Kevlar(r) pet products offer exceptional cut resistance, providing robust protection against sharp objects and preventing injuries during pet activities. Their inherent fire retardant properties enhance safety by reducing the risk of ignition and flame spread, making them ideal for environments where both flame exposure and sharp hazards exist. Combining fire retardancy with cut resistance ensures durable and reliable protection for pets in demanding conditions.

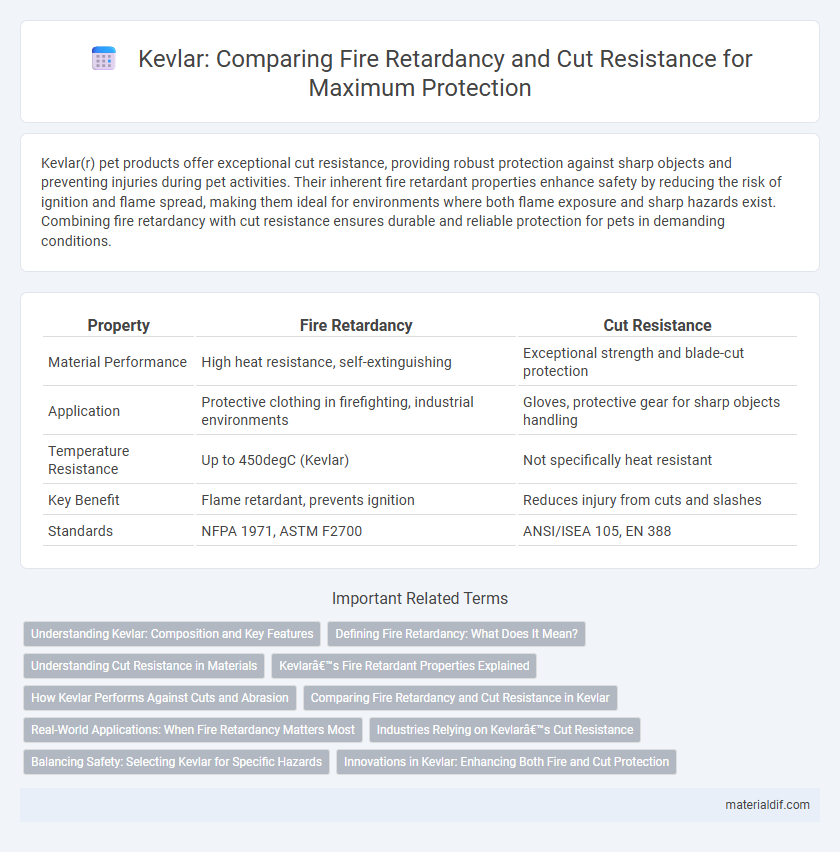

Table of Comparison

| Property | Fire Retardancy | Cut Resistance |

|---|---|---|

| Material Performance | High heat resistance, self-extinguishing | Exceptional strength and blade-cut protection |

| Application | Protective clothing in firefighting, industrial environments | Gloves, protective gear for sharp objects handling |

| Temperature Resistance | Up to 450degC (Kevlar) | Not specifically heat resistant |

| Key Benefit | Flame retardant, prevents ignition | Reduces injury from cuts and slashes |

| Standards | NFPA 1971, ASTM F2700 | ANSI/ISEA 105, EN 388 |

Understanding Kevlar: Composition and Key Features

Kevlar, a para-aramid synthetic fiber, is renowned for its exceptional cut resistance due to its high tensile strength and molecular structure designed to absorb impact energy. Its fire retardancy stems from inherent thermal stability, allowing Kevlar to maintain integrity under high temperatures without melting or dripping. Understanding Kevlar's composition--characterized by rigid aromatic polyamide chains--clarifies its dual capability to provide robust cut protection while resisting flames in demanding applications.

Defining Fire Retardancy: What Does It Mean?

Fire retardancy refers to the ability of a material, like Kevlar, to resist ignition and prevent the spread of flames when exposed to fire. This property is critical in applications requiring enhanced safety, as it slows down combustion and reduces heat release. Kevlar's molecular structure provides inherent fire retardant characteristics by maintaining integrity and limiting damage in high-temperature environments.

Understanding Cut Resistance in Materials

Cut resistance in materials like Kevlar is measured by their ability to withstand sharp objects without tearing or penetrating, crucial for protective gear in hazardous environments. Kevlar fibers provide exceptional tensile strength and are engineered to absorb and disperse the energy from cuts, minimizing the risk of injury. Unlike fire retardancy, which focuses on resisting ignition and flame spread, cut resistance prioritizes durability against mechanical abrasion and slicing forces.

Kevlar’s Fire Retardant Properties Explained

Kevlar exhibits exceptional fire retardant properties due to its aromatic polyamide structure, which provides inherent thermal stability and resists ignition at temperatures exceeding 400degC. Unlike many synthetic fibers, Kevlar does not melt or drip when exposed to flame, maintaining structural integrity and reducing burn-through risk. Its fire retardancy combined with high cut resistance makes Kevlar an ideal material for protective apparel in firefighting and industrial safety applications.

How Kevlar Performs Against Cuts and Abrasion

Kevlar exhibits exceptional cut resistance due to its high tensile strength and tightly woven aramid fibers, making it ideal for protective gloves and body armor. Its abrasion resistance ensures durability in harsh environments, maintaining integrity under repeated friction and wear. While Kevlar provides limited inherent fire retardancy, its performance against cuts and abrasion remains its primary protective advantage in industrial and safety applications.

Comparing Fire Retardancy and Cut Resistance in Kevlar

Kevlar exhibits exceptional cut resistance due to its high tensile strength and tightly woven aramid fibers, making it ideal for applications requiring protection from sharp objects. However, while Kevlar has inherent flame resistance and can withstand high temperatures, its fire retardancy is not as robust as specialized fireproof materials engineered specifically for extreme heat exposure. Comparing both properties, Kevlar offers superior cut resistance but moderate fire retardancy, necessitating additional treatments or layering to enhance its performance against flames in high-risk environments.

Real-World Applications: When Fire Retardancy Matters Most

Kevlar's exceptional cut resistance makes it ideal for protective gloves and body armor where sharp object protection is critical, but in environments like firefighting or industrial welding, fire retardancy becomes the priority to prevent burns and improve safety. Fire retardant Kevlar fabrics are engineered to withstand high temperatures and flames, ensuring durability and protection in hazardous heat conditions. Choosing materials that balance these properties is crucial in sectors such as aerospace and military operations where exposure to both cuts and fire hazards may occur.

Industries Relying on Kevlar’s Cut Resistance

Kevlar's exceptional cut resistance is critical for industries such as aerospace, automotive manufacturing, and protective gear production, where materials must withstand sharp objects and abrasive surfaces to ensure safety and durability. While Kevlar also offers fire retardancy, its primary industrial value lies in preventing injuries and maintaining tool and equipment integrity against cuts and lacerations. Companies in construction, military, and law enforcement sectors depend heavily on Kevlar-reinforced products to enhance worker protection and operational reliability.

Balancing Safety: Selecting Kevlar for Specific Hazards

Kevlar offers exceptional cut resistance, making it ideal for applications requiring sharp object protection, while its inherent fire retardancy provides critical safety in high-temperature environments. Selecting Kevlar for specific hazards involves balancing its superior mechanical strength with appropriate thermal protection to enhance worker safety. Optimizing Kevlar usage ensures effective defense against both cuts and flames in industrial and firefighting gear.

Innovations in Kevlar: Enhancing Both Fire and Cut Protection

Kevlar innovations have significantly advanced fire retardancy and cut resistance by incorporating nanotechnology and chemical treatments that enhance its thermal stability without compromising its strength. New composite fibers combine Kevlar with flame-resistant polymers to maintain durability under extreme temperatures while providing superior abrasion resistance. These enhancements extend the material's application in protective gear for firefighters, military personnel, and industrial workers needing reliable multi-threat protection.

Fire Retardancy vs Cut Resistance Infographic

materialdif.com

materialdif.com