Kevlar felt offers a dense, non-woven structure that provides excellent thermal insulation and cushioning for pet products, while Kevlar fabric features a woven design that delivers superior tensile strength and abrasion resistance. The choice between Kevlar felt and Kevlar fabric depends on whether flexibility and padding or durability and protective layering are prioritized in pet gear. Both materials leverage Kevlar's inherent toughness, making them ideal for enhancing safety and comfort in pet accessories.

Table of Comparison

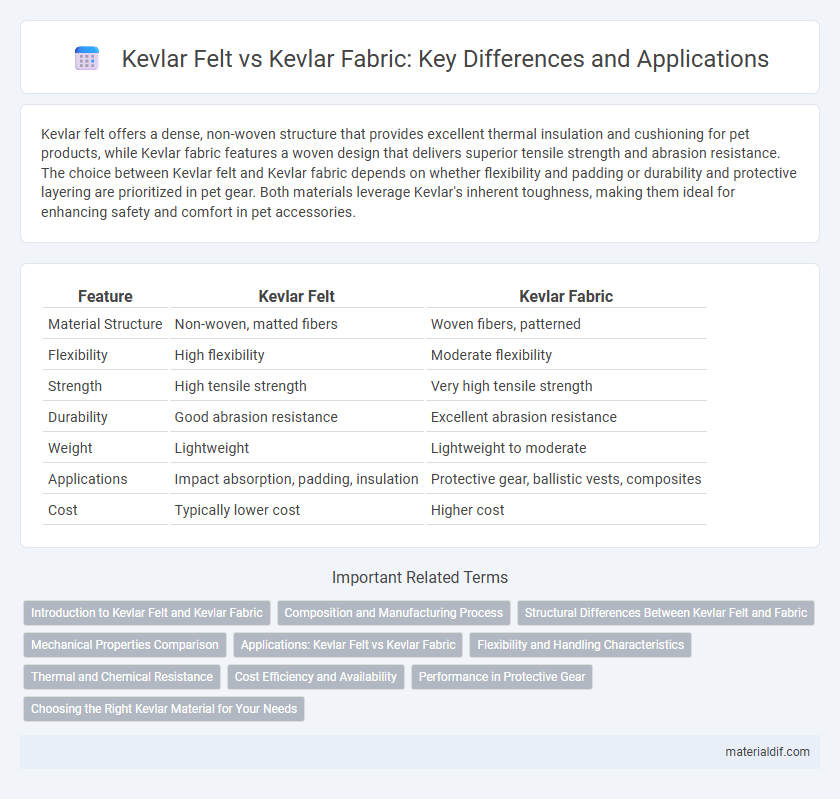

| Feature | Kevlar Felt | Kevlar Fabric |

|---|---|---|

| Material Structure | Non-woven, matted fibers | Woven fibers, patterned |

| Flexibility | High flexibility | Moderate flexibility |

| Strength | High tensile strength | Very high tensile strength |

| Durability | Good abrasion resistance | Excellent abrasion resistance |

| Weight | Lightweight | Lightweight to moderate |

| Applications | Impact absorption, padding, insulation | Protective gear, ballistic vests, composites |

| Cost | Typically lower cost | Higher cost |

Introduction to Kevlar Felt and Kevlar Fabric

Kevlar felt and Kevlar fabric are both produced from Kevlar fibers but differ in structure and applications. Kevlar felt is a non-woven material characterized by a dense, matted web of fibers offering superior thermal insulation and impact resistance, commonly used in gaskets and protective padding. Kevlar fabric, a woven material, provides high tensile strength and flexibility, making it ideal for bulletproof vests, protective clothing, and industrial reinforcement.

Composition and Manufacturing Process

Kevlar Felt is composed of randomly oriented Kevlar fibers bonded together through a needle-punching or hydroentangling process, resulting in a non-woven material with enhanced insulation and filtration properties. Kevlar Fabric consists of woven Kevlar yarns arranged in a specific pattern such as plain, twill, or satin weave, created through traditional weaving methods that ensure tensile strength and durability. The manufacturing process differences between felt and fabric influence their structural integrity, flexibility, and end-use performance in applications requiring impact resistance or thermal stability.

Structural Differences Between Kevlar Felt and Fabric

Kevlar felt consists of randomly oriented fibers compressed into a dense mat, providing excellent impact absorption and thermal insulation properties. Kevlar fabric features woven or knitted fibers arranged in a precise pattern, offering superior tensile strength and flexibility for applications requiring high durability. The structural differences between felt and fabric directly influence their mechanical properties and suitability for specific protective gear or industrial uses.

Mechanical Properties Comparison

Kevlar Felt offers superior impact absorption and sound dampening due to its non-woven, randomly oriented fibers, providing enhanced multi-directional strength compared to woven Kevlar Fabric. Kevlar Fabric, characterized by its tightly woven structure, delivers higher tensile strength and dimensional stability, making it ideal for applications requiring precise load-bearing capabilities. The mechanical properties of Kevlar Felt prioritize flexibility and energy dispersion, whereas Kevlar Fabric excels in durability and resistance to abrasion under repetitive stress.

Applications: Kevlar Felt vs Kevlar Fabric

Kevlar felt offers superior thermal insulation and cushioning, making it ideal for applications in protective padding, soundproofing, and filtration systems where flexibility and impact absorption are critical. Kevlar fabric provides high tensile strength and abrasion resistance, commonly used in ballistic armor, motorcycle gear, and aerospace components where durability and structural integrity are essential. Choosing between Kevlar felt and Kevlar fabric depends on specific function requirements such as thermal management or mechanical protection.

Flexibility and Handling Characteristics

Kevlar felt offers superior flexibility and conformability compared to Kevlar fabric, making it ideal for applications requiring easy molding around complex shapes. Kevlar fabric, woven with high tensile strength fibers, provides greater structural integrity but is less pliable, resulting in stiffer handling characteristics. The non-woven structure of Kevlar felt enhances its cushioning properties and ease of manipulation during assembly processes.

Thermal and Chemical Resistance

Kevlar felt offers superior thermal insulation due to its dense, non-woven structure, effectively withstanding temperatures up to 450degC while providing excellent chemical resistance against acids and solvents. Kevlar fabric, woven from high-tensile fibers, combines mechanical strength with resistance to heat and chemicals but typically allows more air permeability, which can reduce thermal insulation performance. Both materials excel in extreme environments, yet Kevlar felt is preferred for applications demanding enhanced thermal barriers and chemical protection.

Cost Efficiency and Availability

Kevlar Felt offers a cost-efficient alternative to Kevlar Fabric due to simpler manufacturing processes and lower material density, reducing overall expenses for bulk applications. Kevlar Fabric, while more expensive, provides superior tensile strength and durability, making it essential for high-performance uses despite its higher price. In terms of availability, Kevlar Fabric is more widely produced and accessible globally, whereas Kevlar Felt is less common and typically sourced for specialized industrial needs.

Performance in Protective Gear

Kevlar Felt offers superior impact absorption and thermal insulation compared to Kevlar Fabric, making it ideal for high-performance protective gear requiring enhanced shock resistance. Kevlar Fabric provides greater flexibility and tensile strength, suited for applications where durability and mobility are critical. Performance in protective gear depends on selecting Kevlar Felt for padding layers and Kevlar Fabric for outer protective shells to optimize safety and comfort.

Choosing the Right Kevlar Material for Your Needs

Kevlar Felt offers a denser, more cushioned material ideal for impact absorption and thermal insulation, making it suitable for protective padding and soundproofing. Kevlar Fabric provides a woven structure that excels in flexibility and tensile strength, perfect for lightweight body armor, gloves, and composite reinforcement. Selecting the right Kevlar material depends on the balance between protection level, flexibility, and specific application requirements such as durability and weight.

Kevlar Felt vs Kevlar Fabric Infographic

materialdif.com

materialdif.com