Kevlar laminate offers superior impact resistance and flexibility compared to aluminum laminate, making it ideal for high-performance pet gear that requires both durability and lightweight properties. Unlike aluminum, Kevlar laminate provides excellent abrasion resistance without compromising comfort, ensuring pet accessories remain intact during vigorous activities. The combination of strength and compliance in Kevlar laminate enhances safety and longevity over traditional aluminum laminates used in pet products.

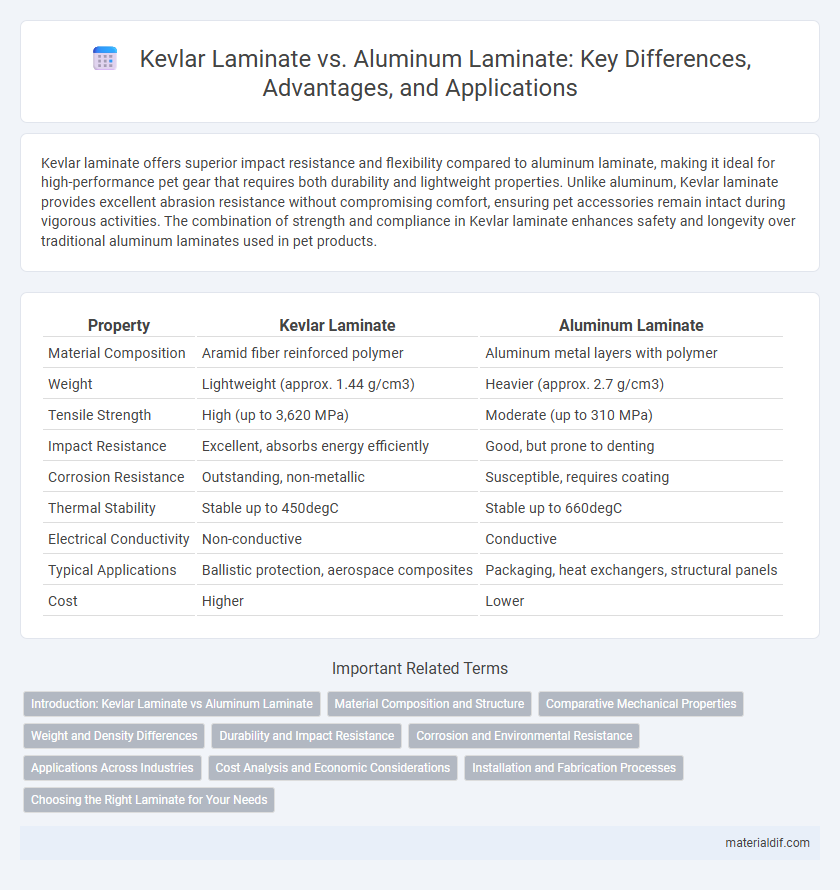

Table of Comparison

| Property | Kevlar Laminate | Aluminum Laminate |

|---|---|---|

| Material Composition | Aramid fiber reinforced polymer | Aluminum metal layers with polymer |

| Weight | Lightweight (approx. 1.44 g/cm3) | Heavier (approx. 2.7 g/cm3) |

| Tensile Strength | High (up to 3,620 MPa) | Moderate (up to 310 MPa) |

| Impact Resistance | Excellent, absorbs energy efficiently | Good, but prone to denting |

| Corrosion Resistance | Outstanding, non-metallic | Susceptible, requires coating |

| Thermal Stability | Stable up to 450degC | Stable up to 660degC |

| Electrical Conductivity | Non-conductive | Conductive |

| Typical Applications | Ballistic protection, aerospace composites | Packaging, heat exchangers, structural panels |

| Cost | Higher | Lower |

Introduction: Kevlar Laminate vs Aluminum Laminate

Kevlar laminate offers superior impact resistance and high tensile strength compared to aluminum laminate, making it ideal for lightweight protective applications. While aluminum laminate provides excellent rigidity and thermal conductivity, Kevlar laminate excels in energy absorption and flexibility. The unique molecular structure of Kevlar fibers contributes to enhanced durability and reduced weight in composite materials.

Material Composition and Structure

Kevlar laminate consists of tightly woven aramid fibers embedded in a polymer matrix, providing exceptional tensile strength and flexibility while maintaining lightweight properties. Aluminum laminate features thin layers of aluminum bonded to a substrate, offering superior stiffness and high resistance to impact and corrosion but with greater weight compared to Kevlar. The composite structure of Kevlar laminate optimizes energy absorption and durability, making it ideal for ballistic protection, whereas aluminum laminate excels in applications requiring structural rigidity and thermal conductivity.

Comparative Mechanical Properties

Kevlar laminate exhibits significantly higher tensile strength and impact resistance compared to aluminum laminate, making it ideal for applications requiring superior durability and energy absorption. Kevlar's low density contributes to a higher strength-to-weight ratio, enhancing performance in lightweight structural applications. Aluminum laminate, while offering better stiffness and thermal conductivity, cannot match Kevlar's elongation at break and fatigue resistance under cyclic loading conditions.

Weight and Density Differences

Kevlar laminate exhibits significantly lower density, approximately 1.44 g/cm3, compared to aluminum laminate's density of around 2.7 g/cm3, resulting in substantial weight savings in applications requiring lightweight materials. The reduced weight of Kevlar laminates enhances performance in aerospace and automotive industries by improving fuel efficiency and maneuverability. Despite being lighter, Kevlar laminates maintain excellent strength-to-weight ratios, making them preferred choices over aluminum in advanced composite structures.

Durability and Impact Resistance

Kevlar laminate outperforms aluminum laminate in durability due to its exceptional tensile strength and resistance to fatigue, making it ideal for applications requiring long-term structural integrity. Its high impact resistance stems from the ability to absorb and disperse energy efficiently, significantly reducing the risk of fracture compared to brittle aluminum laminates. Kevlar's lightweight nature combined with superior toughness provides enhanced protection in environments where both durability and impact resistance are critical.

Corrosion and Environmental Resistance

Kevlar laminate exhibits superior corrosion resistance compared to aluminum laminate due to its synthetic aramid fiber composition, which is inherently immune to oxidation and chemical degradation. Unlike aluminum laminates that are susceptible to corrosive environments and require protective coatings, Kevlar laminates maintain structural integrity in harsh chemicals, moisture, and saltwater exposure. This enhanced environmental resistance makes Kevlar laminates ideal for applications demanding long-term durability in aggressive conditions.

Applications Across Industries

Kevlar laminate exhibits superior impact resistance and lightweight properties, making it ideal for automotive, aerospace, and protective gear applications where durability and weight reduction are critical. Aluminum laminate offers enhanced thermal conductivity and corrosion resistance, favoring its use in electronics, packaging, and construction industries. The choice between Kevlar and aluminum laminates depends on balancing mechanical strength, weight, and environmental resistance specific to industry requirements.

Cost Analysis and Economic Considerations

Kevlar laminate offers superior strength-to-weight ratio and impact resistance compared to aluminum laminate, but typically comes at a higher upfront material cost. Aluminum laminates, while more affordable initially, may incur greater long-term expenses due to corrosion, maintenance, and lower durability in demanding environments. Economic considerations favor Kevlar laminate in applications prioritizing longevity and performance, whereas aluminum may be cost-effective for budget-sensitive projects with less rigorous requirements.

Installation and Fabrication Processes

Kevlar laminate offers a lightweight and flexible alternative to aluminum laminate, significantly simplifying installation and fabrication processes due to its ease of cutting and shaping without specialized tools. Unlike aluminum, Kevlar requires less energy-intensive handling and can be bonded using adhesives rather than mechanical fasteners, reducing labor time and costs. The enhanced impact resistance of Kevlar laminate also minimizes risk of damage during installation, making it ideal for applications demanding rapid deployment and minimal onsite adjustments.

Choosing the Right Laminate for Your Needs

Kevlar laminate offers superior impact resistance and lightweight properties compared to aluminum laminate, making it ideal for applications requiring enhanced durability without added weight. Aluminum laminate provides excellent rigidity and corrosion resistance but is heavier, which can affect performance in weight-sensitive projects. Selecting the right laminate depends on balancing factors such as strength, weight, environmental exposure, and cost to meet specific structural or protective requirements.

Kevlar laminate vs Aluminum laminate Infographic

materialdif.com

materialdif.com