Kevlar aramid fiber offers superior tensile strength and abrasion resistance compared to Nomex aramid fiber, making it ideal for high-impact pet protection gear. Nomex aramid fiber excels in thermal stability and flame resistance, providing enhanced safety in heat-prone environments for pets. Choosing between Kevlar and Nomex depends on whether durability or heat resistance is the priority in pet-related applications.

Table of Comparison

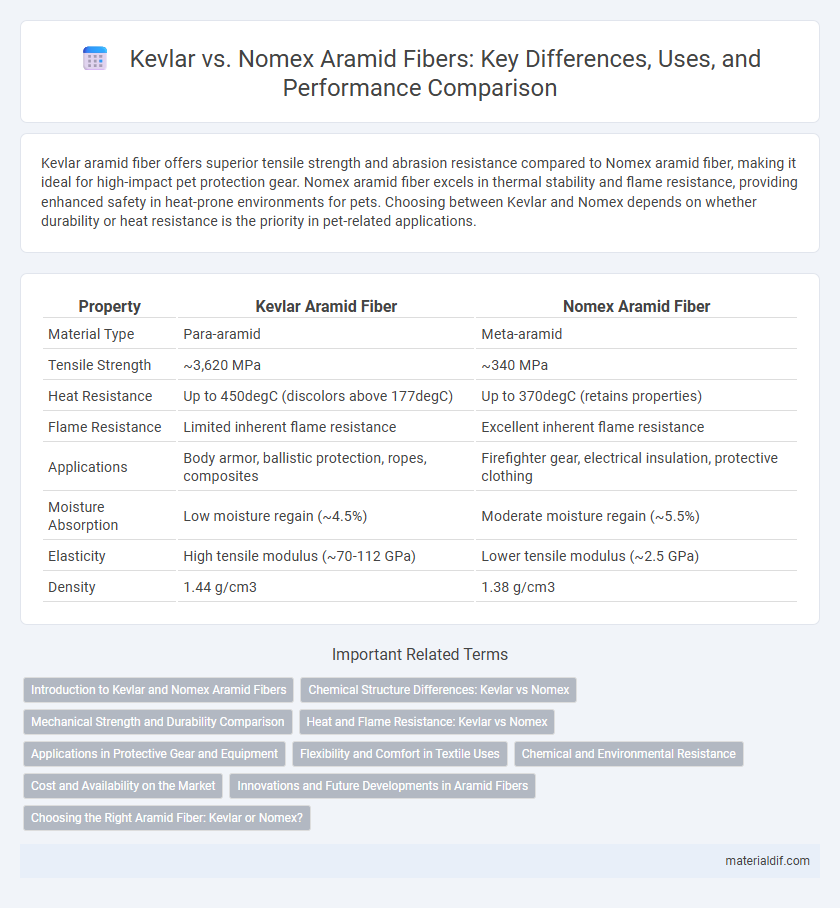

| Property | Kevlar Aramid Fiber | Nomex Aramid Fiber |

|---|---|---|

| Material Type | Para-aramid | Meta-aramid |

| Tensile Strength | ~3,620 MPa | ~340 MPa |

| Heat Resistance | Up to 450degC (discolors above 177degC) | Up to 370degC (retains properties) |

| Flame Resistance | Limited inherent flame resistance | Excellent inherent flame resistance |

| Applications | Body armor, ballistic protection, ropes, composites | Firefighter gear, electrical insulation, protective clothing |

| Moisture Absorption | Low moisture regain (~4.5%) | Moderate moisture regain (~5.5%) |

| Elasticity | High tensile modulus (~70-112 GPa) | Lower tensile modulus (~2.5 GPa) |

| Density | 1.44 g/cm3 | 1.38 g/cm3 |

Introduction to Kevlar and Nomex Aramid Fibers

Kevlar aramid fiber is renowned for its exceptional tensile strength, lightweight properties, and high resistance to impact, making it ideal for ballistic and protective applications. Nomex aramid fiber offers superior thermal resistance and flame retardancy, excelling in heat and fire protection for firefighting gear and industrial safety wear. Both fibers belong to the aramid family but serve distinct functions based on their unique molecular structures and performance characteristics.

Chemical Structure Differences: Kevlar vs Nomex

Kevlar and Nomex are both aramid fibers with distinct chemical structures that define their properties and applications. Kevlar features a rigid, rod-like molecular structure with para-oriented aromatic polyamide chains, providing exceptional tensile strength and thermal stability ideal for ballistic and protective gear. In contrast, Nomex has a meta-oriented aromatic polyamide structure, resulting in enhanced flame resistance and thermal insulation, commonly used in firefighting apparel and electrical insulation.

Mechanical Strength and Durability Comparison

Kevlar aramid fiber exhibits superior tensile strength and higher modulus compared to Nomex, making it more effective in applications demanding exceptional mechanical strength. Kevlar's enhanced durability arises from its crystalline polymer structure, which provides excellent resistance to abrasion, impact, and fatigue under extreme conditions. Nomex, while offering good thermal and flame resistance, demonstrates lower mechanical strength and less abrasion resistance, limiting its use where high tensile loading and long-term wear are critical.

Heat and Flame Resistance: Kevlar vs Nomex

Kevlar aramid fiber offers excellent tensile strength and mechanical durability but provides moderate heat resistance, typically withstanding continuous exposure up to 400degC (752degF). Nomex aramid fiber, in contrast, excels in heat and flame resistance, maintaining structural integrity at temperatures up to 370degC (698degF) while resisting combustion and thermal degradation more effectively. Nomex is preferred for applications requiring superior flame retardancy and thermal protection, whereas Kevlar is chosen for high-strength, impact-resistant needs.

Applications in Protective Gear and Equipment

Kevlar aramid fiber excels in protective gear due to its high tensile strength and cut resistance, making it ideal for bulletproof vests and motorcycle apparel. Nomex aramid fiber is favored for flame-resistant clothing and firefighting gear because of its superior thermal stability and heat resistance. Both fibers are essential in safety equipment, with Kevlar enhancing impact protection while Nomex provides critical flame retardancy in hazardous environments.

Flexibility and Comfort in Textile Uses

Kevlar aramid fiber offers superior strength and durability but is relatively less flexible and breathable compared to Nomex, which provides enhanced comfort and pliability for textile applications requiring extended wear. Nomex fibers exhibit better moisture-wicking properties and softness, making them ideal for protective clothing where flexibility and thermal comfort are critical. Choosing between Kevlar and Nomex depends on the balance of protection needs versus wearer comfort in demanding environments.

Chemical and Environmental Resistance

Kevlar aramid fiber exhibits exceptional chemical resistance against organic solvents, oils, and fuels, making it highly durable in harsh industrial environments, whereas Nomex aramid fiber offers superior resistance to strong acids, alkalis, and oxidizing agents. Both fibers demonstrate excellent thermal stability, but Kevlar's molecular structure provides greater toughness and abrasion resistance, while Nomex excels in flame retardancy and chemical inertness under extreme conditions. Environmental degradation for Kevlar is minimal in outdoor applications, unlike Nomex which can undergo photo-oxidative breakdown more readily in prolonged UV exposure.

Cost and Availability on the Market

Kevlar aramid fiber generally carries a higher cost than Nomex due to its superior tensile strength and widespread use in ballistic protection, impacting budget considerations for large-scale applications. Nomex is more readily available and cost-effective, making it a preferred choice for thermal and fire-resistant clothing in industries like firefighting and aviation. Market availability for both fibers is high, but Kevlar's specialized applications and licensing agreements can limit access compared to the more broadly distributed Nomex.

Innovations and Future Developments in Aramid Fibers

Kevlar aramid fiber exhibits superior tensile strength and durability, making it a preferred choice for ballistic protection and industrial applications, while Nomex aramid fiber excels in thermal stability and flame resistance, ideal for firefighting and aerospace environments. Innovations in aramid fibers are focusing on enhancing hybrid materials that combine Kevlar's mechanical strength with Nomex's heat resistance to create multifunctional composites. Future developments aim to optimize molecular structures for increased lightweight performance, eco-friendly production processes, and improved compatibility with smart textiles and advanced nanomaterials.

Choosing the Right Aramid Fiber: Kevlar or Nomex?

Kevlar aramid fiber offers exceptional tensile strength and cut resistance, making it ideal for bulletproof vests, ballistic helmets, and high-performance protective gear, while Nomex aramid fiber excels in thermal stability and flame resistance, preferred for firefighter suits and aerospace applications. Selecting the right aramid fiber depends on the primary requirement: Kevlar for impact and abrasion protection, Nomex for heat and fire resistance. Understanding the mechanical and thermal properties of both materials ensures optimal performance in safety and industrial environments.

Kevlar aramid fiber vs Nomex aramid fiber Infographic

materialdif.com

materialdif.com