Kevlar weft and Kevlar warp are essential components in fabric construction, offering distinct strength and flexibility characteristics for pet products. The Kevlar warp yarns run lengthwise, providing superior tensile strength and durability, crucial for withstanding pulling forces and wear in pet harnesses or leashes. Conversely, Kevlar weft yarns run crosswise, enhancing the fabric's resistance to abrasion and tear, ensuring long-lasting protection for pets in rugged environments.

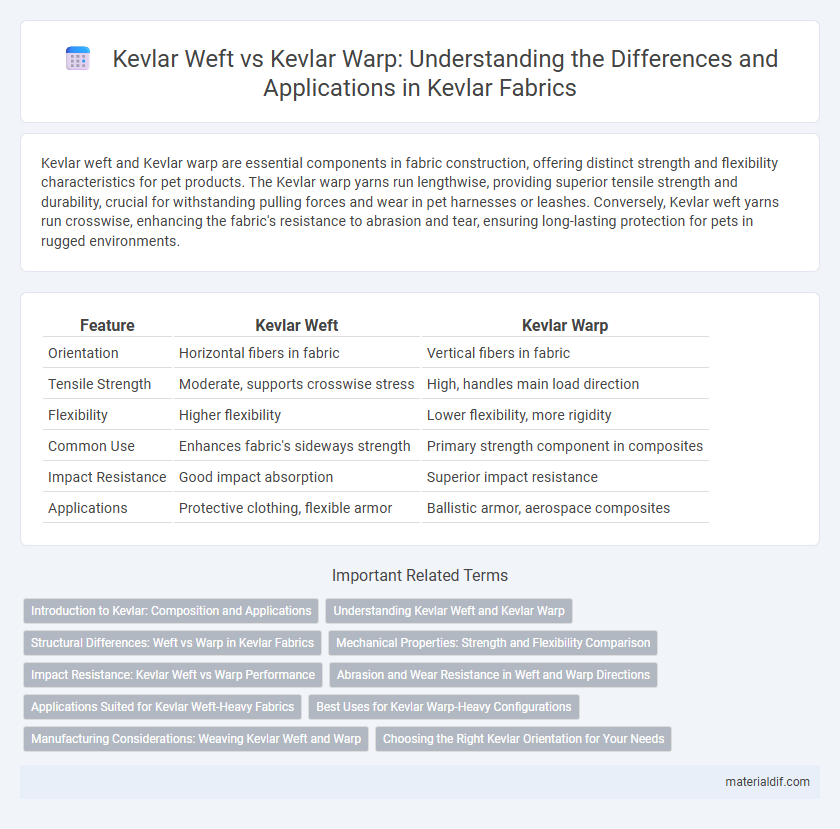

Table of Comparison

| Feature | Kevlar Weft | Kevlar Warp |

|---|---|---|

| Orientation | Horizontal fibers in fabric | Vertical fibers in fabric |

| Tensile Strength | Moderate, supports crosswise stress | High, handles main load direction |

| Flexibility | Higher flexibility | Lower flexibility, more rigidity |

| Common Use | Enhances fabric's sideways strength | Primary strength component in composites |

| Impact Resistance | Good impact absorption | Superior impact resistance |

| Applications | Protective clothing, flexible armor | Ballistic armor, aerospace composites |

Introduction to Kevlar: Composition and Applications

Kevlar is a para-aramid synthetic fiber renowned for its exceptional strength and heat resistance, composed primarily of poly-paraphenylene terephthalamide. In Kevlar fabric, the warp refers to the longitudinal fibers providing tensile strength, while the weft consists of transverse fibers contributing to flexibility and impact resistance. This unique combination enables Kevlar to be widely used in ballistic armor, aerospace components, and high-performance composites.

Understanding Kevlar Weft and Kevlar Warp

Kevlar weft and Kevlar warp refer to the two primary orientations of Kevlar fibers in woven fabric, where warp fibers run longitudinally and provide tensile strength, while weft fibers run horizontally and contribute to fabric stability and flexibility. Understanding Kevlar weft and warp is critical for optimizing the material's performance in ballistic protection, composites, and industrial applications, as the directional properties affect resistance to impact and tear. Proper alignment and tension of Kevlar warp and weft enhance the overall durability and structural integrity of advanced Kevlar textiles.

Structural Differences: Weft vs Warp in Kevlar Fabrics

Kevlar weft and Kevlar warp fibers differ structurally in orientation and load distribution within fabrics, where warp fibers run longitudinally providing primary tensile strength, while weft fibers run transversely offering lateral support and flexibility. The high tensile strength of Kevlar warp fibers enhances resistance to stretching and elongation, crucial for impact and ballistic protection applications. Weft fibers, though less tensioned, contribute to fabric stability and dimensional control, balancing the overall mechanical performance of Kevlar composites.

Mechanical Properties: Strength and Flexibility Comparison

Kevlar weft fibers provide enhanced flexibility due to their transverse orientation, allowing fabrics to better absorb impact forces, while Kevlar warp fibers contribute superior tensile strength along the fabric's length, crucial for load-bearing applications. The mechanical properties of Kevlar warp exhibit higher modulus and tensile strength compared to the weft, optimizing durability in ballistic and structural uses. Balancing Kevlar weft and warp alignments in composite materials maximizes both strength and flexibility, improving resistance to tearing and deformation under mechanical stress.

Impact Resistance: Kevlar Weft vs Warp Performance

Kevlar weft and warp fibers both contribute to impact resistance but exhibit distinct performance characteristics due to their orientation in the fabric. The Kevlar warp fibers, aligned longitudinally, provide superior tensile strength and resilience against high-velocity impacts, enhancing penetration resistance. Conversely, Kevlar weft fibers, woven transversely, offer improved energy dispersal across the fabric surface, increasing overall impact absorption and durability.

Abrasion and Wear Resistance in Weft and Warp Directions

Kevlar warp fibers provide superior tensile strength and abrasion resistance along the fabric's length, offering excellent durability against wear in high-stress applications. Kevlar weft fibers contribute enhanced flexibility and resistance to transverse abrasion, improving overall fabric performance in multi-directional wear scenarios. The combination of Kevlar weft and warp optimizes abrasion and wear resistance, ensuring extended lifespan and reliability under dynamic mechanical forces.

Applications Suited for Kevlar Weft-Heavy Fabrics

Kevlar weft-heavy fabrics provide enhanced cut and abrasion resistance, making them ideal for protective clothing, such as gloves and body armor, where lateral strength is critical. The denser weft yarns improve impact absorption and durability in applications subjected to frequent rubbing or scraping forces. These fabrics suit industrial safety gear, reinforced composites, and ballistic inserts requiring superior resistance across the weft direction.

Best Uses for Kevlar Warp-Heavy Configurations

Kevlar warp-heavy configurations excel in applications requiring maximum tensile strength and durability, such as ballistic vests, aerospace components, and high-performance sporting equipment. The warp threads, aligned parallel to the fabric's length, provide enhanced resistance to stretching and tearing under intense stress. This makes Kevlar warp-heavy weaves ideal for protective gear and structural reinforcements where directional strength is critical.

Manufacturing Considerations: Weaving Kevlar Weft and Warp

In manufacturing Kevlar fabric, the warp threads run longitudinally and must exhibit high tensile strength to withstand tension during weaving, while the weft threads run transversely and provide flexibility and impact resistance. Optimizing warp tension and weft insertion speed is critical to prevent yarn breakage and ensure uniform fabric density. Advanced weaving techniques, such as air-jet or rapier looms, improve the precision of Kevlar weft and warp integration, enhancing the material's performance in ballistic and protective applications.

Choosing the Right Kevlar Orientation for Your Needs

Kevlar warp fibers, aligned parallel to the fabric's length, provide superior tensile strength and resistance to linear stress, making them ideal for applications requiring high durability and load-bearing capacity. Kevlar weft fibers run perpendicular to the warp, contributing to fabric flexibility and impact resistance, suitable for gear that demands both strength and maneuverability. Selecting the right Kevlar orientation depends on balancing the need for tensile strength versus flexibility, with warp-oriented Kevlar favored in ballistic armor and weft-oriented Kevlar preferred in protective clothing and composites.

Kevlar Weft vs Kevlar Warp Infographic

materialdif.com

materialdif.com