar's fibrous, pliable matrix versus ceramic's rigid, brittle composition, resulting in distinct mechanisms for ballistic protection and layering strategies.

Weight Comparison: Kevlar Versus Ceramic Layers

Kevlar layering offers a significant weight advantage over ceramic layering in body armor applications, with Kevlar being up to 40% lighter while maintaining high ballistic resistance. Ceramic layers provide superior hardness and impact dispersion but add substantial weight, often increasing the overall armor weight by 20-30%. This weight difference makes Kevlar preferable for mobility-focused gear and extended wear scenarios where reduced load is critical.

Protection Levels: Ballistic Performance of Kevlar and Ceramic

Kevlar layering offers high tensile strength and flexibility, providing effective ballistic protection against shrapnel and low-velocity projectiles through energy absorption and fiber deformation. Ceramic layering excels in stopping high-velocity rifle rounds by fracturing the projectile and dissipating impact energy across the plate, though it is more brittle and prone to cracking. Combining Kevlar with ceramic layers enhances overall protection by leveraging ceramic's hardness for initial impact resistance and Kevlar's flexibility for preventing penetration and reducing blunt force trauma.

Durability and Longevity: Kevlar Layering vs Ceramic Layering

Kevlar layering offers exceptional flexibility and impact resistance, providing durability through multiple fiber layers that absorb and disperse energy effectively. Ceramic layering excels in hardness and abrasion resistance, ensuring longevity by creating a rigid barrier that resists penetration and wear over time. Comparing durability, Kevlar maintains integrity under repeated stress, while ceramic layers provide superior protection against high-velocity threats but may be prone to cracking under impact.

Flexibility and Comfort: Kevlar Compared to Ceramic Layers

Kevlar layering offers superior flexibility and comfort compared to ceramic layering due to its lightweight and woven fiber structure, which allows for better movement and reduced bulk. Ceramics, while highly effective at ballistic protection, tend to be rigid and heavier, often causing discomfort during extended wear or dynamic activities. The pliability of Kevlar makes it ideal for applications requiring agility without compromising safety.

Cost Analysis: Kevlar Layering vs Ceramic Layering

Kevlar layering offers a cost-effective solution with lower material and manufacturing expenses compared to ceramic layering, which involves higher costs due to advanced ceramic fabrication techniques and raw material prices. While ceramic layers provide superior hardness and ballistic protection, Kevlar's flexibility and lighter weight reduce overall production and installation costs. Budget-sensitive applications often favor Kevlar layering for an optimal balance between performance and expense.

Applications in Body Armor: Kevlar vs Ceramic Plate Systems

Kevlar layering in body armor offers flexibility and lightweight protection, making it ideal for tactical vests and soft armor applications where mobility is crucial. Ceramic plate systems provide superior ballistic resistance against high-velocity rifle rounds by dispersing impact energy across a hard surface, commonly used in hard armor plates for frontline combat. Combining Kevlar layers with ceramic plates enhances overall defense by balancing durability, weight, and multi-threat protection in modern ballistic armor systems.

Environmental Resistance: Kevlar and Ceramic Layering

Kevlar layering exhibits excellent environmental resistance by maintaining structural integrity under extreme temperature fluctuations and high humidity, making it ideal for lightweight body armor and aerospace applications. Ceramic layering offers superior resistance to high-velocity impacts and extreme heat, excelling in ballistic protection but often requiring additional composite materials for enhanced environmental durability. Combining Kevlar with ceramic layers optimizes resistance against environmental factors while providing robust impact absorption in advanced protective gear.

Choosing the Best Material: Kevlar Layering or Ceramic Layering?

Kevlar layering offers superior flexibility and impact resistance, making it ideal for lightweight ballistic protection and high-mobility applications. Ceramic layering provides exceptional hardness and superior penetration resistance against high-velocity projectiles but adds weight and rigidity. Choosing the best material depends on balancing operational needs for mobility versus maximum protection, with Kevlar suited for sustained wear and ceramic preferred for front-line defense against armor-piercing threats.

Kevlar Layering vs Ceramic Layering Infographic

materialdif.com

materialdif.com