Kevlar cord offers exceptional tensile strength and heat resistance, making it highly durable for pet collars and leashes exposed to rough conditions. Spectra cord, known for its ultra-lightweight and high-strength properties, provides excellent abrasion resistance and low stretch, ideal for pets requiring flexible yet strong gear. Both materials enhance safety and longevity, but Kevlar tends to outperform in extreme heat scenarios while Spectra excels in lightweight comfort.

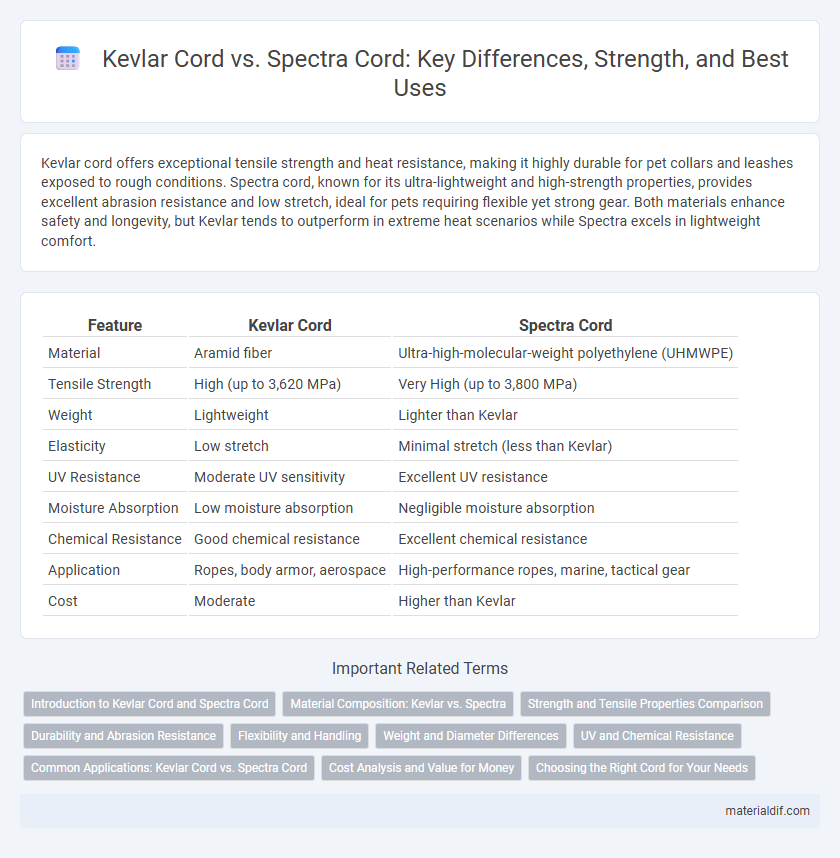

Table of Comparison

| Feature | Kevlar Cord | Spectra Cord |

|---|---|---|

| Material | Aramid fiber | Ultra-high-molecular-weight polyethylene (UHMWPE) |

| Tensile Strength | High (up to 3,620 MPa) | Very High (up to 3,800 MPa) |

| Weight | Lightweight | Lighter than Kevlar |

| Elasticity | Low stretch | Minimal stretch (less than Kevlar) |

| UV Resistance | Moderate UV sensitivity | Excellent UV resistance |

| Moisture Absorption | Low moisture absorption | Negligible moisture absorption |

| Chemical Resistance | Good chemical resistance | Excellent chemical resistance |

| Application | Ropes, body armor, aerospace | High-performance ropes, marine, tactical gear |

| Cost | Moderate | Higher than Kevlar |

Introduction to Kevlar Cord and Spectra Cord

Kevlar cord is a high-strength synthetic fiber known for its exceptional tensile strength, heat resistance, and durability, commonly used in applications requiring lightweight and robust materials. Spectra cord, made from ultra-high-molecular-weight polyethylene (UHMWPE), offers superior strength-to-weight ratio, excellent abrasion resistance, and low stretch properties ideal for high-performance uses. Both cords serve critical roles in industries such as marine, military, and safety equipment, with Kevlar excelling in thermal stability and Spectra providing enhanced flexibility and moisture resistance.

Material Composition: Kevlar vs. Spectra

Kevlar cord is made from aramid fibers known for their exceptional tensile strength and heat resistance, making it ideal for high-impact and high-temperature applications. Spectra cord consists of ultra-high-molecular-weight polyethylene (UHMWPE) fibers, providing superior strength-to-weight ratio and excellent resistance to moisture and chemicals. While Kevlar excels in thermal stability, Spectra outperforms in lightweight durability and abrasion resistance, influencing their specific use cases in safety and performance gear.

Strength and Tensile Properties Comparison

Kevlar cord exhibits high tensile strength and excellent resistance to abrasion, making it ideal for applications requiring durability under tension. Spectra cord, composed of ultra-high-molecular-weight polyethylene fibers, offers superior tensile strength-to-weight ratio and greater elongation before breaking compared to Kevlar. While Kevlar provides outstanding cut resistance and thermal stability, Spectra excels in tensile strength and flexibility, crucial factors in load-bearing and high-performance uses.

Durability and Abrasion Resistance

Kevlar cord offers superior durability due to its high tensile strength and resistance to heat and chemical degradation, making it ideal for demanding applications. In comparison, Spectra cord, while strong and lightweight, exhibits lower abrasion resistance and can wear down more quickly under harsh frictional conditions. Choosing Kevlar cord ensures longer-lasting performance in environments with constant mechanical stress and rough surfaces.

Flexibility and Handling

Kevlar cord exhibits higher stiffness compared to Spectra cord, resulting in less flexibility and a firmer handling experience. Spectra cord's ultra-high-molecular-weight polyethylene fibers provide superior flexibility, allowing easier manipulation and knotting during use. This flexibility advantage makes Spectra ideal for applications requiring frequent bending and intricate handling, while Kevlar excels in high-strength, low-elongation scenarios.

Weight and Diameter Differences

Kevlar cord is significantly heavier and has a larger diameter compared to Spectra cord, making it less suitable for applications where weight reduction and compactness are critical. Spectra cord's high strength-to-weight ratio and smaller diameter provide superior performance in lightweight gear and high-tension uses. The density of Kevlar, approximately 1.44 g/cm3, contributes to its increased weight, while Spectra's ultra-high-molecular-weight polyethylene composition offers a density near 0.97 g/cm3, allowing for thinner, lighter cords.

UV and Chemical Resistance

Kevlar cord excels in UV resistance, maintaining strength and durability when exposed to sunlight, unlike Spectra cord which degrades faster under UV radiation. Chemically, Kevlar withstands exposure to oils, solvents, and most acids better than Spectra, making it suitable for harsh environments. The superior UV and chemical resistance of Kevlar cord ensures long-term reliability in outdoor and industrial applications.

Common Applications: Kevlar Cord vs. Spectra Cord

Kevlar cord is widely used in applications requiring high tensile strength and thermal resistance, such as ballistic protection, marine rigging, and overhead power lines. Spectra cord, known for its ultra-high-strength-to-weight ratio and excellent abrasion resistance, is commonly applied in fishing lines, climbing ropes, and aerospace cables. Both materials serve critical roles in safety and performance-driven industries but differ in flexibility and environmental durability.

Cost Analysis and Value for Money

Kevlar cord generally offers higher tensile strength and superior heat resistance compared to Spectra cord, making it ideal for demanding applications despite its higher initial cost. Spectra cord is often more cost-effective due to lower manufacturing expenses and lighter weight, which reduces transportation and handling costs. Evaluating the cost per performance ratio, Kevlar cord provides better long-term value for applications requiring durability and extreme conditions, while Spectra is suitable for budget-sensitive uses with moderate strength requirements.

Choosing the Right Cord for Your Needs

Kevlar cord offers exceptional tensile strength and heat resistance, making it ideal for applications requiring durability in extreme conditions, while Spectra cord excels in lightweight, high-strength performance with excellent resistance to moisture and abrasion. Choosing the right cord depends on factors such as load capacity, environmental exposure, and flexibility requirements, with Kevlar favored for high-temperature or rugged environments and Spectra preferred in marine or wet conditions. Evaluating these material properties ensures optimal performance and longevity in your specific use case.

Kevlar cord vs Spectra cord Infographic

materialdif.com

materialdif.com