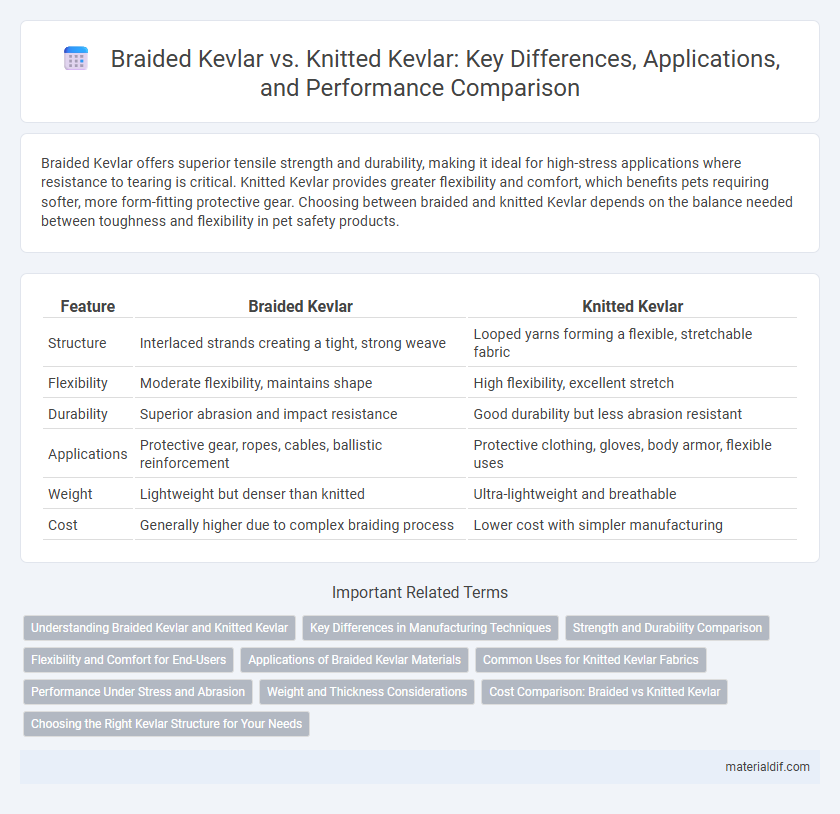

Braided Kevlar offers superior tensile strength and durability, making it ideal for high-stress applications where resistance to tearing is critical. Knitted Kevlar provides greater flexibility and comfort, which benefits pets requiring softer, more form-fitting protective gear. Choosing between braided and knitted Kevlar depends on the balance needed between toughness and flexibility in pet safety products.

Table of Comparison

| Feature | Braided Kevlar | Knitted Kevlar |

|---|---|---|

| Structure | Interlaced strands creating a tight, strong weave | Looped yarns forming a flexible, stretchable fabric |

| Flexibility | Moderate flexibility, maintains shape | High flexibility, excellent stretch |

| Durability | Superior abrasion and impact resistance | Good durability but less abrasion resistant |

| Applications | Protective gear, ropes, cables, ballistic reinforcement | Protective clothing, gloves, body armor, flexible uses |

| Weight | Lightweight but denser than knitted | Ultra-lightweight and breathable |

| Cost | Generally higher due to complex braiding process | Lower cost with simpler manufacturing |

Understanding Braided Kevlar and Knitted Kevlar

Braided Kevlar consists of interlaced fibers forming a tight, durable structure ideal for applications requiring high tensile strength and resistance to abrasion. Knitted Kevlar features loops of yarns interlocked in a pattern that offers superior flexibility and stretch, making it suitable for protective clothing that demands both comfort and mobility. Understanding the differences between braided and knitted Kevlar helps in selecting the right material based on the balance between strength, flexibility, and specific use-case requirements.

Key Differences in Manufacturing Techniques

Braided Kevlar consists of interlaced yarns forming a strong, flexible structure ideal for impact resistance and multidirectional strength. Knitted Kevlar, created by looping yarns in a continuous pattern, offers superior elasticity and comfort, making it suitable for protective clothing requiring flexibility. The manufacturing difference lies in the braiding technique using multiple strands intertwining tightly, whereas knitting employs a looping process that creates stretchable fabric with varied porosity.

Strength and Durability Comparison

Braided Kevlar offers superior tensile strength and enhanced durability due to the interwoven fiber pattern that distributes stress evenly, making it ideal for high-impact applications. Knitted Kevlar provides greater flexibility and stretchability but sacrifices some strength as its looped structure absorbs energy differently, resulting in lower resistance to abrasion and tearing. The choice between braided and knitted Kevlar depends on balancing the need for maximum strength with the requirement for flexibility in specific protective gear or industrial uses.

Flexibility and Comfort for End-Users

Braided Kevlar offers superior flexibility and durability, making it ideal for applications requiring consistent bending without compromising strength. Knitted Kevlar provides enhanced comfort and stretchability, adapting better to body movements for end-users in protective clothing. The choice between braided and knitted Kevlar ultimately depends on the balance needed between flexibility, comfort, and performance in specific use cases.

Applications of Braided Kevlar Materials

Braided Kevlar materials are extensively used in applications demanding high tensile strength and flexible protection, such as body armor, ballistic helmets, and reinforcement for ropes and cables. Their tightly interwoven structure provides enhanced abrasion resistance and structural integrity, making them ideal for aerospace components and automotive parts requiring lightweight durability. The versatile and robust nature of braided Kevlar also supports industrial uses, including conveyor belts and protective gloves in hazardous work environments.

Common Uses for Knitted Kevlar Fabrics

Knitted Kevlar fabrics are commonly used in applications requiring high flexibility and impact resistance, such as protective gloves, body armor liners, and flexible ballistic inserts. Their stretchable structure provides enhanced comfort and mobility, making them suitable for garments and equipment that demand both protection and dexterity. This versatility in protective wear highlights knitted Kevlar's role in industries like law enforcement, military, and high-performance sports.

Performance Under Stress and Abrasion

Braided Kevlar exhibits superior tensile strength and resistance to elongation under stress, making it ideal for high-load applications where durability is critical. Knitted Kevlar offers enhanced flexibility and better abrasion resistance due to its interlocking loops that distribute friction more evenly across the fabric. Performance under repetitive mechanical stress favors braided Kevlar for structural integrity, while knitted Kevlar excels in applications requiring flexibility and extended wear in abrasive conditions.

Weight and Thickness Considerations

Braided Kevlar typically offers higher strength-to-weight ratios with a denser weave, resulting in greater thickness and durability suitable for heavy-duty applications. In contrast, knitted Kevlar is lighter and more flexible, reducing thickness and overall weight, making it ideal for garments requiring enhanced mobility and comfort. Selecting between braided and knitted Kevlar depends on weight constraints and protective requirements specific to the intended use.

Cost Comparison: Braided vs Knitted Kevlar

Braided Kevlar generally incurs higher production costs due to its complex weaving process that enhances tensile strength and durability, making it ideal for heavy-duty applications. Knitted Kevlar, being less labor-intensive to manufacture, offers a more cost-effective alternative suitable for flexible, lightweight protective gear. The choice between braided and knitted Kevlar depends on balancing budget constraints with the required performance characteristics for specific uses.

Choosing the Right Kevlar Structure for Your Needs

Braided Kevlar offers superior strength and resistance to abrasion, making it ideal for applications requiring high durability and load-bearing capacity, such as bulletproof vests and industrial cables. Knitted Kevlar provides greater flexibility and elasticity, suited for protective clothing and gear that demands comfort and movement without sacrificing safety. Selecting between braided and knitted Kevlar depends on whether the priority is maximum toughness or adaptability to dynamic shapes and motions.

Braided Kevlar vs Knitted Kevlar Infographic

materialdif.com

materialdif.com