Kevlar thread offers exceptional tensile strength and flexibility, making it ideal for precise stitching in high-durability pet products like harnesses and leashes. Kevlar fabric, composed of woven Kevlar threads, provides a robust, abrasion-resistant surface perfect for overall protective gear designed to withstand pet wear and tear. Choosing between Kevlar thread and Kevlar fabric depends on the product's need for either structural strength or comprehensive coverage in pet safety applications.

Table of Comparison

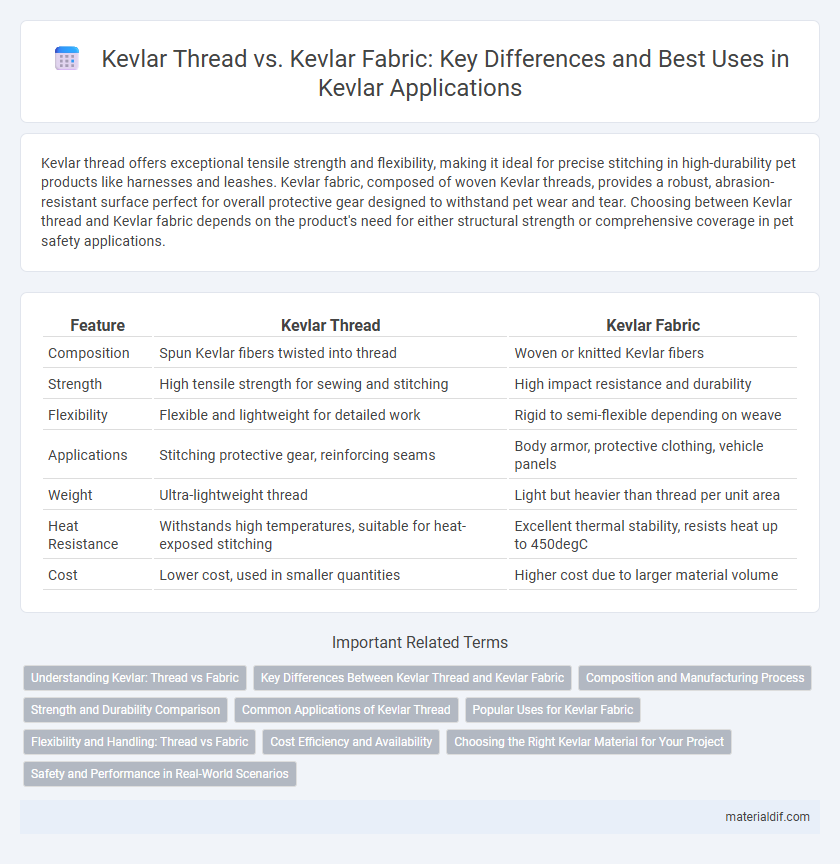

| Feature | Kevlar Thread | Kevlar Fabric |

|---|---|---|

| Composition | Spun Kevlar fibers twisted into thread | Woven or knitted Kevlar fibers |

| Strength | High tensile strength for sewing and stitching | High impact resistance and durability |

| Flexibility | Flexible and lightweight for detailed work | Rigid to semi-flexible depending on weave |

| Applications | Stitching protective gear, reinforcing seams | Body armor, protective clothing, vehicle panels |

| Weight | Ultra-lightweight thread | Light but heavier than thread per unit area |

| Heat Resistance | Withstands high temperatures, suitable for heat-exposed stitching | Excellent thermal stability, resists heat up to 450degC |

| Cost | Lower cost, used in smaller quantities | Higher cost due to larger material volume |

Understanding Kevlar: Thread vs Fabric

Kevlar thread consists of fine, continuous filaments used primarily for stitching, weaving, or reinforcing materials, offering high tensile strength and flexibility ideal for intricate applications. Kevlar fabric is woven or knitted from multiple Kevlar threads, forming a robust, lightweight textile that provides superior cut, heat, and abrasion resistance, widely used in body armor and protective gear. Understanding the distinction is crucial for selecting the appropriate Kevlar form based on the required strength, durability, and application specificities.

Key Differences Between Kevlar Thread and Kevlar Fabric

Kevlar thread is composed of thin, continuous fibers designed for stitching and reinforcement in high-strength applications, while Kevlar fabric consists of woven or knitted layers that provide comprehensive protective barriers against impact and abrasion. Kevlar fabric offers multidirectional strength and is widely used in body armor, automotive, and aerospace industries, whereas Kevlar thread is primarily used for sewing Kevlar fabric or reinforcing composite materials. The key difference lies in their form and function: thread serves as a binding element with tensile strength, and fabric delivers broad surface protection and durability.

Composition and Manufacturing Process

Kevlar thread consists of spun filaments made from poly-para-phenylene terephthalamide, produced through a gel spinning process that aligns polymer chains for enhanced strength. Kevlar fabric is woven or knit from these high-tensile Kevlar threads, utilizing various weaving techniques such as plain, twill, or satin weaves to optimize flexibility and durability. The manufacturing process of Kevlar fabric involves tightly interlacing the threads to create a lightweight yet impact-resistant material used extensively in ballistic and protective applications.

Strength and Durability Comparison

Kevlar thread boasts exceptional tensile strength, making it ideal for reinforcing stitches in high-stress applications, while Kevlar fabric provides broader protective coverage with its woven structure that distributes impact forces evenly. Kevlar fabric exhibits superior durability against abrasion and puncture compared to individual Kevlar threads, ensuring enhanced resistance in ballistic and protective gear. The combination of Kevlar thread's strength and Kevlar fabric's toughness results in optimized performance for safety equipment and industrial uses.

Common Applications of Kevlar Thread

Kevlar thread is commonly used in the manufacturing of high-performance sewing applications, such as protective clothing, footwear, and sports gear, where exceptional tensile strength and cut resistance are required. Unlike Kevlar fabric, which forms the base material for bulletproof vests and composite reinforcements, Kevlar thread provides robust stitching that enhances durability in demanding environments like aerospace, military uniforms, and automotive airbags. Its ability to maintain strength under extreme conditions makes it indispensable for reinforcing seams in products subjected to high stress or abrasion.

Popular Uses for Kevlar Fabric

Kevlar fabric is widely used in protective gear such as bulletproof vests, helmets, and cut-resistant gloves due to its high tensile strength and lightweight properties. Its woven structure provides excellent resistance to abrasion and impact, making it ideal for military, law enforcement, and industrial applications. Unlike Kevlar thread, which is primarily used for stitching and reinforcement, Kevlar fabric serves as a critical material for creating durable, flexible, and protective outer layers.

Flexibility and Handling: Thread vs Fabric

Kevlar thread offers superior flexibility and ease of handling compared to Kevlar fabric, making it ideal for applications requiring intricate stitching and precise textile manipulation. Kevlar fabric, while highly durable and resistant to heat and abrasion, tends to be stiffer and less pliable, which can limit its adaptability in complex shapes or tight spaces. Selecting Kevlar thread enhances maneuverability in detailed projects, whereas Kevlar fabric excels in providing structural strength and protective layering.

Cost Efficiency and Availability

Kevlar thread offers greater cost efficiency due to its lower production complexity and is widely available for applications requiring high tensile strength in smaller quantities. Kevlar fabric, while more expensive, provides enhanced durability and abrasion resistance suited for large-scale protective gear and industrial uses, but its availability can be limited by manufacturing capacity. Choosing between Kevlar thread and fabric depends on balancing budget constraints with the specific performance requirements and supply accessibility of the project.

Choosing the Right Kevlar Material for Your Project

Kevlar thread offers superior tensile strength and flexibility, making it ideal for precise stitching and reinforcing specific areas in high-stress applications. Kevlar fabric provides broader coverage with exceptional abrasion resistance and impact protection, suitable for crafting protective gear and composite materials. Selecting the right Kevlar material depends on the project's requirements for durability, flexibility, and overall performance under extreme conditions.

Safety and Performance in Real-World Scenarios

Kevlar thread offers enhanced tensile strength and precision in stitching, ensuring critical seams maintain integrity under extreme stress, which directly impacts the overall safety of protective gear. Kevlar fabric provides broad-area resistance to cuts, abrasions, and ballistic threats, delivering comprehensive protection crucial for real-world scenarios like law enforcement and firefighting. Combining Kevlar thread with Kevlar fabric optimizes performance by reinforcing vulnerable points and maximizing durability in high-risk environments.

Kevlar Thread vs Kevlar Fabric Infographic

materialdif.com

materialdif.com