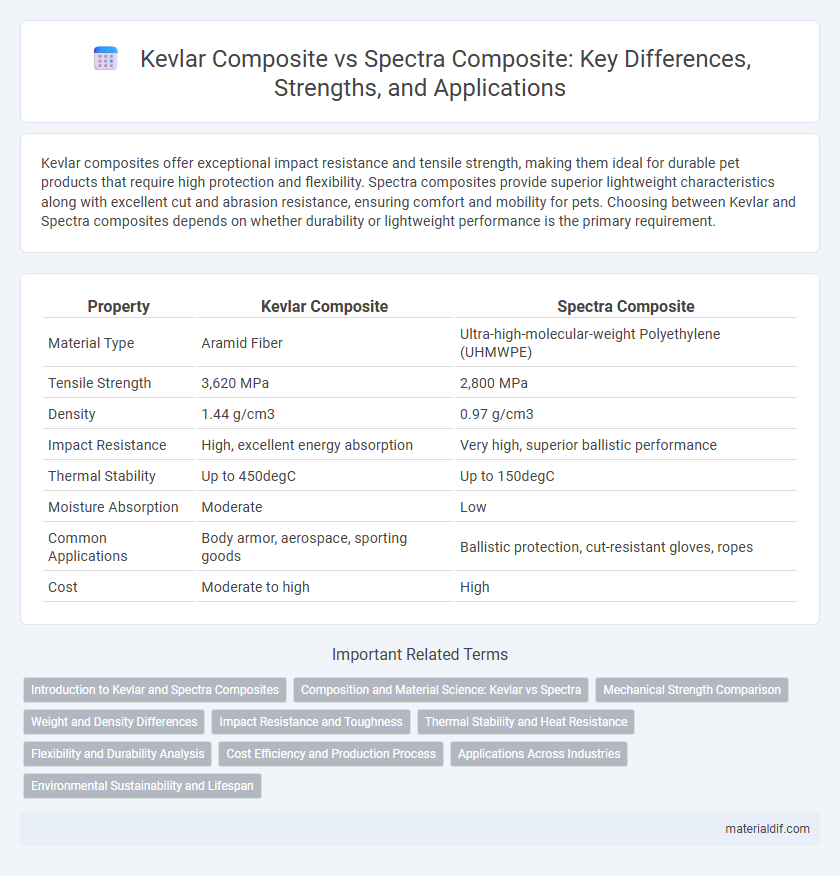

Kevlar composites offer exceptional impact resistance and tensile strength, making them ideal for durable pet products that require high protection and flexibility. Spectra composites provide superior lightweight characteristics along with excellent cut and abrasion resistance, ensuring comfort and mobility for pets. Choosing between Kevlar and Spectra composites depends on whether durability or lightweight performance is the primary requirement.

Table of Comparison

| Property | Kevlar Composite | Spectra Composite |

|---|---|---|

| Material Type | Aramid Fiber | Ultra-high-molecular-weight Polyethylene (UHMWPE) |

| Tensile Strength | 3,620 MPa | 2,800 MPa |

| Density | 1.44 g/cm3 | 0.97 g/cm3 |

| Impact Resistance | High, excellent energy absorption | Very high, superior ballistic performance |

| Thermal Stability | Up to 450degC | Up to 150degC |

| Moisture Absorption | Moderate | Low |

| Common Applications | Body armor, aerospace, sporting goods | Ballistic protection, cut-resistant gloves, ropes |

| Cost | Moderate to high | High |

Introduction to Kevlar and Spectra Composites

Kevlar composites are renowned for their exceptional tensile strength and thermal stability, making them ideal for ballistic and aerospace applications. Spectra composites, made from ultra-high-molecular-weight polyethylene fibers, offer superior impact resistance and lightweight properties favored in personal armor and marine industries. Both materials provide advanced durability and performance but differ significantly in fiber structure and environmental resistance.

Composition and Material Science: Kevlar vs Spectra

Kevlar composite is primarily composed of aramid fibers known for their high tensile strength and thermal stability, making them resistant to heat and abrasion. Spectra composite consists of ultra-high-molecular-weight polyethylene (UHMWPE) fibers, characterized by exceptional impact resistance and low density, providing superior ballistic performance while being lighter than Kevlar. Material science analysis reveals Kevlar's aromatic polyamide structure offers rigidity and thermal resistance, whereas Spectra's polyethylene chains provide flexibility and higher energy absorption, influencing their respective applications in protective gear and ballistic armor.

Mechanical Strength Comparison

Kevlar composites exhibit superior tensile strength and impact resistance compared to Spectra composites, making them ideal for high-stress applications. Kevlar fibers possess a tensile strength of approximately 3,620 MPa, whereas Spectra fibers have a tensile strength near 3,000 MPa. The enhanced stiffness and energy absorption capabilities of Kevlar composites contribute to their widespread use in ballistic protection and aerospace components.

Weight and Density Differences

Kevlar composites exhibit a density of approximately 1.44 g/cm3, while Spectra composites have a lower density near 0.97 g/cm3, making Spectra significantly lighter. The weight difference directly impacts applications requiring high strength-to-weight ratios, where Spectra composites offer superior performance due to their reduced mass. Both materials provide high tensile strength, but Spectra composites are preferred when minimizing weight is critical without sacrificing durability.

Impact Resistance and Toughness

Kevlar composites exhibit superior impact resistance due to their high tensile strength and energy absorption capabilities, making them ideal for ballistic protection and aerospace applications. Spectra composites, while lighter and offering excellent toughness, often show lower impact resistance under high-velocity conditions compared to Kevlar. The molecular structure of Kevlar fibers provides enhanced durability and resistance to penetration, giving it an advantage in scenarios demanding extreme toughness.

Thermal Stability and Heat Resistance

Kevlar composites exhibit superior thermal stability with a decomposition temperature around 500degC, outperforming Spectra composites that typically degrade near 190degC. The aromatic polyamide structure of Kevlar provides enhanced heat resistance, making it ideal for applications requiring prolonged exposure to high temperatures. Spectra composites, composed of polyethylene fibers, offer lower thermal endurance but excel in impact resistance and lightweight performance.

Flexibility and Durability Analysis

Kevlar composites exhibit superior durability with high tensile strength and excellent impact resistance, making them ideal for applications demanding long-term structural integrity. Spectra composites offer enhanced flexibility due to their ultra-high-molecular-weight polyethylene fibers, allowing better conformity to dynamic shapes and movements. Comparative analysis shows Kevlar's higher resistance to heat and abrasion, while Spectra provides more versatility in flexible applications where lightweight and pliability are critical.

Cost Efficiency and Production Process

Kevlar composite offers higher cost efficiency compared to Spectra composite due to its lower raw material cost and established manufacturing processes. The production of Kevlar composites benefits from widely available textile fabrication techniques such as weaving and molding, enabling scalable and consistent output. In contrast, Spectra composite production involves more complex gel spinning and processing steps, which increases overall production expenses.

Applications Across Industries

Kevlar composite materials excel in automotive and aerospace industries for their exceptional tensile strength and heat resistance, enabling lightweight yet durable components. Spectra composite is widely favored in marine and ballistic armor applications due to its superior impact absorption and corrosion resistance. Both composites find extensive use in protective gear, with Kevlar dominating in helmets and body armor and Spectra preferred for stab-resistant vests and flexible protective fabrics.

Environmental Sustainability and Lifespan

Kevlar composites exhibit high environmental sustainability due to their long lifespan and resistance to degradation, which reduces the frequency of replacement and waste generation. Spectra composites, while also durable, tend to have a shorter lifespan under UV exposure and environmental stress, leading to more frequent disposal and environmental impact. Lifecycle assessments indicate Kevlar's superior performance in reducing carbon footprint over time compared to Spectra-based composites.

Kevlar composite vs Spectra composite Infographic

materialdif.com

materialdif.com