Kevlar yarn consists of continuous fibers used primarily in weaving and knitting to create durable fabrics with high tensile strength, ideal for heavy-duty applications. Kevlar thread, on the other hand, is a spun or twisted form of Kevlar yarn designed for sewing and stitching, providing exceptional resistance to abrasion and heat in finished products. Both materials offer unmatched durability and protection, but Kevlar yarn is favored for fabric production, while Kevlar thread is essential for assembling Kevlar-based gear.

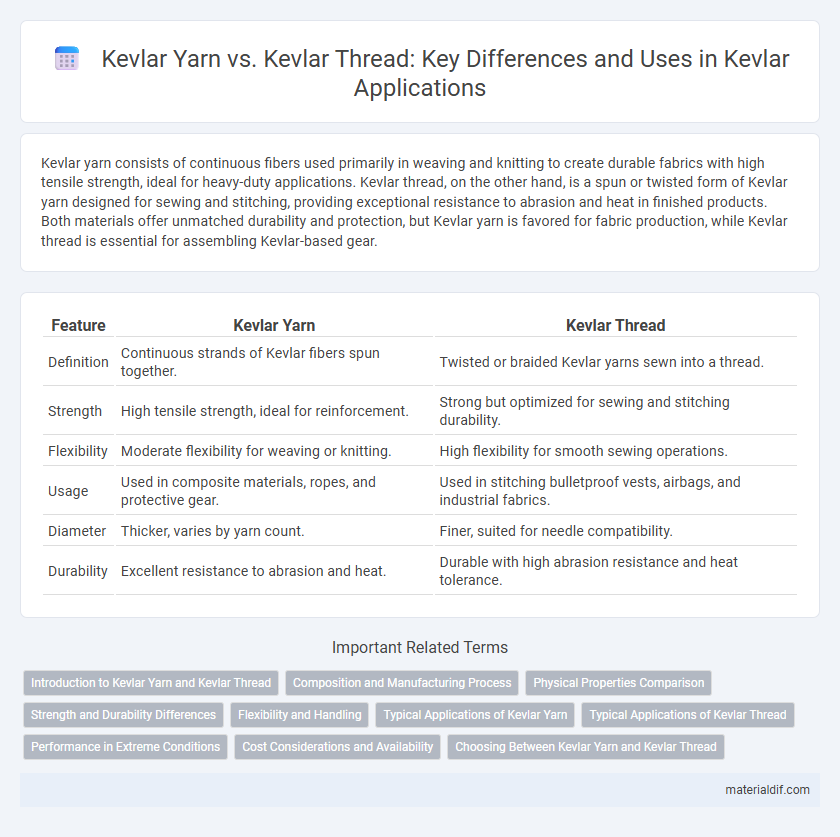

Table of Comparison

| Feature | Kevlar Yarn | Kevlar Thread |

|---|---|---|

| Definition | Continuous strands of Kevlar fibers spun together. | Twisted or braided Kevlar yarns sewn into a thread. |

| Strength | High tensile strength, ideal for reinforcement. | Strong but optimized for sewing and stitching durability. |

| Flexibility | Moderate flexibility for weaving or knitting. | High flexibility for smooth sewing operations. |

| Usage | Used in composite materials, ropes, and protective gear. | Used in stitching bulletproof vests, airbags, and industrial fabrics. |

| Diameter | Thicker, varies by yarn count. | Finer, suited for needle compatibility. |

| Durability | Excellent resistance to abrasion and heat. | Durable with high abrasion resistance and heat tolerance. |

Introduction to Kevlar Yarn and Kevlar Thread

Kevlar yarn consists of continuous fibers spun together to create a strong, flexible material ideal for weaving and knitting applications, offering high tensile strength and resistance to heat and abrasion. Kevlar thread is made by twisting multiple Kevlar yarns, producing a durable, lightweight sewing or stitching material crucial for reinforcing textiles and protective gear. Both Kevlar yarn and thread maximize the exceptional properties of para-aramid fibers, with yarn serving as a raw material and thread tailored for precise industrial sewing needs.

Composition and Manufacturing Process

Kevlar yarn consists of continuous filaments made from poly-paraphenylene terephthalamide fibers, produced through a liquid crystal polymer spinning process that aligns molecules for enhanced strength. Kevlar thread, on the other hand, is created by twisting multiple Kevlar yarns together, increasing tensile strength and durability for sewing applications. The manufacturing process of Kevlar thread involves additional steps such as twisting, plying, and sometimes coating, distinguishing it from the yarn's more straightforward filament spinning technique.

Physical Properties Comparison

Kevlar yarn consists of extremely strong, continuous filaments that offer high tensile strength and exceptional flexibility, making it ideal for applications requiring durability and resistance to abrasion. Kevlar thread, on the other hand, is composed of tightly spun yarns, providing enhanced stitch strength and reduced fraying, which is crucial for sewing heavy-duty fabrics. The physical properties of Kevlar yarn emphasize fiber strength and elongation, whereas Kevlar thread focuses on thickness, uniformity, and tensile strength suitable for industrial stitching.

Strength and Durability Differences

Kevlar yarn exhibits higher tensile strength and flexibility compared to Kevlar thread, making it ideal for applications requiring superior load-bearing capacity. The continuous filament structure of Kevlar yarn enhances its durability and resistance to abrasion, whereas Kevlar thread, being spun from shorter fibers, tends to have slightly lower strength and resilience. These differences impact performance in critical industries like aerospace and ballistic protection, where Kevlar yarn's enhanced durability ensures extended lifespan under extreme stress.

Flexibility and Handling

Kevlar yarn offers greater flexibility due to its finer fibers, making it ideal for applications requiring intricate weaving and lightweight, pliable materials. Kevlar thread, while slightly stiffer, provides enhanced strength and durability for heavy-duty stitching and high-stress seams. The choice between Kevlar yarn and thread depends on the balance needed between flexibility and tensile strength in the intended use.

Typical Applications of Kevlar Yarn

Kevlar yarn is extensively used in the manufacturing of high-strength ropes, ballistic fibers for body armor, and composite reinforcements due to its exceptional tensile strength and lightweight properties. This yarn serves as the core material in aerospace and automotive industries where durability and resistance to impact are critical. Kevlar yarn's flexibility and heat resistance make it ideal for protective apparel and industrial fabrics requiring superior performance under extreme conditions.

Typical Applications of Kevlar Thread

Kevlar thread is commonly used in applications requiring high tensile strength and flexibility, such as stitching reinforcement in protective gear, military apparel, and industrial gloves. Its fine, durable fibers make it ideal for sewing materials exposed to extreme stress, heat, and abrasion. Kevlar thread also finds extensive use in aerospace and automotive industries for assembling lightweight composites and protective covers.

Performance in Extreme Conditions

Kevlar yarn offers superior tensile strength and flexibility compared to Kevlar thread, making it ideal for applications requiring high durability under extreme stress and temperature fluctuations. Kevlar yarn's tightly spun fibers provide enhanced resistance to abrasion, impact, and chemical exposure, ensuring consistent performance in harsh environments such as ballistic protection and aerospace components. Kevlar thread, while strong, is generally less resilient in extreme conditions due to its thinner, less dense construction, limiting its use to lighter-duty stitching and repairs.

Cost Considerations and Availability

Kevlar yarn generally costs more than Kevlar thread due to its higher tensile strength and specialized production process, making it the preferred choice for high-performance applications. Kevlar thread, being more widely available and less expensive, is suitable for general stitching and light-duty uses where extreme durability is not critical. Availability of Kevlar yarn can be limited due to its niche market and specific manufacturing requirements, whereas Kevlar thread is more readily stocked by suppliers serving broader textile and industrial sectors.

Choosing Between Kevlar Yarn and Kevlar Thread

Kevlar yarn consists of long continuous fibers, offering superior tensile strength and flexibility, making it ideal for high-performance applications like ballistic protection and advanced composites. Kevlar thread, on the other hand, is composed of shorter twisted fibers, providing enhanced durability and knot security suitable for sewing heavy-duty fabrics and industrial stitching. Selecting between Kevlar yarn and Kevlar thread depends on whether strength and flexibility or stitching durability and resistance to abrasion are the primary requirements for the project.

Kevlar Yarn vs Kevlar Thread Infographic

materialdif.com

materialdif.com