Knitted Kevlar offers enhanced flexibility and stretch, making it ideal for pet products that require comfort and ease of movement. Woven Kevlar provides superior strength and durability, suitable for high-impact protection and abrasion resistance in pet gear. Selecting between knitted and woven Kevlar depends on balancing flexibility needs with protection requirements for your pet.

Table of Comparison

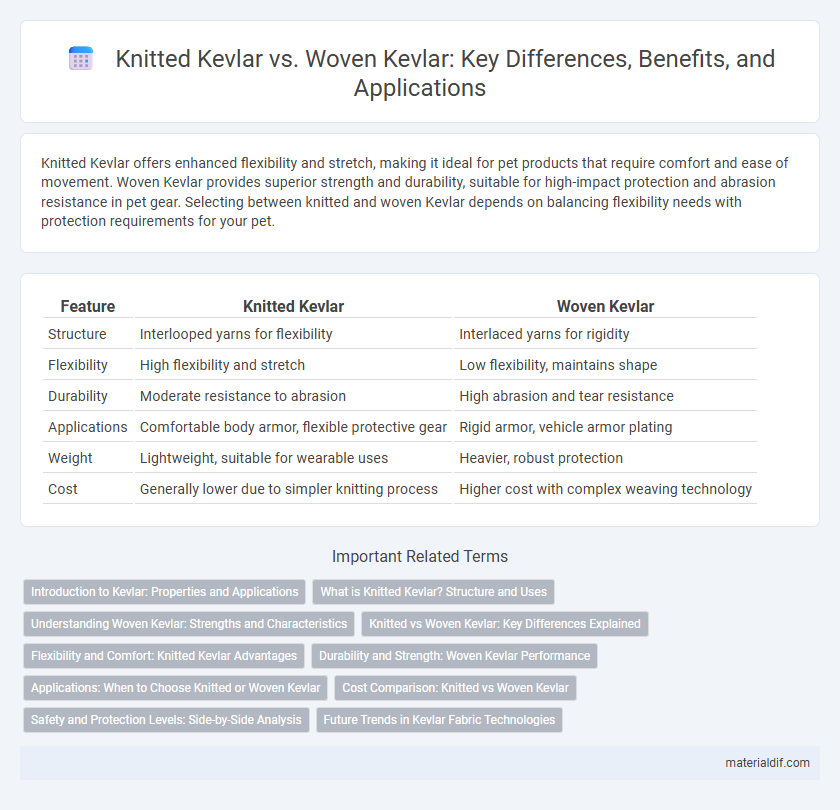

| Feature | Knitted Kevlar | Woven Kevlar |

|---|---|---|

| Structure | Interlooped yarns for flexibility | Interlaced yarns for rigidity |

| Flexibility | High flexibility and stretch | Low flexibility, maintains shape |

| Durability | Moderate resistance to abrasion | High abrasion and tear resistance |

| Applications | Comfortable body armor, flexible protective gear | Rigid armor, vehicle armor plating |

| Weight | Lightweight, suitable for wearable uses | Heavier, robust protection |

| Cost | Generally lower due to simpler knitting process | Higher cost with complex weaving technology |

Introduction to Kevlar: Properties and Applications

Kevlar is a high-strength aramid fiber known for its exceptional tensile strength, heat resistance, and lightweight properties, making it ideal for protective gear and industrial applications. Knitted Kevlar offers enhanced flexibility and conformability, suitable for body armor and gloves, while woven Kevlar provides superior structural strength and durability, commonly used in ballistic vests and composite materials. Both forms leverage Kevlar's inherent resistance to abrasion and impact, optimizing performance based on specific application requirements.

What is Knitted Kevlar? Structure and Uses

Knitted Kevlar consists of interlooped yarns creating a flexible, stretchable fabric that enhances comfort and contouring in protective gear. Its structure allows for improved impact absorption and breathability compared to woven Kevlar, making it ideal for gloves, body armor, and sportswear requiring flexibility and durability. Knitted Kevlar is widely used in applications where mobility and lightweight protection are critical, balancing resistance to cuts, abrasions, and ballistic threats.

Understanding Woven Kevlar: Strengths and Characteristics

Woven Kevlar features interlaced fibers creating a tight, uniform fabric that offers excellent tensile strength and resistance to abrasion, making it ideal for ballistic protection and industrial applications. Its structured weave enhances durability and impact resistance by distributing forces evenly across the material. Compared to knitted Kevlar, woven Kevlar provides superior dimensional stability and consistent performance under high-stress conditions.

Knitted vs Woven Kevlar: Key Differences Explained

Knitted Kevlar features interlocking loops of fibers, providing greater flexibility, stretch, and comfort, which makes it ideal for applications requiring high mobility such as protective clothing and gloves. Woven Kevlar consists of tightly interlaced fiber yarns in a crisscross pattern, offering superior strength, rigidity, and abrasion resistance often used in ballistic armor and reinforced composites. The key differences lie in flexibility versus strength; knitted Kevlar balances wearability with protection, while woven Kevlar delivers maximum structural integrity and durability.

Flexibility and Comfort: Knitted Kevlar Advantages

Knitted Kevlar offers superior flexibility and comfort compared to woven Kevlar due to its looped construction, which allows for greater stretch and movement. This enhanced flexibility makes knitted Kevlar ideal for applications requiring dynamic motion and prolonged wear, such as protective clothing and gloves. The breathable nature of knitted Kevlar also improves moisture wicking and reduces heat retention, further boosting wearer comfort.

Durability and Strength: Woven Kevlar Performance

Woven Kevlar exhibits superior durability and strength compared to knitted Kevlar due to its tightly interlaced fiber structure, which enhances resistance to abrasion and impact. The uniform weave pattern in woven Kevlar maintains consistent mechanical properties, making it ideal for ballistic and protective applications. Its enhanced tensile strength and puncture resistance establish woven Kevlar as the preferred choice for high-performance body armor and industrial protective gear.

Applications: When to Choose Knitted or Woven Kevlar

Knitted Kevlar offers superior flexibility and stretch, making it ideal for applications requiring impact protection with enhanced mobility, such as protective gloves and sportswear. Woven Kevlar provides greater structural rigidity and high tensile strength, suited for ballistic armor, helmets, and industrial reinforcement where durability and resistance to penetration are critical. Selecting between knitted or woven Kevlar depends on the balance between flexibility and strength needed for specific protective gear or industrial use.

Cost Comparison: Knitted vs Woven Kevlar

Knitted Kevlar generally incurs higher production costs than woven Kevlar due to the complex knitting machinery and slower manufacturing speed. Woven Kevlar benefits from established loom technologies, resulting in lower material waste and reduced labor expenses. Cost analysis reveals woven Kevlar offers a more economical option for large-scale applications without compromising tensile strength.

Safety and Protection Levels: Side-by-Side Analysis

Knitted Kevlar offers greater flexibility and breathability, making it ideal for applications needing enhanced comfort without compromising basic protection, whereas woven Kevlar delivers superior tensile strength and cut resistance, providing higher levels of ballistic and stab protection. Woven Kevlar's tightly interlaced fibers create denser fabrics that enhance safety in high-threat environments such as military and law enforcement, while knitted variants excel in ergonomics for less intense protective gear. Choosing between knitted and woven Kevlar depends on the balance between protection level requirements and mobility needs in specific safety applications.

Future Trends in Kevlar Fabric Technologies

Knitted Kevlar offers enhanced flexibility and contouring capabilities compared to traditional woven Kevlar, making it ideal for next-generation lightweight armor and wearable protection. Emerging trends focus on hybrid fabrics combining knitted and woven structures to optimize ballistic resistance and comfort simultaneously. Innovations in nanotechnology integration and advanced fiber treatments are driving the evolution of Kevlar fabrics toward higher durability and multifunctional performance.

Knitted Kevlar vs Woven Kevlar Infographic

materialdif.com

materialdif.com