Kevlar weave offers a tightly interlaced structure that provides superior tensile strength and durability, making it ideal for high-impact protection in pet gear. Kevlar felt, on the other hand, features a non-woven, matted composition that delivers enhanced flexibility and shock absorption, suitable for comfort-focused applications. Choosing between Kevlar weave and Kevlar felt depends on whether strength or cushioning is the primary requirement in pet protective equipment.

Table of Comparison

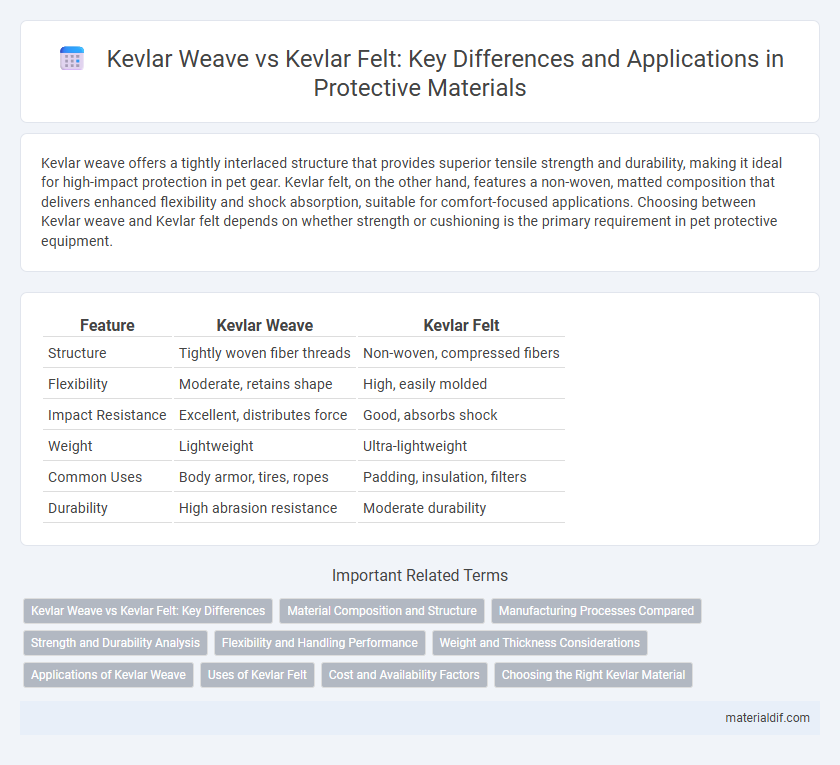

| Feature | Kevlar Weave | Kevlar Felt |

|---|---|---|

| Structure | Tightly woven fiber threads | Non-woven, compressed fibers |

| Flexibility | Moderate, retains shape | High, easily molded |

| Impact Resistance | Excellent, distributes force | Good, absorbs shock |

| Weight | Lightweight | Ultra-lightweight |

| Common Uses | Body armor, tires, ropes | Padding, insulation, filters |

| Durability | High abrasion resistance | Moderate durability |

Kevlar Weave vs Kevlar Felt: Key Differences

Kevlar weave consists of interlaced fibers forming a durable fabric known for high tensile strength and superior flexibility, making it ideal for applications requiring abrasion resistance and impact protection. Kevlar felt, on the other hand, is a non-woven mat of compressed fibers that offers excellent thermal insulation and padding due to its dense, cushioned structure. The key differences lie in durability and flexibility, with Kevlar weave providing enhanced mechanical strength, while Kevlar felt excels in shock absorption and heat resistance.

Material Composition and Structure

Kevlar weave consists of interlaced fibers arranged in a tight, grid-like pattern, providing high tensile strength and flexibility ideal for ballistic protection and high-performance textiles. Kevlar felt, on the other hand, is made from randomly oriented fibers bonded together, resulting in a dense, non-woven structure that offers superior impact absorption and thermal insulation. The structural differences in material composition between the woven and felt forms determine their specific mechanical properties and applications in safety gear and industrial uses.

Manufacturing Processes Compared

Kevlar weave involves interlacing fibers in a tight, grid-like pattern that enhances tensile strength and flexibility, making it ideal for ballistic and protective applications. Kevlar felt, produced by bonding fibers into a dense mat through needle-punching or heat pressing, offers superior insulation and impact absorption due to its random fiber orientation. Manufacturing Kevlar weave requires precise looms and controlled tension, whereas Kevlar felt production relies on mechanical felting techniques, impacting the material's structural characteristics and performance.

Strength and Durability Analysis

Kevlar weave exhibits higher tensile strength and greater resistance to abrasion compared to Kevlar felt, making it ideal for applications requiring maximum durability under dynamic stress. Kevlar felt, although less strong, offers superior impact absorption and flexibility, suitable for cushioning and insulation purposes. Strength and durability analysis confirms that woven Kevlar outperforms felt in load-bearing scenarios, while felt excels in conformability and energy dissipation.

Flexibility and Handling Performance

Kevlar weave offers superior flexibility and enhanced handling performance due to its interlaced fiber structure, allowing it to conform more easily to complex shapes and movements. In contrast, Kevlar felt provides a stiffer and less pliable material, limiting its adaptability but offering increased thickness and impact resistance. The choice between Kevlar weave and felt should prioritize flexibility requirements, with woven Kevlar excelling in applications demanding agility and comfort.

Weight and Thickness Considerations

Kevlar weave typically offers a balanced combination of strength and flexibility with moderate weight and thickness, making it suitable for applications requiring durability without excessive bulk. Kevlar felt, on the other hand, is generally thicker and heavier due to its dense, non-woven fiber structure, providing enhanced impact absorption but potentially limiting flexibility and increasing overall weight. Choosing between Kevlar weave and Kevlar felt depends on specific weight constraints and thickness requirements dictated by the intended protective or structural use.

Applications of Kevlar Weave

Kevlar weave is widely used in high-performance applications such as ballistic armor, aerospace components, and sporting goods due to its superior tensile strength and abrasion resistance. The tight interlacing of Kevlar fibers in the weave structure provides enhanced durability and flexibility, making it ideal for protective gear and composite materials. Compared to Kevlar felt, which offers better insulation and cushioning, Kevlar weave excels in structural integrity and load-bearing performance.

Uses of Kevlar Felt

Kevlar felt offers superior sound absorption and thermal insulation compared to Kevlar weave, making it ideal for automotive and aerospace applications where noise reduction and heat resistance are critical. It is commonly used in gaskets, seals, and padding to provide durable protection against abrasion and impact. Its fibrous structure allows for flexibility and easier molding into complex shapes, expanding its utility in protective equipment and industrial filtration systems.

Cost and Availability Factors

Kevlar weave generally incurs higher costs due to its complex fabrication process requiring precise tension and alignment, whereas Kevlar felt is more economical because it involves a simpler matting technique. Availability of Kevlar weave can be limited by specialized manufacturing facilities and longer lead times, while Kevlar felt is more readily accessible with broader production capabilities. Cost-efficiency favors Kevlar felt in large-scale applications, but Kevlar weave remains preferred for high-performance products demanding enhanced strength and durability.

Choosing the Right Kevlar Material

Kevlar weave offers superior tensile strength and durability, making it ideal for applications requiring high impact resistance and structural support, such as ballistic vests and aerospace components. Kevlar felt, characterized by its non-woven, fibrous structure, provides enhanced flexibility and thermal insulation, suitable for noise reduction and heat shielding in automotive and industrial settings. Selecting between Kevlar weave and felt depends on balancing the need for mechanical strength versus flexibility and thermal properties tailored to specific application demands.

Kevlar weave vs Kevlar felt Infographic

materialdif.com

materialdif.com