Kevlar lamination offers superior strength and durability compared to plastic lamination, making it ideal for pet products that require enhanced puncture and tear resistance. While plastic lamination provides a lightweight and cost-effective option, it lacks the high-performance protection and longevity that Kevlar delivers. Choosing Kevlar lamination ensures robust safety and extended lifespan for pet accessories exposed to rough conditions.

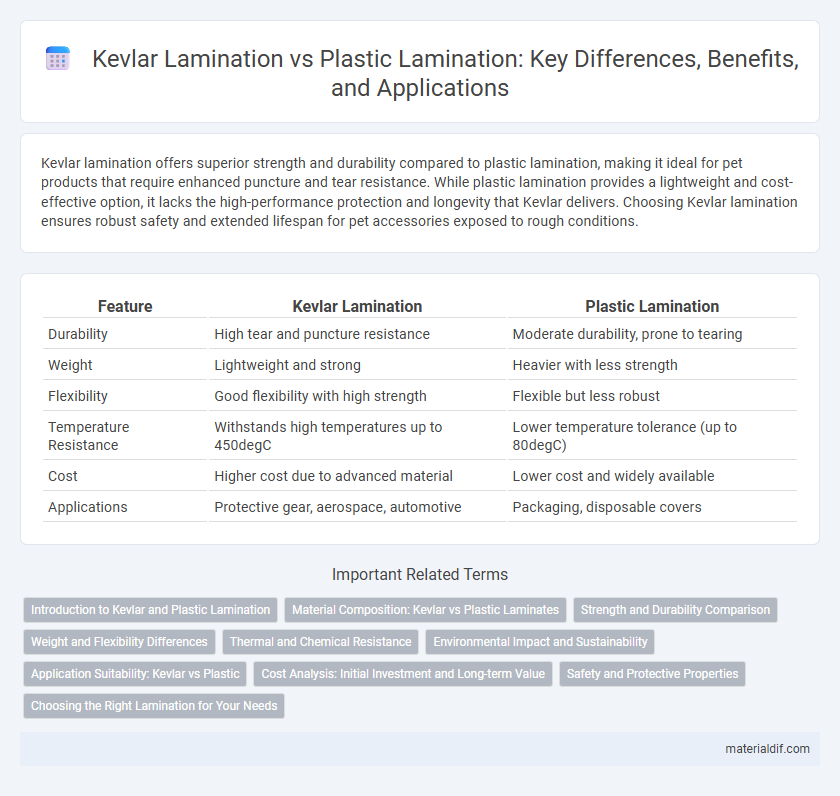

Table of Comparison

| Feature | Kevlar Lamination | Plastic Lamination |

|---|---|---|

| Durability | High tear and puncture resistance | Moderate durability, prone to tearing |

| Weight | Lightweight and strong | Heavier with less strength |

| Flexibility | Good flexibility with high strength | Flexible but less robust |

| Temperature Resistance | Withstands high temperatures up to 450degC | Lower temperature tolerance (up to 80degC) |

| Cost | Higher cost due to advanced material | Lower cost and widely available |

| Applications | Protective gear, aerospace, automotive | Packaging, disposable covers |

Introduction to Kevlar and Plastic Lamination

Kevlar lamination involves bonding layers of Kevlar fabric with resins to create a composite material known for exceptional tensile strength and impact resistance, commonly used in bulletproof vests and aerospace components. Plastic lamination typically uses polyethylene or polypropylene films to enhance durability, moisture resistance, and flexibility in packaging, but lacks the structural reinforcement provided by Kevlar. Kevlar's high-performance fibers significantly outperform plastic laminates in strength and thermal stability, making it ideal for protective applications where mechanical toughness is critical.

Material Composition: Kevlar vs Plastic Laminates

Kevlar lamination consists of aramid fibers known for exceptional tensile strength, heat resistance, and lightweight properties, making it ideal for protective applications. Plastic laminates, typically composed of polymers like polyethylene or polypropylene, offer flexibility and moisture resistance but lack the high strength and thermal stability of Kevlar. The molecular structure of Kevlar provides superior durability and impact resistance compared to the comparatively softer and less resilient plastic laminates.

Strength and Durability Comparison

Kevlar lamination offers significantly higher tensile strength and superior impact resistance compared to plastic lamination, making it ideal for protective gear and industrial applications. The cross-linked polymer chains in Kevlar contribute to exceptional durability and resistance to abrasion, heat, and chemical degradation, whereas plastic laminates tend to weaken under prolonged stress and environmental exposure. Kevlar's lightweight composition combined with its robustness ensures longer lifespan and enhanced performance in demanding conditions compared to traditional plastic laminates.

Weight and Flexibility Differences

Kevlar lamination offers superior strength-to-weight ratio compared to plastic lamination, making it significantly lighter while maintaining high durability. Its unique fiber structure grants enhanced flexibility, allowing it to conform better to complex shapes without compromising protection. In contrast, plastic lamination tends to be heavier and less flexible, which can limit its application in lightweight, high-performance environments.

Thermal and Chemical Resistance

Kevlar lamination offers superior thermal resistance, maintaining structural integrity at temperatures up to 450degC, compared to typical plastic laminations that degrade around 100-150degC. Chemically, Kevlar resists a wide range of solvents, acids, and bases without swelling or weakening, whereas plastic laminates often suffer from chemical degradation and reduced lifespan. This makes Kevlar lamination ideal for applications requiring high durability in extreme thermal and chemical environments.

Environmental Impact and Sustainability

Kevlar lamination offers superior environmental benefits compared to plastic lamination due to its durability and resistance to degradation, reducing the frequency of replacement and waste generation. Plastic lamination, often derived from petrochemicals, contributes significantly to pollution and landfill accumulation because of its non-biodegradable nature. Kevlar's sustainable properties include a longer lifecycle and potential for recycling, making it a more eco-friendly choice in applications requiring strong, lightweight barriers.

Application Suitability: Kevlar vs Plastic

Kevlar lamination offers superior impact resistance and high tensile strength, making it ideal for applications requiring enhanced durability such as ballistic armor, protective gloves, and aerospace components. Plastic lamination, while providing excellent moisture resistance and flexibility, is more suitable for packaging, graphic overlays, and lightweight protective covers. The choice between Kevlar and plastic lamination depends on the specific performance requirements, with Kevlar excelling in high-stress, safety-critical environments and plastic favored for cost-effective, everyday protection.

Cost Analysis: Initial Investment and Long-term Value

Kevlar lamination involves a higher initial investment due to the cost of aramid fibers and specialized bonding processes, whereas plastic lamination typically requires lower upfront expenses with commonly available materials. Over the long term, Kevlar lamination delivers superior durability, enhanced tensile strength, and excellent resistance to heat and abrasion, which can reduce replacement and maintenance costs significantly. Plastic lamination might incur frequent repairs or replacements in harsh conditions, ultimately increasing lifecycle expenses compared to Kevlar.

Safety and Protective Properties

Kevlar lamination offers superior safety and protective properties compared to plastic lamination due to its high tensile strength and exceptional resistance to impact and abrasion. Kevlar's ability to absorb and dissipate energy significantly enhances cut and puncture resistance, making it ideal for body armor and industrial safety applications. Plastic lamination, while providing moisture and chemical resistance, lacks the structural durability needed for high-risk environments where protection against physical hazards is critical.

Choosing the Right Lamination for Your Needs

Kevlar lamination offers superior strength, heat resistance, and durability compared to plastic lamination, making it ideal for applications requiring enhanced protection and longevity, such as protective gear and industrial uses. Plastic lamination provides cost-effective moisture and abrasion resistance, suitable for everyday packaging and decorative purposes where extreme toughness is not critical. Evaluating factors like environmental exposure, mechanical stress, and budget constraints is essential when choosing between Kevlar and plastic lamination for your project.

Kevlar Lamination vs Plastic Lamination Infographic

materialdif.com

materialdif.com